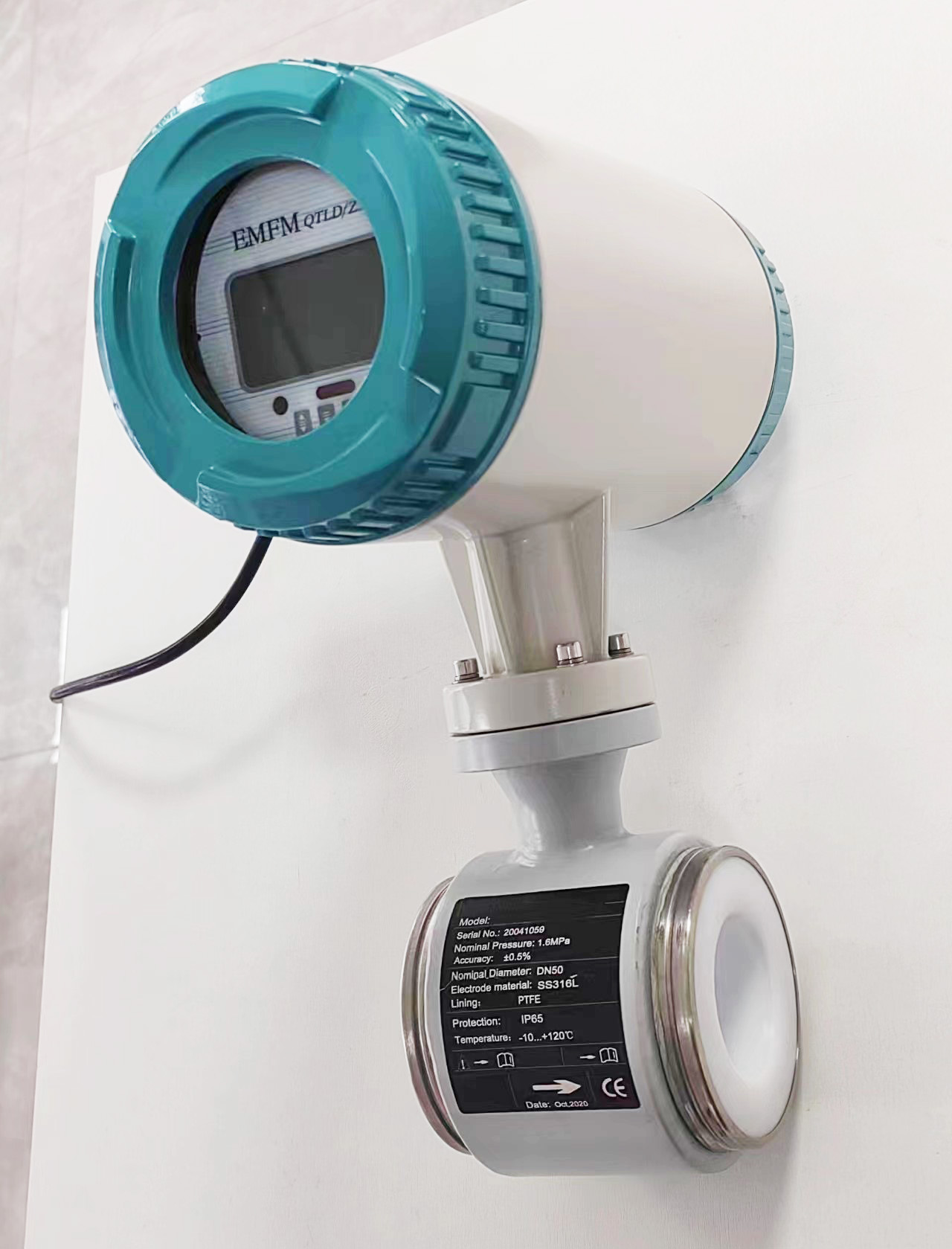

Domestic sewage flowmeter site installation points

The sewage flowmeter has a wide range of applications and is favored by the owner, but the application performance of the sewage flowmeter has a great relationship with the installation on site. Aister makes the following requirements for the installation points of the sewage flowmeter:

Sewage flowmeter installation site

1, when measuring mixed phase fluid, choose a place that will not cause phase separation; When measuring two-component liquids, avoid loading downstream where the mixture has not been uniform; When measuring the chemical reaction pipe, it should be installed downstream of the reaction fully completed section;

2, as far as possible to avoid the measurement tube will become negative pressure;

3, choose a place with small vibration, especially for a body type instrument;

4, avoid nearby motors, large transformers, etc., so as not to cause electromagnetic field interference;

5, easy to achieve separate grounding of the sensor;

6, as far as possible to avoid the surrounding environment with high concentration of corrosive gases;

7. Avoid direct sunlight as much as possible;

8, avoid rain immersion, will not be submerged by water (except protection level IP68).