Do not know how to install all kinds of ultrasonic flowmeters?

Ultrasonic flowmeter in view of different installation methods, then the requirements for installation are also different, today the flowmeter manufacturer Aister meter mainly for the installation requirements of different installation methods of ultrasonic flowmeter, for you to make the following explanation.

1. Observe whether the pipeline on the installation site meets the distance between the first 10D and the last 5D of the straight pipe section and 30D from the pump. (D is the inner diameter of the pipe)

2, confirm the fluid medium in the pipeline and whether the pipe is full.

3. Confirm the material and wall thickness of the pipeline (fully considering the scaling thickness of the inner wall of the pipeline)

4, confirm the service life of the pipeline, in the use of about 10 pipes, even if it is carbon steel material, ** also use plug-in installation.

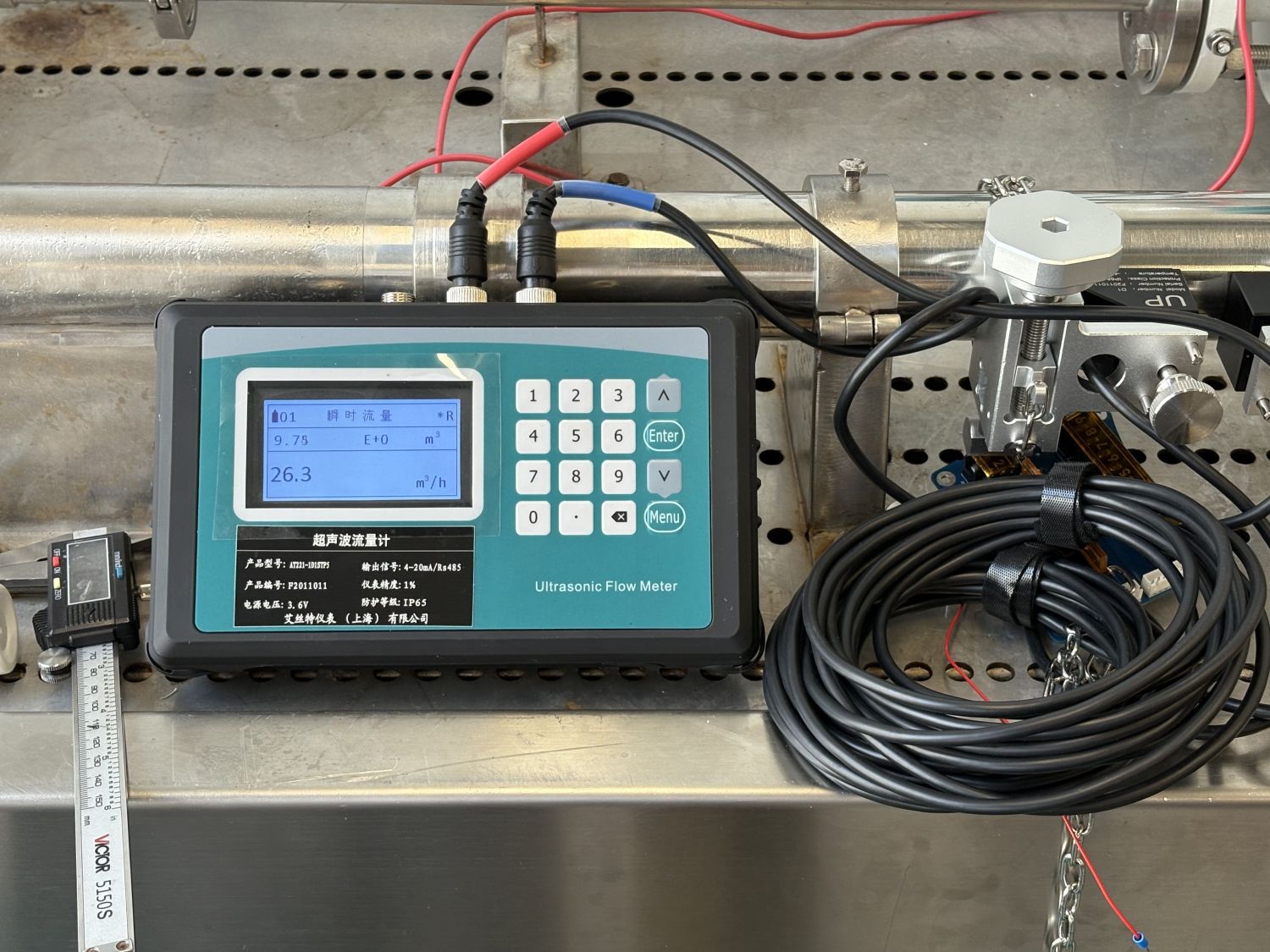

5. After the first four steps are completed, you can confirm which sensor is used for installation.

6, start to enter parameters into the table body to determine the installation distance.

7, very important: accurately measure the installation distance.

8, the external clamp optional installation sensor approximate distance, and then constantly debug the active sensor to achieve the signal and transmission ratio, better match.

9, insert the use of special tools to measure the distance of the installation point on the pipeline, this distance is very important, it directly affects the actual measurement accuracy of the table, so it is better to carry out multiple measurements in order to achieve higher precision.