What conditions should be met before installing an electromagnetic flowmeter

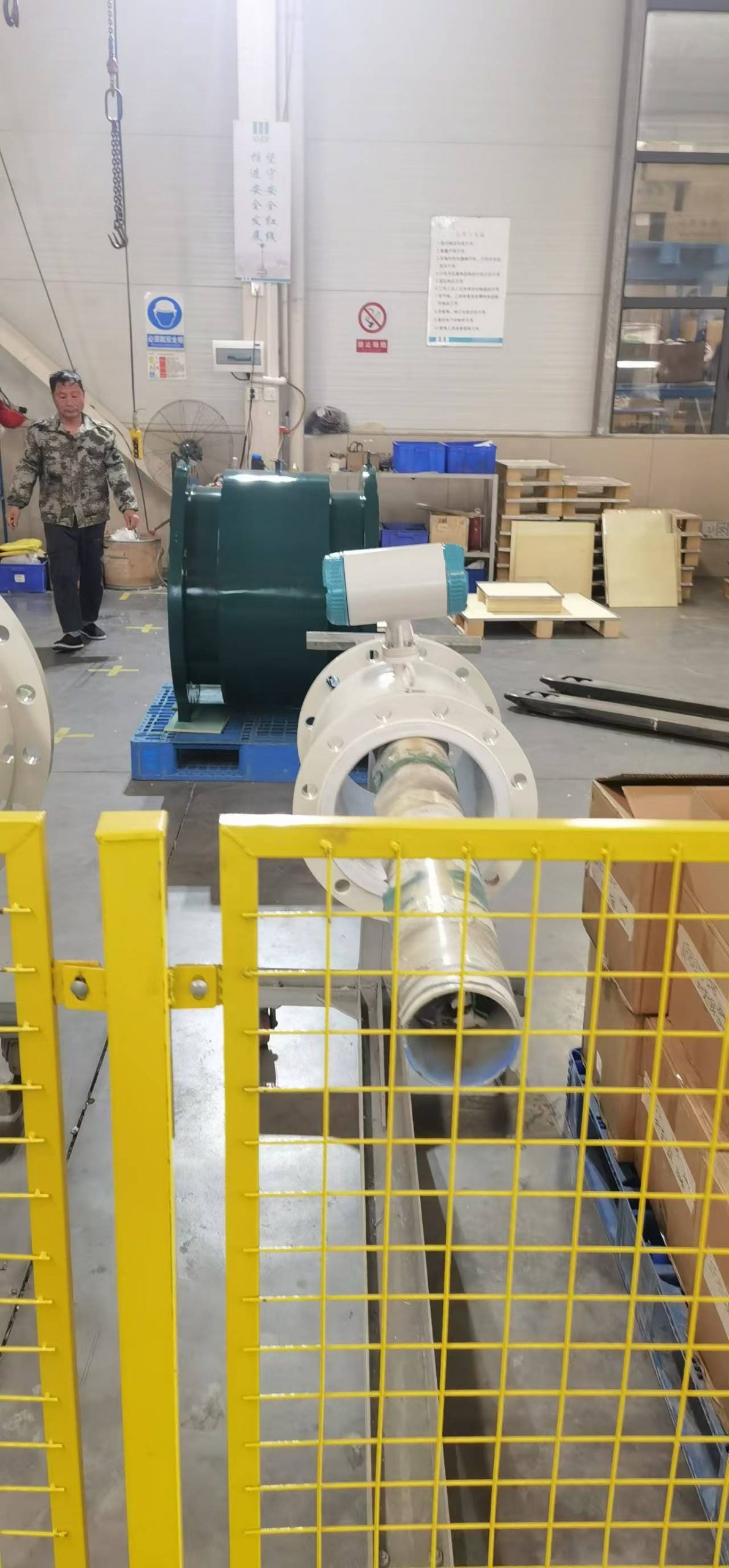

Pipe diameter and pipe vibration

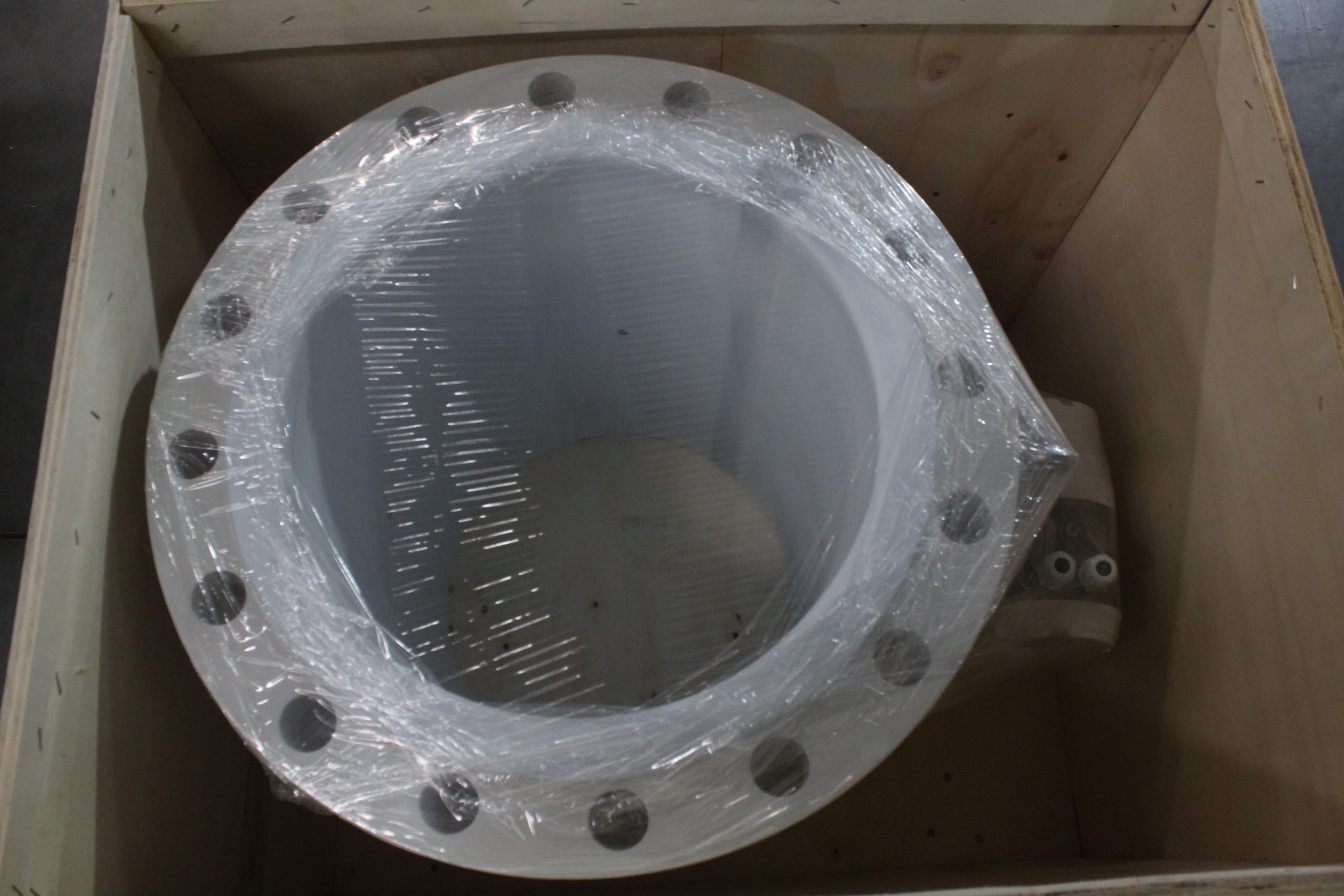

The pipe diameter range of some types of flowmeters is not very wide. Therefore, if it is too large or too small, it will limit the selection of flowmeter varieties. To measure low or high flow rates, a flowmeter pipe diameter different from the pipe diameter size can be selected.

Pipe diameter and pipe vibration

The pipe diameter range of some types of flowmeters is not very wide. Therefore, if it is too large or too small, it will limit the selection of flowmeter varieties. To measure low or high flow rates, a flowmeter pipe diameter different from the pipe diameter size can be selected. A reducer pipe can be used for connection to ensure that the flowmeter operates within the specified range. If the flow rate exceeds the range or the flow velocity is too low, the error of the flowmeter will increase and it will fail to work. If the flow velocity is too high, the error of the flowmeter may also increase. At the same time, it may cause the flow sensor to be too fast or the pressure drop to be too large, which may damage the use of the flowmeter.

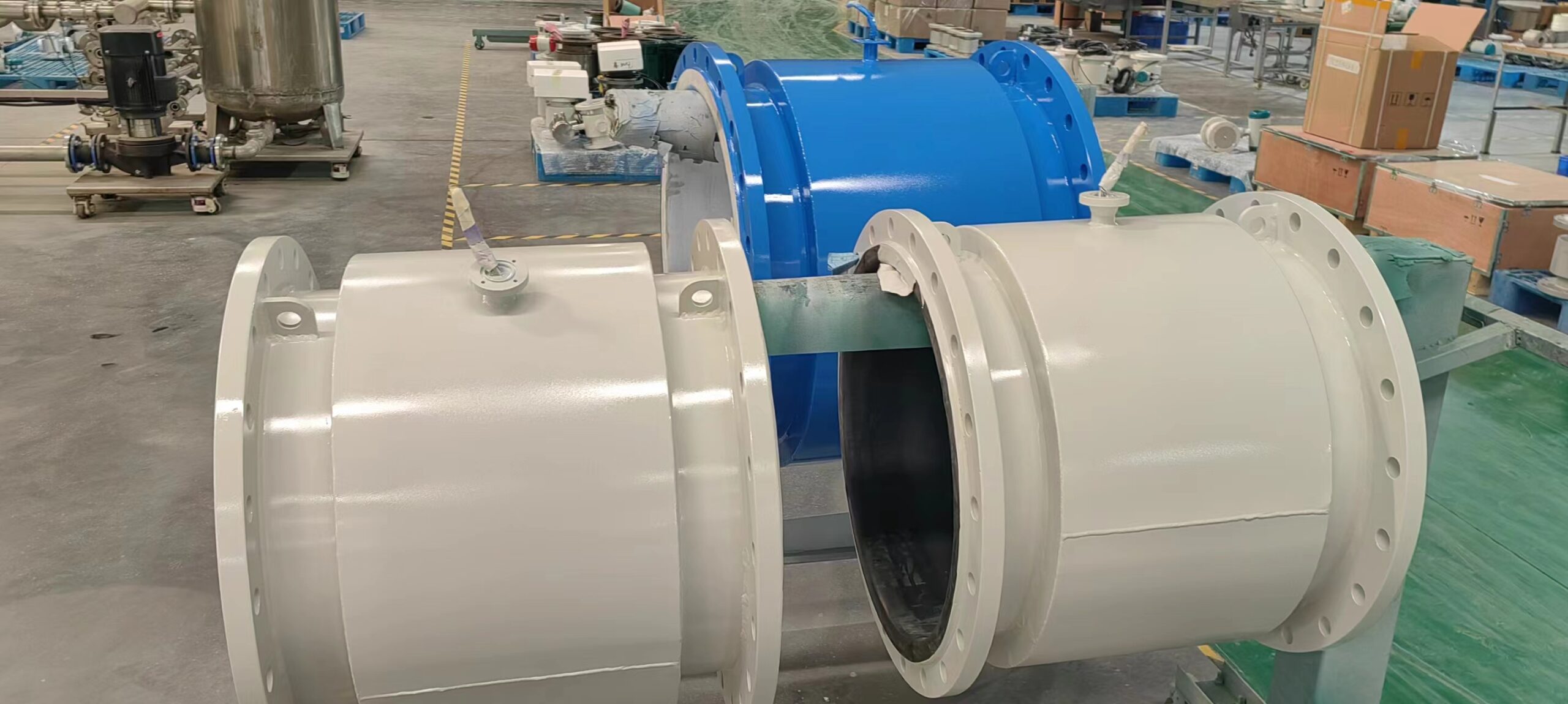

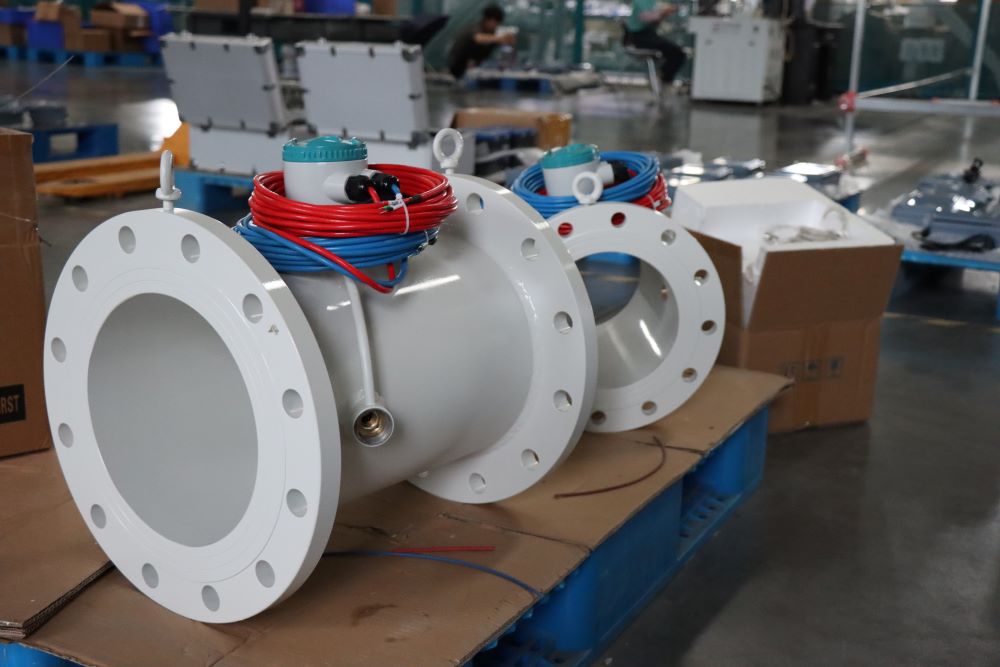

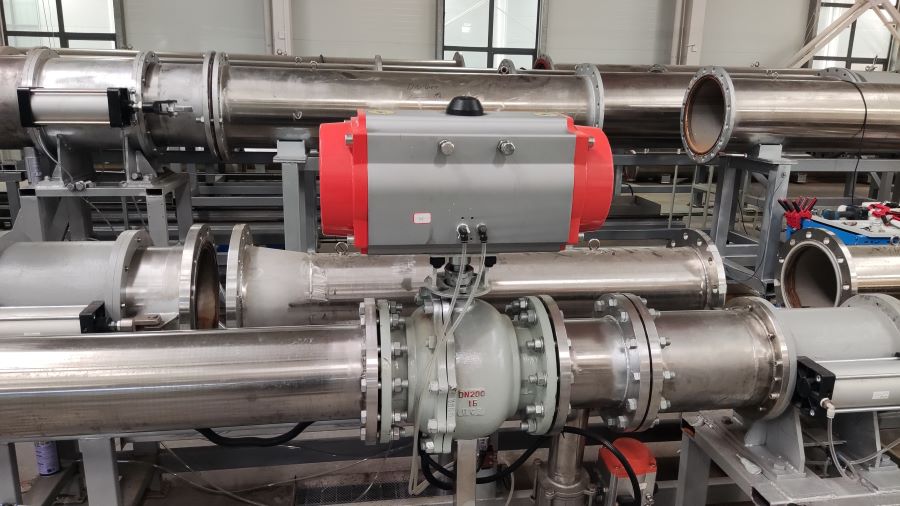

2. The installation position of the valve

Control valves and isolation valves are installed on the pipelines where flowmeters are installed. To prevent some flow velocity distribution disturbances and cavitation caused by the valves from affecting the flowmeter measurement, the control valves are generally installed downstream of the flowmeter. Installing the control valves downstream of the flowmeter can also increase the back pressure of the flowmeter, which is conducive to reducing the possibility of cavitation generation inside the flowmeter.

The purpose of installing the isolation valve is to separate the flowmeter from the fluid in the pipeline for easy maintenance. The upstream valve should be at a sufficient distance from the flowmeter. When the flowmeter is in operation, the upstream valve should be fully open to avoid disturbances such as distortion of the flow velocity distribution.

3. Protective accessories

Installing protective accessories is a protective measure to ensure the normal operation of the flowmeter. For instance, in volumetric flowmeters and turbine flowmeters, it is generally necessary to install some essential equipment such as filters upstream. The installation of all these devices should ensure that they do not affect the use of the flowmeter.

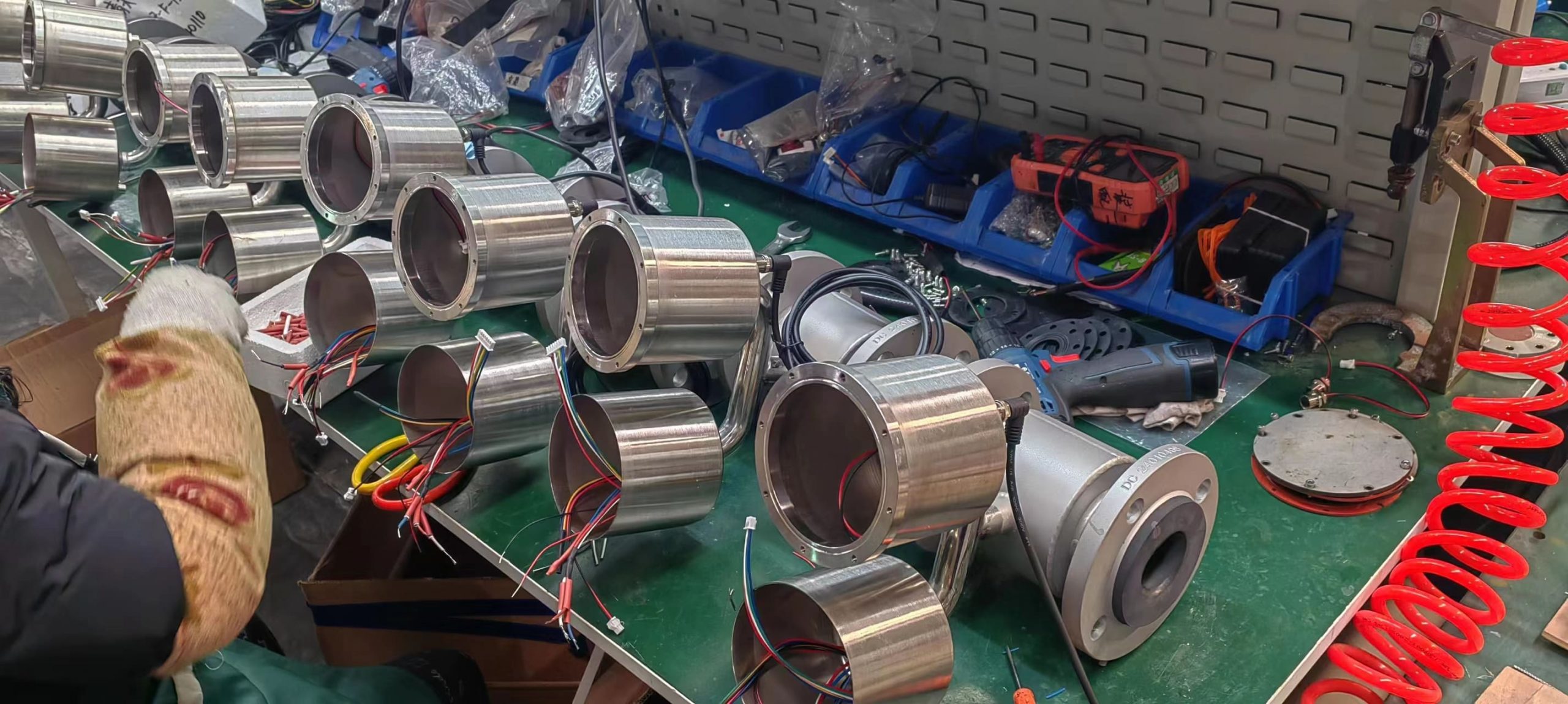

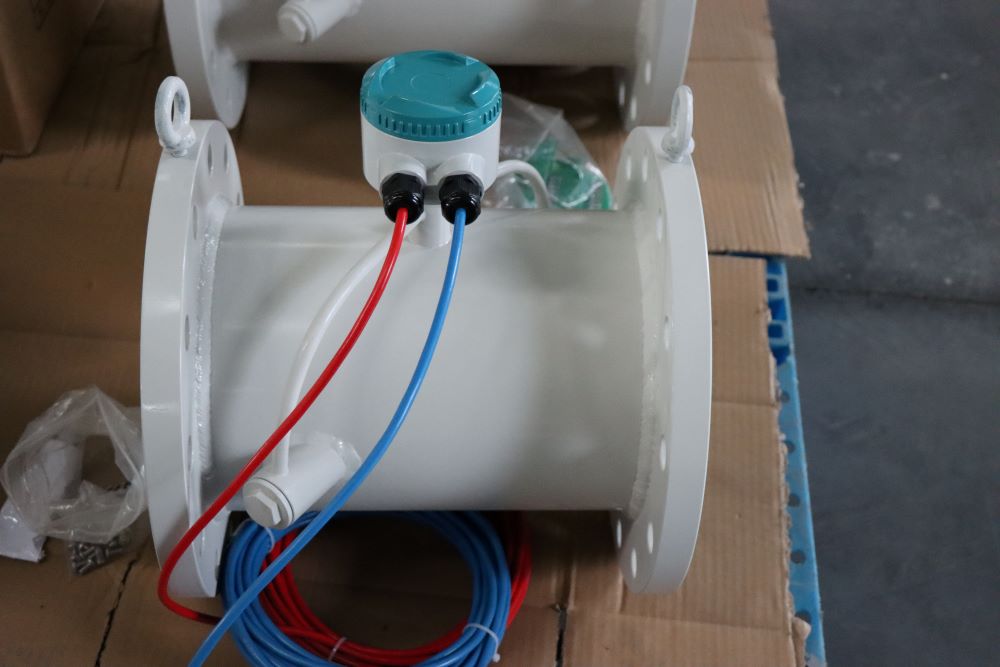

4. Electrical connection and electromagnetic interference

At present, most flow measurement systems, whether it is the flowmeter itself or its accessory connections, all have electronic devices. Therefore, the power supply adopted should be compatible with the flowmeter. When the output level of the flowmeter is low, a preamplifier that is suitable for the environment should be used. The output signals of some types of flowmeters are prone to interference from high-power switching devices, causing fluctuations in the output pulses of the flowmeter and affecting its performance. For instance, signal cables should be kept as far away as possible from power cables and power sources to reduce the impact of electromagnetic interference and radio frequency interference.

-.jpg)