Analysis of the requirements for the measured medium of vortex flowmeters

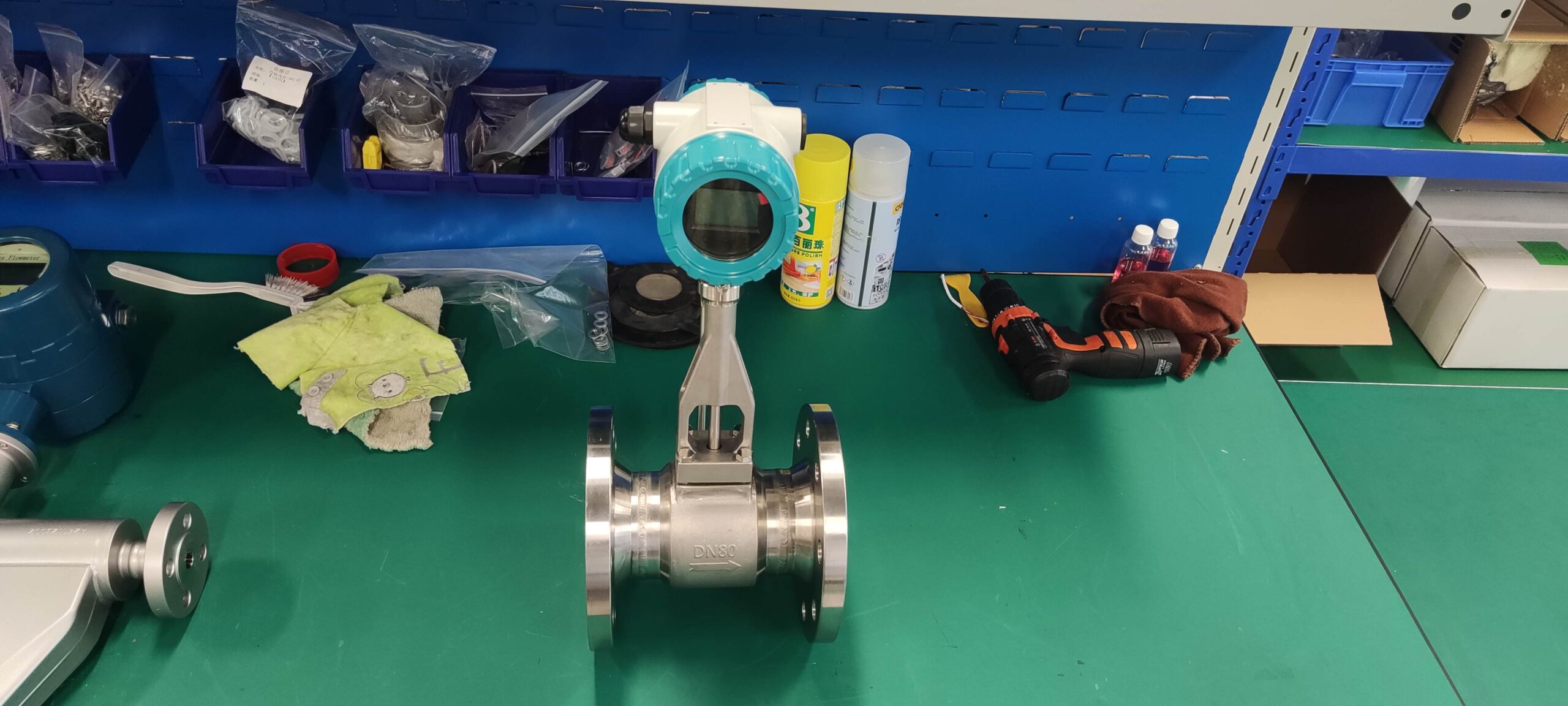

Vortex flowmeters are widely used in the measurement of steam, gas and liquid flow due to their advantages such as simple structure, good stability and wide range ratio. However, its measurement accuracy is closely related to the characteristics of the medium. If the medium does not meet the requirements, it may lead to measurement errors or even damage to the instrument. This article will conduct a detailed analysis of the key requirements of vortex flowmeters for the measured medium, assisting users in correct selection and application.

I. Requirements for Medium State

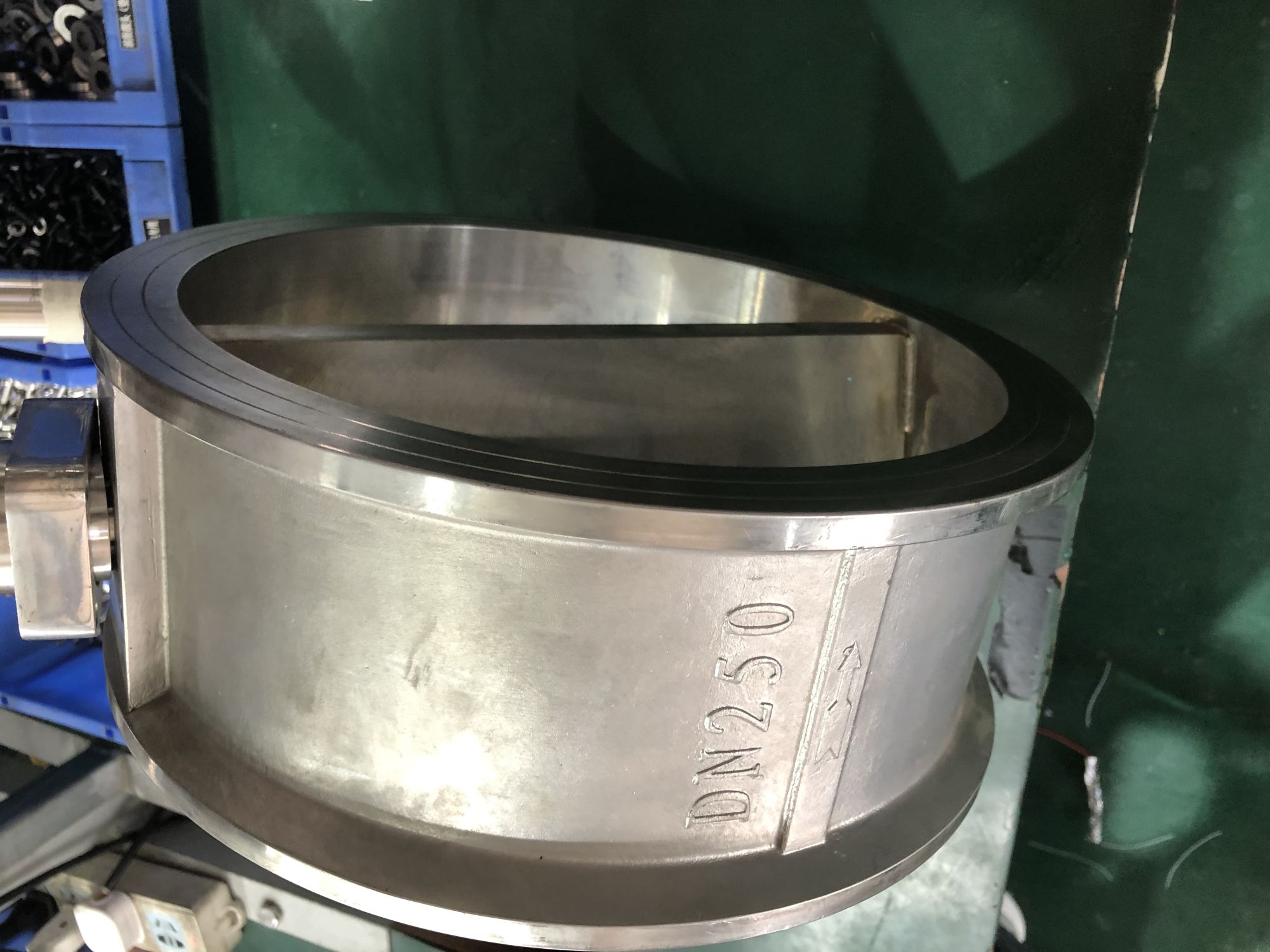

Single-phase flow (pure liquid, pure gas or pure vapor)

The vortex flowmeter is based on the Karman vortex street principle and requires the medium to be a uniform single-phase flow. If there is a gas-liquid mixture (such as wet steam) or a solid-liquid mixture (such as liquid containing particles) in the medium, the frequency of vortex street shedding will be disturbed, leading to inaccurate measurement.

2. Fully developed turbulence

Vortex flowmeters require the medium flow state to be turbulent (Reynolds number Re > 10⁴) to ensure a stable vortex signal. Laminar flow (low flow rate or high viscosity medium) may result in weak signals or no signal output.

Ii. Physical Property Requirements

Viscosity limit

Liquid medium: Excessively high viscosity (such as heavy oil, asphalt) will inhibit the formation of vortex streets and affect measurement accuracy. Generally, the dynamic viscosity is required to be less than 30mPa·s.

Gas/vapor medium: Viscosity has a relatively small impact, but it should be noted that low-density gases (such as hydrogen) may have a weaker signal.

2. Cleanliness requirements

If the medium contains solid particles, fibers or easily crystallized substances, it may clog the vortex generator or wear out the probe, and a filter needs to be installed. Corrosion-resistant materials (such as Hastelloy) should be selected for corrosive media.

3. Temperature and pressure range

Temperature: Typically -40℃ to 400℃. For extremely high temperatures, special models (such as those with heat sinks) should be selected.

Pressure: Conventional pressure resistance ≤4MPa. Customization is required for high-pressure media.

Iii. Requirements for Flow Characteristics

Flow rate range

Liquid: It is recommended to be 0.5 to 7m/s. If it is too low, it is prone to interference; if it is too high, cavitation may occur.

Gas/vapor: It is recommended to be 4 to 60m/s. The signal is weak at low speeds, and overspeed may damage the generator.

2. Full pipe state

When measuring liquids, it is necessary to ensure that the pipeline is full. For gases/vapors, liquid droplets should be prevented from mixing in. When installed vertically, gas should flow from bottom to top and liquid from top to bottom.

Iv. Examples of Unsuitable Media

High-viscosity liquids (such as honey, glue

Two-phase flow media (such as sparkling water, wet steam

Strong corrosive media (such as concentrated acids and alkalis, unless made of special materials)

Media containing a large amount of impurities (such as mud and sewage)

V. Selection Suggestions

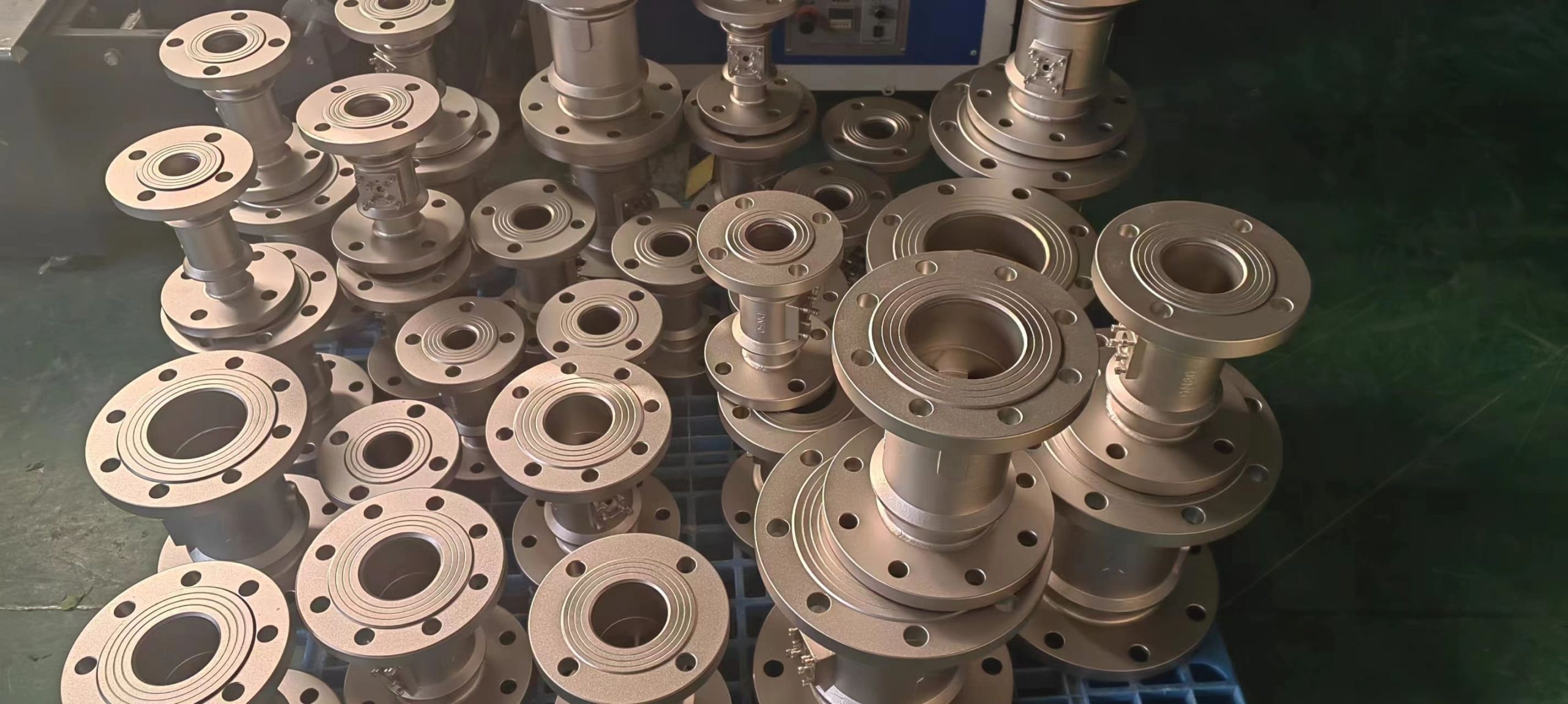

Clarify the medium parameters: including density, viscosity, temperature, pressure and cleanliness.

Special medium treatment: Install filters, rectifiers or choose a split structure.

Installation optimization: Ensure straight pipe sections at both the front and rear (10D before and 5D after) to avoid vibration interference.