DN3-DN800 Battery-Powered Magnetic Flow Meter Digital Water Electromagnetic Flowmeter

Once the installation location is determined, the next step is preparing the piping system. Ensure that the pipeline is clean and free from debris that could interfere with the operation of the flowmeter. In some cases, straight pipe runs are recommended both upstream and downstream of the flowmeter to allow for proper fluid flow development and stabilization. This helps in achieving optimal measurement accuracy.

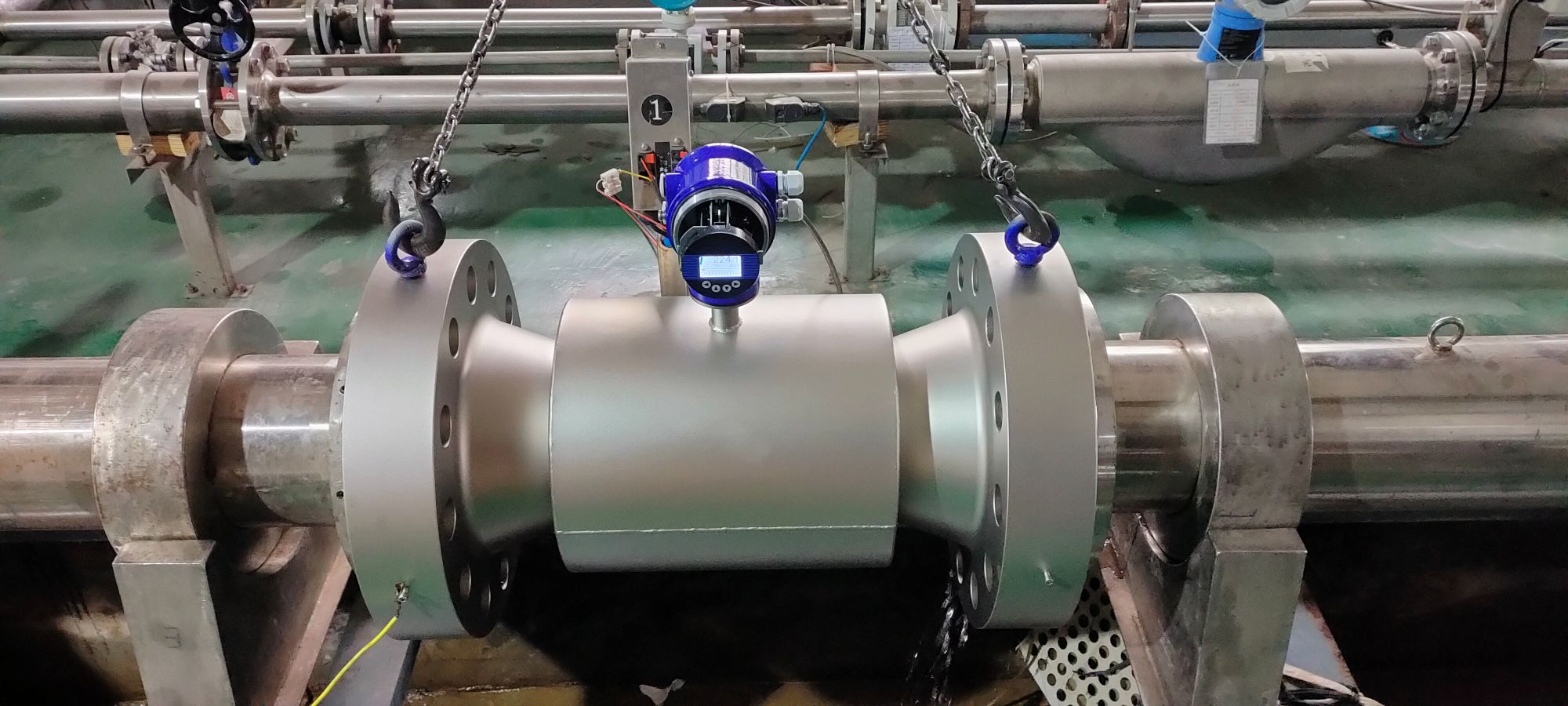

The electromagnetic flowmeter should be installed with the flow direction aligned with the arrow on the flowmeter body. Proper orientation ensures that the magnetic field generated by the flowmeter’s coils is perpendicular to the fluid flow, allowing for accurate measurements. Additionally, it is essential to properly ground the flowmeter to minimize electrical noise and interference, ensuring the stability of the measurement signals.

The installation process involves securely mounting the flowmeter on the piping system using appropriate brackets or supports. Care should be taken to align the flowmeter properly and tighten all connections to prevent leaks. Adequate sealing measures must be implemented to prevent ingress of moisture or contaminants into the flowmeter, which could adversely affect its performance.

-.jpg)