How to use sewage flowmeters efficiently

Sewage treatment is one of the crucial links in modern urban life. In the process of sewage treatment, accurately measuring the sewage flow is the foundation for ensuring the efficient operation of the treatment system. Therefore, the measurement of sewage flow has become an indispensable part of the sewage treatment process.

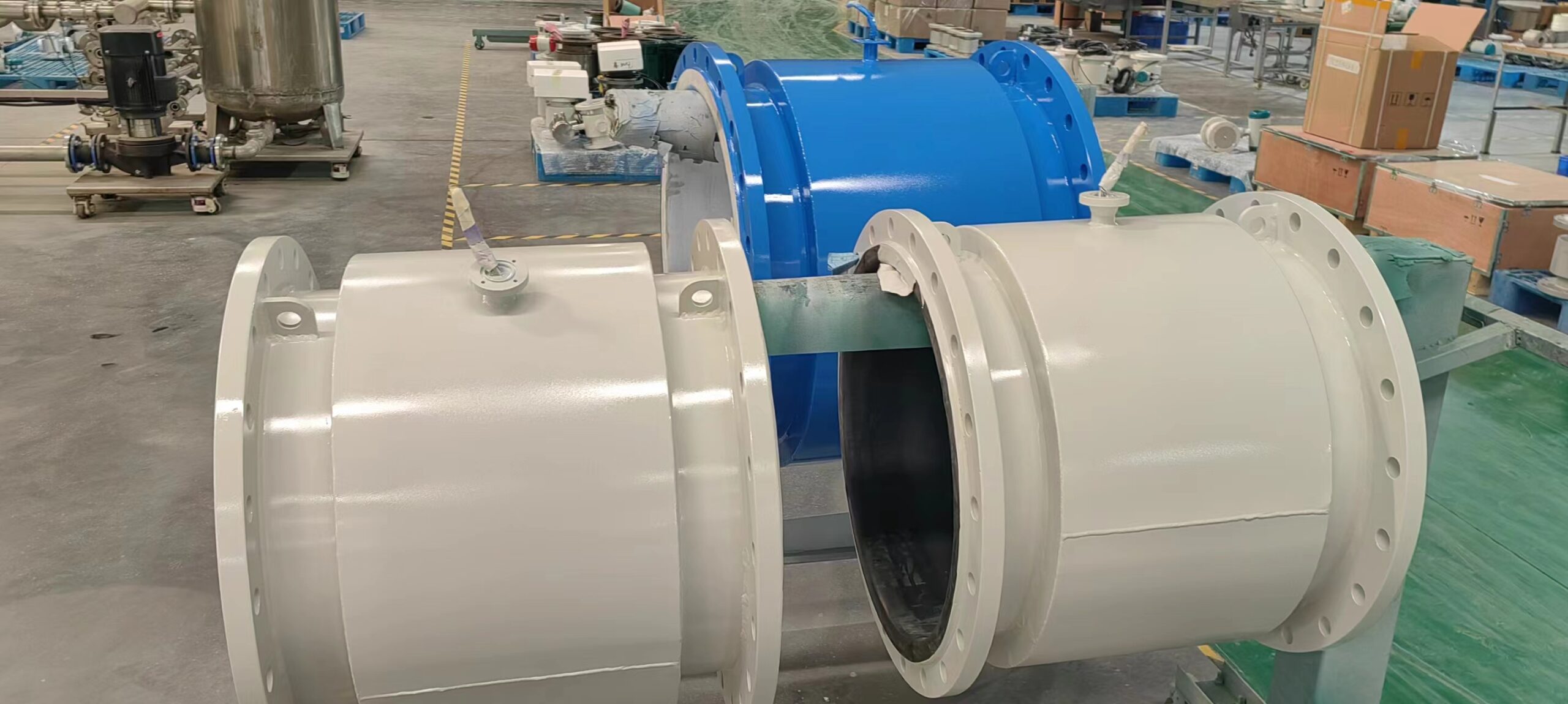

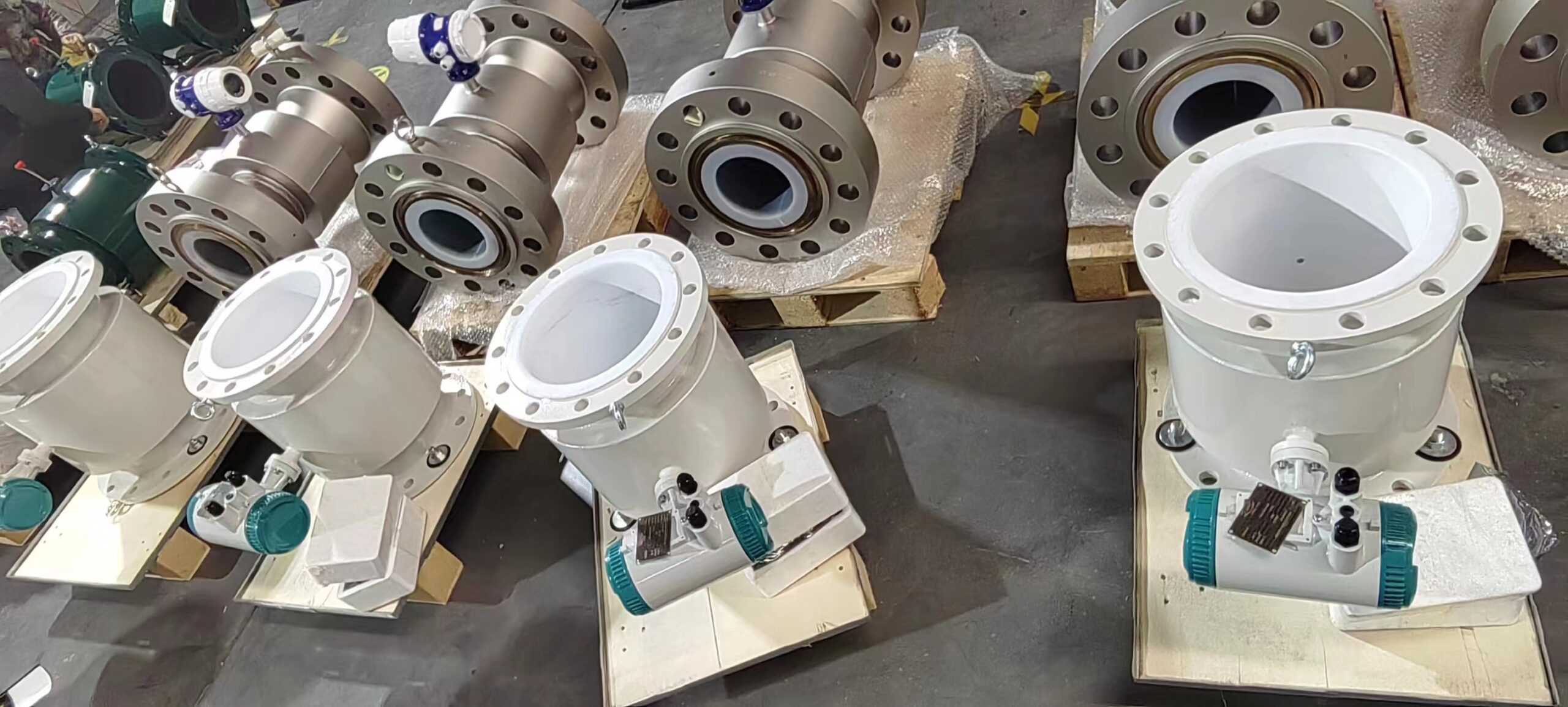

A sewage flowmeter was specially designed to measure the flow of sewage. A sewage flowmeter is a device capable of precisely measuring the flow of sewage. It can help operators understand the operation of the system and make necessary adjustments and optimizations to the treatment system.

When choosing a sewage flowmeter, some key factors need to be noted.

The material of the sewage flowmeter needs to have the characteristics of corrosion resistance and wear resistance to deal with various harmful substances existing in the sewage.

The accuracy and stability of the sewage flowmeter are also important indicators for evaluating its performance. Precise measurement results can provide accurate data, helping operators conduct comprehensive system management and decision-making.

3. A reliable sewage flowmeter also needs to have certain self-check and self-calibration functions to automatically calibrate and control the quality of the sensor, thereby ensuring the accuracy and credibility of the measurement results.

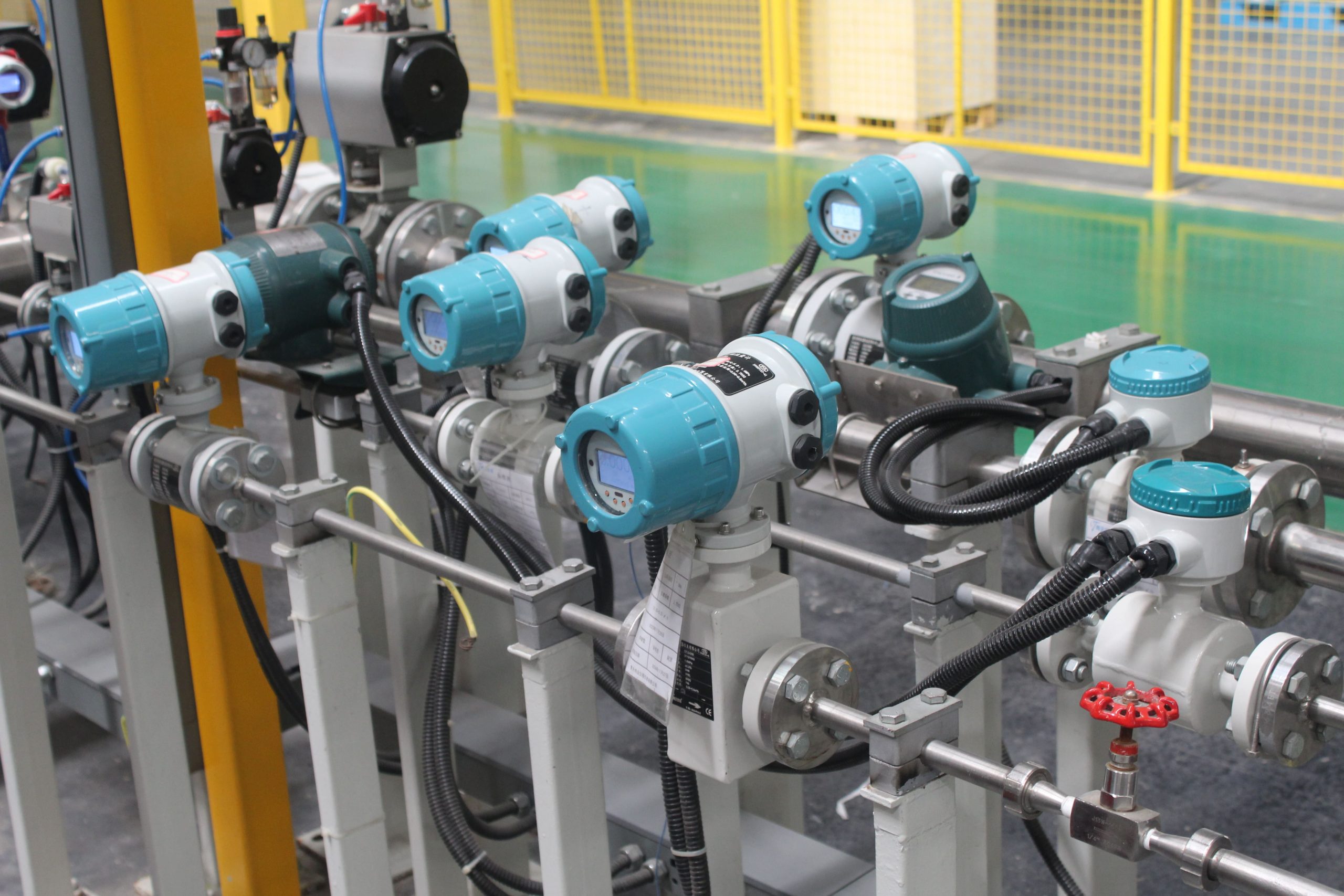

The common sewage flowmeters currently available in the market include electromagnetic flowmeters, ultrasonic flowmeters and vortex flowmeters, etc. Each type of flowmeter has its own advantages and characteristics and is suitable for different sewage treatment scenarios.

An electromagnetic flowmeter is a type of flowmeter that indirectly deduces the flow rate of a liquid by measuring the voltage generated by the induced electromotive force in the liquid. Because it is not affected by pipeline changes and sewage loads, it has good stability and reliability. The ultrasonic flowmeter calculates the flow velocity by sending ultrasonic pulses and measuring their propagation time, and then obtains the flow data. Ultrasonic flowmeters feature no pressure loss and no jamming, and are suitable for most environments and liquid media. Vortex flowmeters measure flow by utilizing the principle that the frequency of the vortices generated by the vortices is proportional to the flow rate. It is not affected by the electrical conductivity, temperature and pressure of the liquid and can adapt to harsh working environments.

No matter what type of sewage flowmeter it is, strict calibration and testing are required before use to ensure the accuracy and reliability of the measurement. The calibration process may include fixed-point measurement, comparison verification and online calibration, etc., to ensure that the flowmeter can meet the expected measurement requirements.

In addition to choosing the appropriate sewage flowmeter, it is also necessary to pay attention to the installation position and method of the flowmeter. Generally speaking, the flowmeter should be installed on the vertical section of the sewage pipe to avoid the influence of bubbles and impurities. Meanwhile, the installation position of the flowmeter also needs to be adjusted according to the specific processing system to ensure measurement accuracy and stability.