Classification of split electromagnetic flow meters

According to different working conditions, split electromagnetic flowmeters can be divided into the following types:

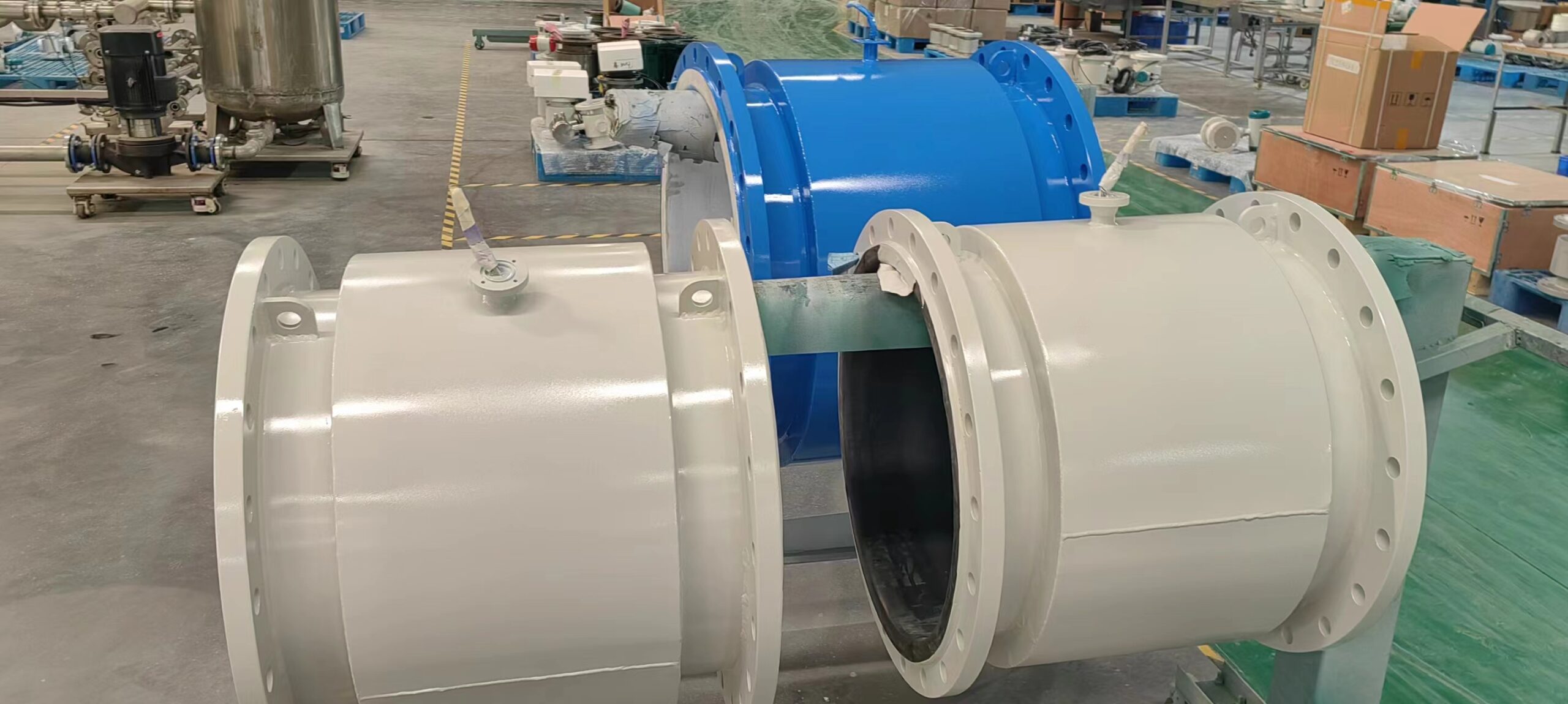

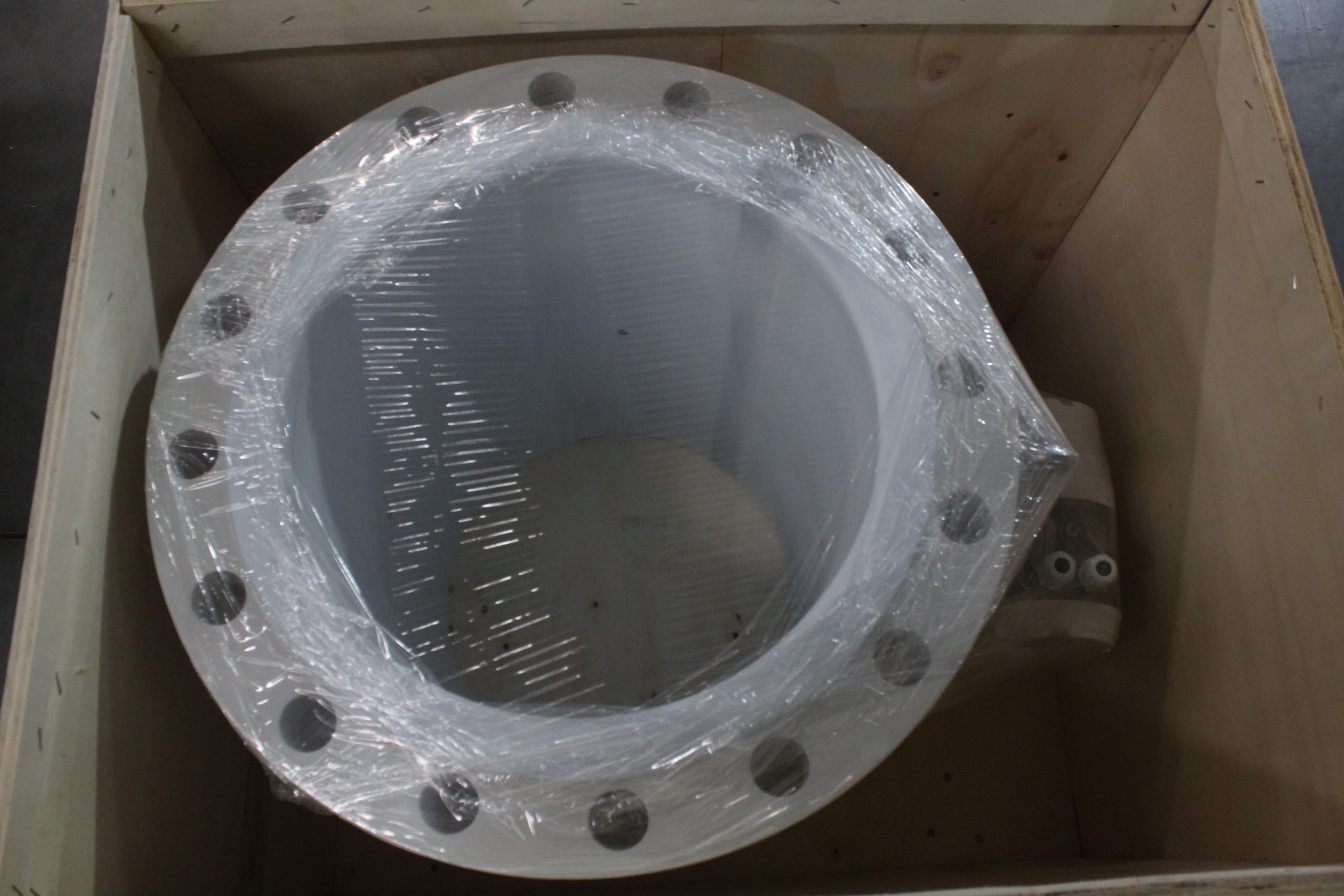

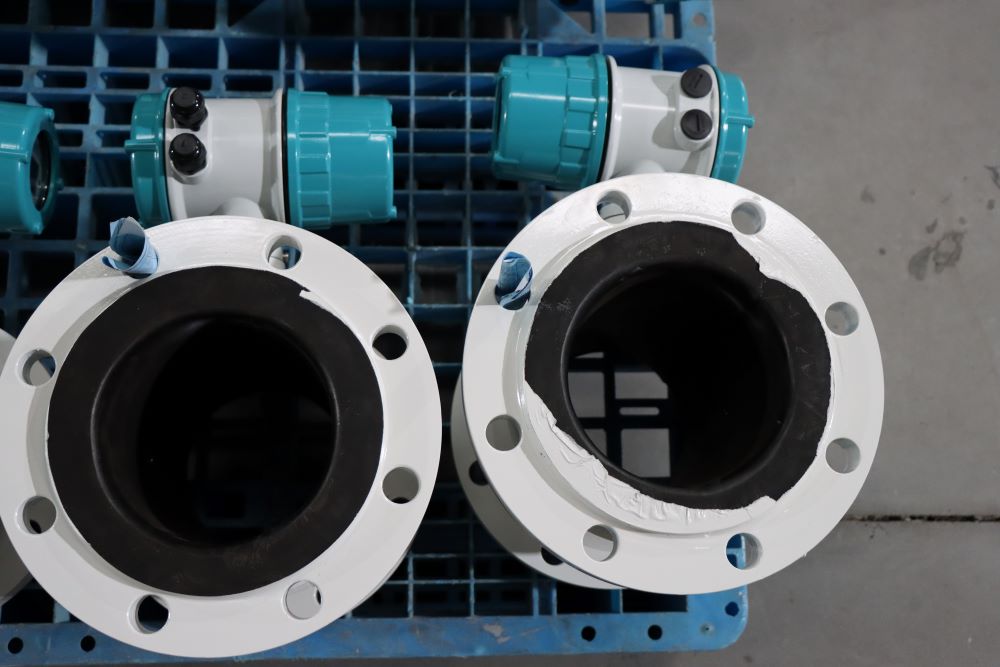

1, in metallurgy, paper making, sewage treatment and other industries, electromagnetic flowmeters are generally separated, large diameter flange connection type; In the biomedical, chemical and other industries, there are more small-caliber, one-body clamp connection methods, and the specifications of electromagnetic flowmeters required in different fields are not the same.

2, in some explosion-proof occasions, the instrument needs to have good explosion-proof and fire-proof performance, in these occasions, the energy of the excitation current is very large, electromagnetic flowmeter can be divided into airtight type, diaphragm type and sand filling type. With the rapid development of science and technology, now the power of the excitation current has decreased a lot, so the flowmeter is a safe spark type, which is composed of the sensing part and the conversion part of the flow, mainly used in the dangerous area.

3, such as food hygiene, medicine and other industries, the sensor of the electromagnetic flowmeter is easy to be disassembled, so that it is also convenient to clean, and it is easy to steam sterilization on a regular basis. Therefore, in the health industry, the electromagnetic flowmeter should meet the hygienic specifications.

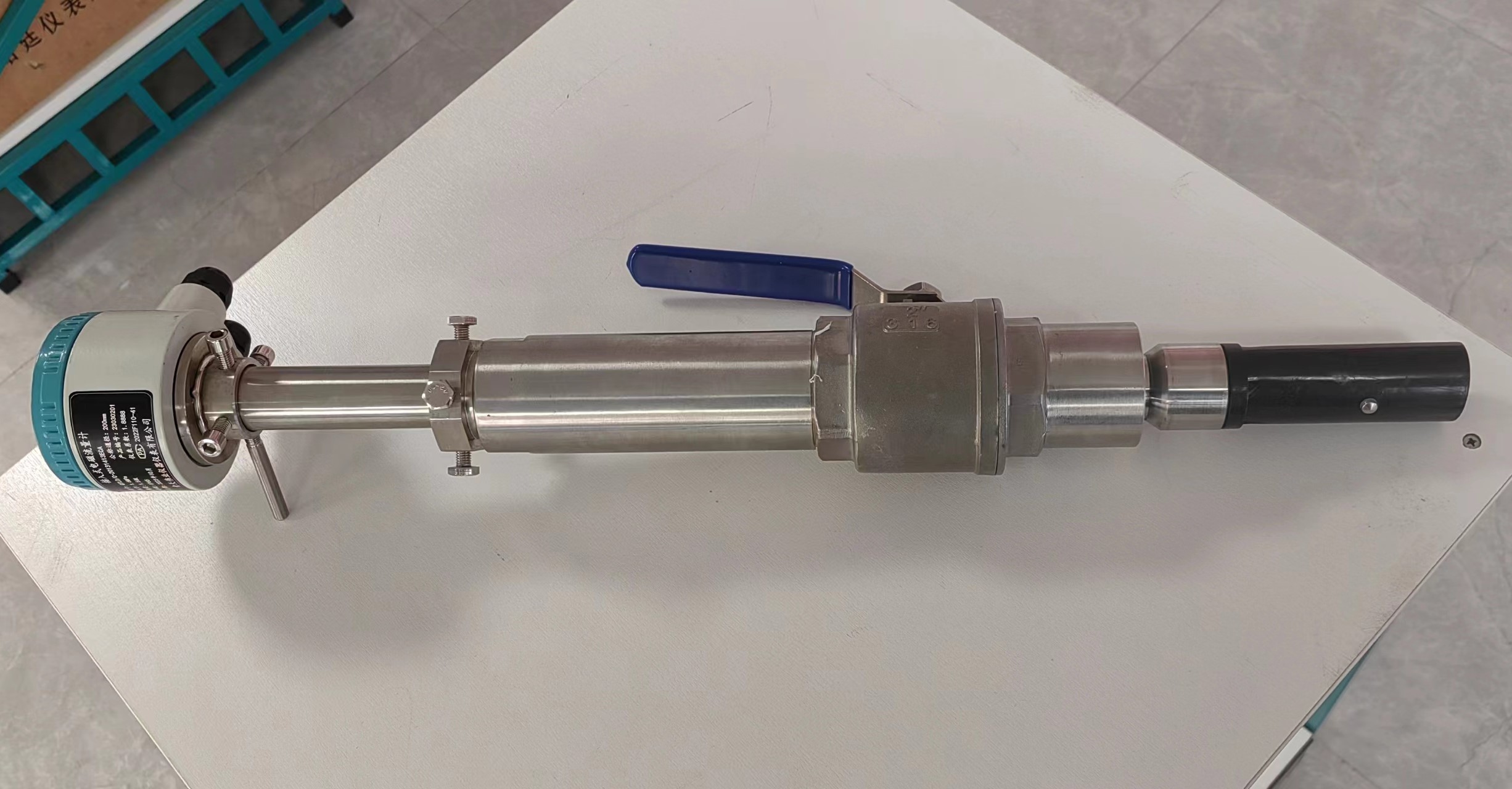

4, the instrument used in the channel is a submersible type, mainly for industrial drainage and sewer, they have to use the power of the hoist to carry out related drainage work. At the same time, the sensor of the electromagnetic flowmeter should be installed under the baffle plate of the open channel, and it should be soaked in water for a long time.

-.jpg)