About ultrasonic flowmeter installation and installation mode

The installation of ultrasonic flowmeter is relatively simple and fast compared with other meters. However, the flowmeter manufacturer has to remind you that no matter how well the flowmeter is installed, it should also follow the installation requirements during the installation process.

1, the installation should pay attention to the steps

1) Observe whether the pipe at the installation site meets the requirements of the distance between the first 10D and the last 5D of the straight pipe section and the distance from the pump for 30D (D is the inner diameter of the pipe).

2) Confirm the fluid medium in the pipe and whether the pipe is full;

3) Confirm the pipe material and wall thickness;

4) After the first three steps are completed, you can confirm which sensor to use for installation;

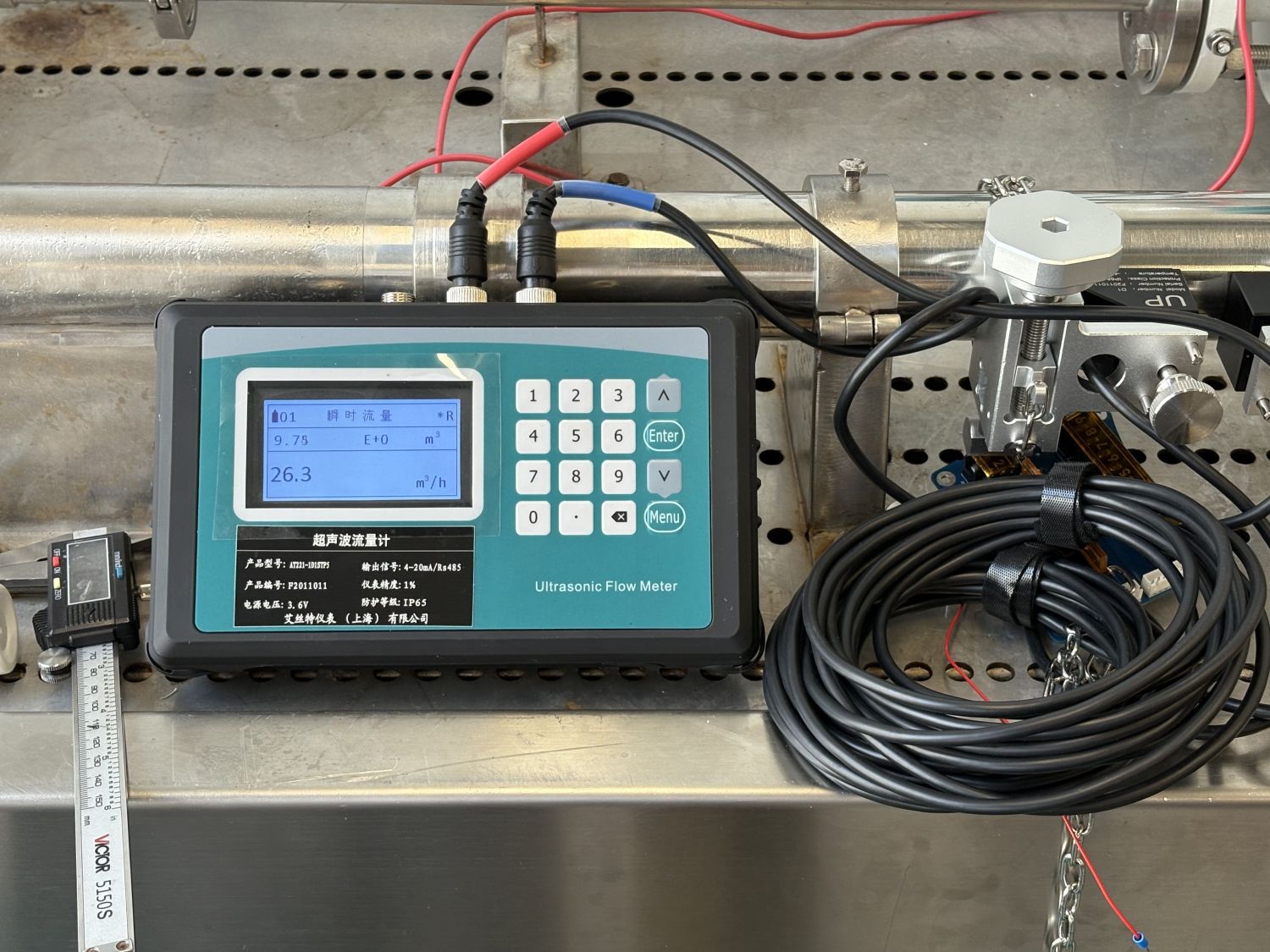

5) After the sensor is selected, start to input parameters to the table body to determine the installation distance;

6) It is important to measure the installation distance.

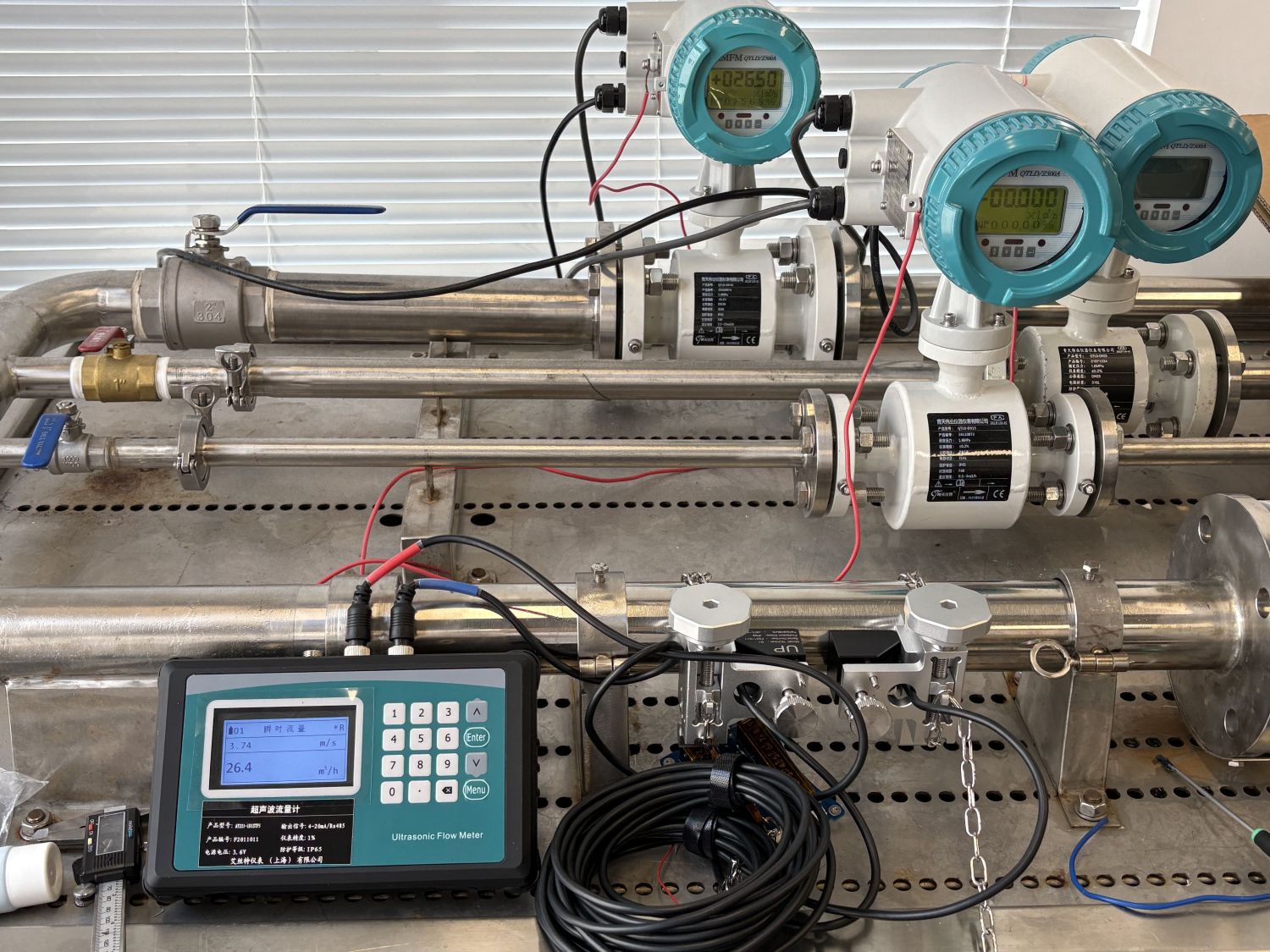

2. Installation method

Before installing the probe, we must first determine the measurement position and installation method, usually using the V method measurement, when the turbidity of the measured liquid is high, the strength of the received signal is weak when using the Z method measurement, so that the received is a strong direct refraction signal, which is conducive to the stability of the instrument.

1) Z-type installation

“Z” type installation is generally suitable for water pipeline thick or water medium is not very clean or the inner wall of the pipeline scale and make the “V” type installation signal distortion, generally speaking, more than 300 mm pipe diameter of the water pipeline selection “Z” type installation is more suitable, “Z” type installation of the measurable diameter range is usually 100 ~ 600 mm. When installing the sensor (probe), it must be noted that the upstream and downstream sensors (probe) are in the same plane as the water pipeline axis, and the downstream sensor (probe) is in the low position and the upstream sensor (probe) is in the high position.

2) V-type installation

The “V” type installation is the standard installation method and can be measured in the diameter range of 25 to 400 mm. When installing the sensor (probe), pay attention to the horizontal alignment of the upstream and downstream sensors (probe), so that the central connection is consistent with the water pipeline axis.