What are the common faults of intelligent split-type sewage electromagnetic flowmeters

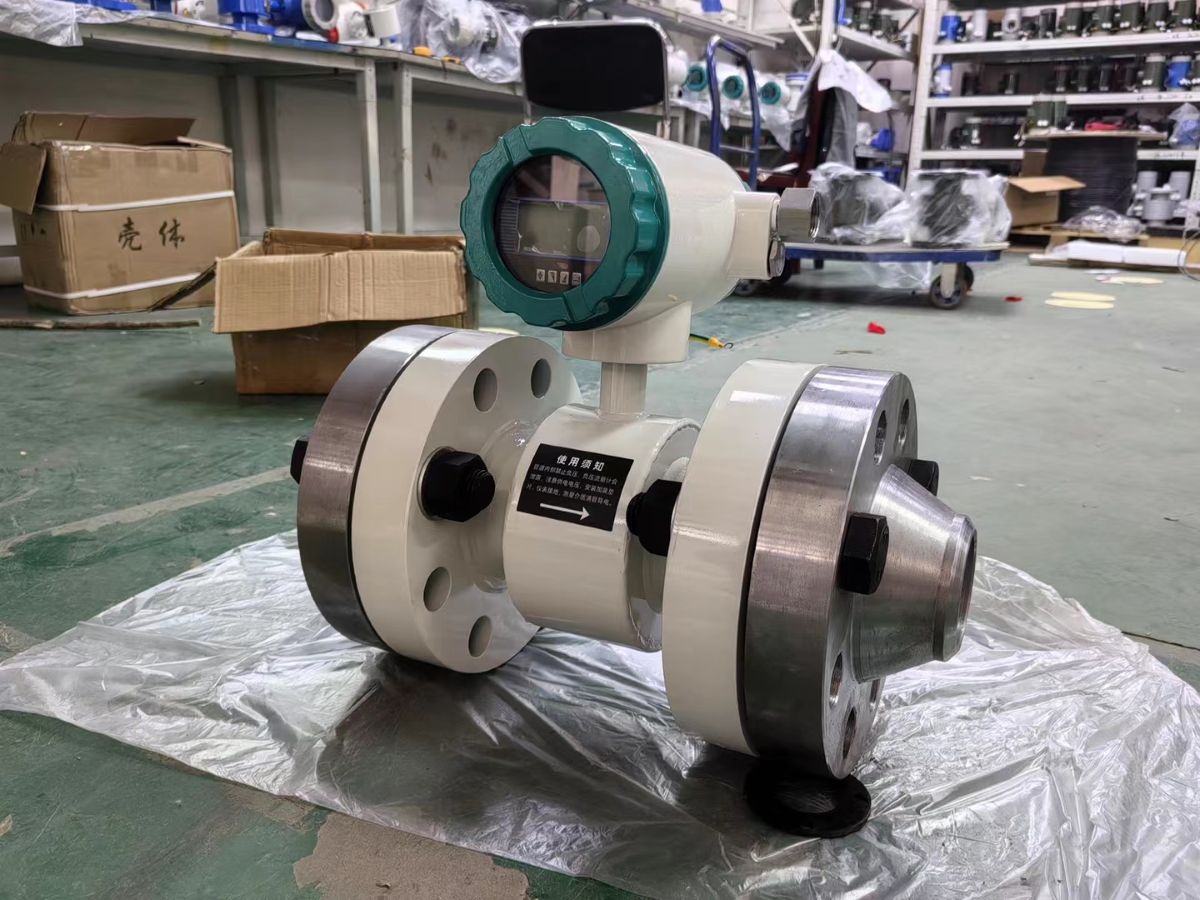

During the production and operation of the intelligent split-type sewage electromagnetic flowmeter, various faults may occur. 1. Instrument indication errors caused by faults in the instrument itself, including damage to the structural components or parts of the instrument, etc.

During the production and operation of the intelligent split-type sewage electromagnetic flowmeter, various faults may occur. 1. Instrument indication errors caused by faults in the instrument itself, including damage to the structural components or parts of the instrument, etc. 2. The faults are caused by the installation environment of the instrument or improper installation, such as the straight pipe sections installed upstream and downstream of the sensor not meeting the requirements, the measured medium not filling the pipeline, and the measurement environment having electromagnetic interference, etc.

Because the corresponding solutions to faults in different situations are different, in order to quantify faults more accurately and detect and solve faults of electromagnetic flowmeters more quickly, the faults of electromagnetic flowmeters are classified into two basic categories according to the time scale of fault occurrence. One type is the faults that occur during the installation and testing of the instrument, and the other type is the faults that occur after the instrument is put into operation.

To enhance the service life of the intelligent split-type sewage electromagnetic flowmeter and reduce the probability of its failure, the daily maintenance of the electromagnetic flowmeter mainly includes the following aspects

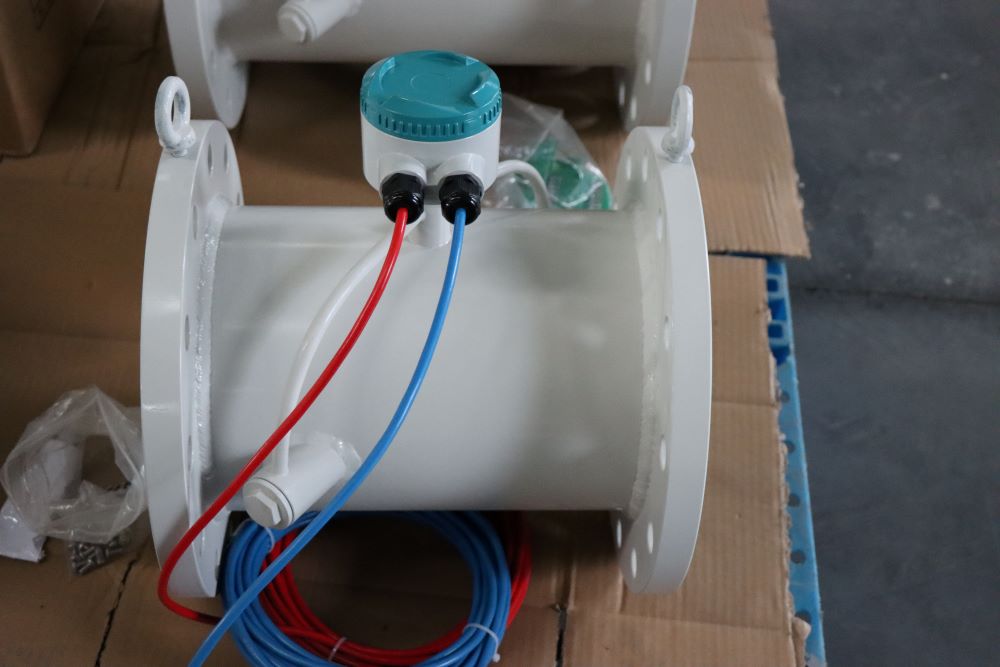

Regular cleaning of the scale layer on the inner wall of the transmitter tube can effectively ensure the good insulation of the insulating lining.

2. In actual production, regular inspection of instruments is the key to ensuring the indication accuracy of electromagnetic flowmeters, especially the inspection of the sealing of the instrument end cover and wiring ports, which is an important step to prevent moisture and water from entering the instrument. In addition, to ensure the high sealing performance of the instrument, the threads of the shell cover should always be coated with lubricating grease and must not be damaged by collision.

3. During the operation of the flowmeter, regularly calibrate the zero point of the instrument and ensure the effective grounding of the electromagnetic flowmeter.

-.jpg)

-.jpg)

-.jpg)