To ensure the operation of the electromagnetic flowmeter, the following points must not be ignored

The measurement principle of the electromagnetic flowmeter is Faraday’s law of electromagnetic induction. It is an instrument that measures the flow of conductive fluids based on the induced electromotive force when the conductive fluid passes through an external magnetic field.

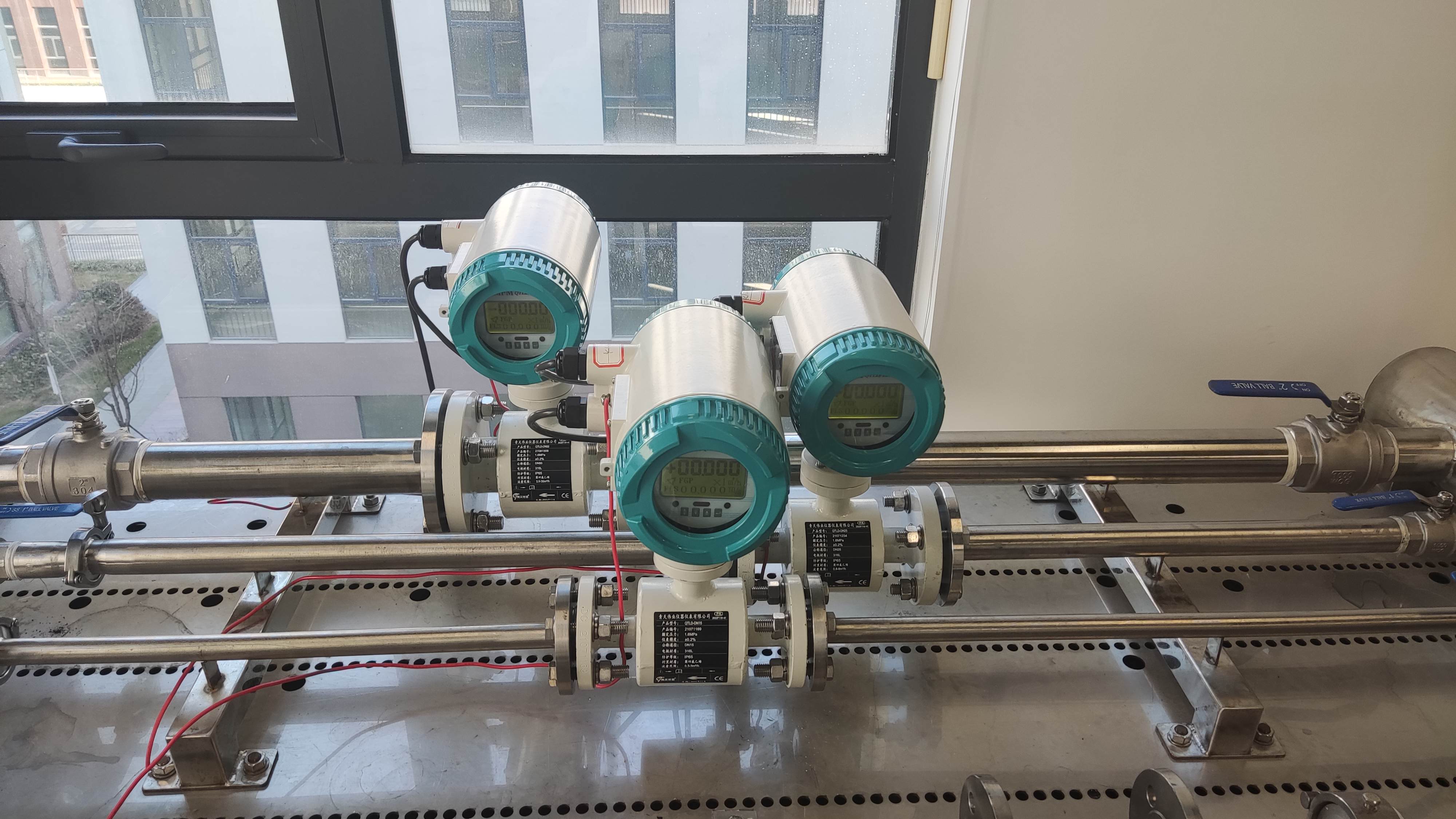

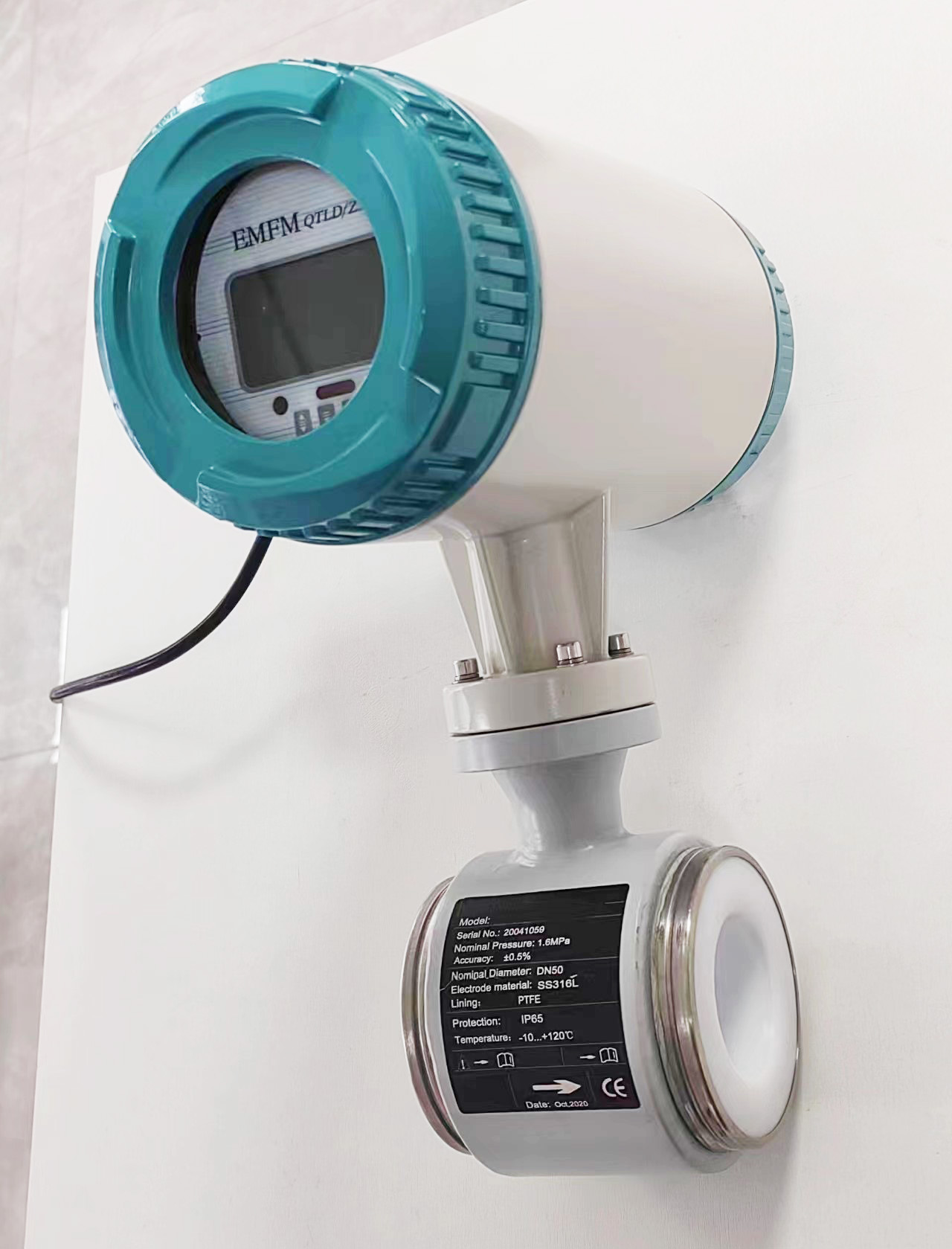

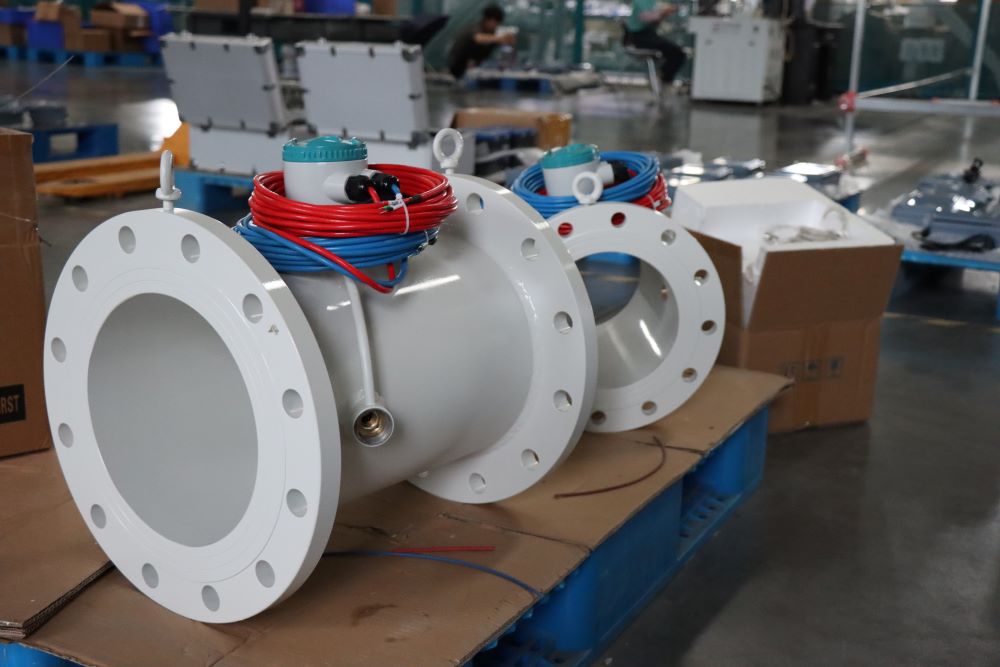

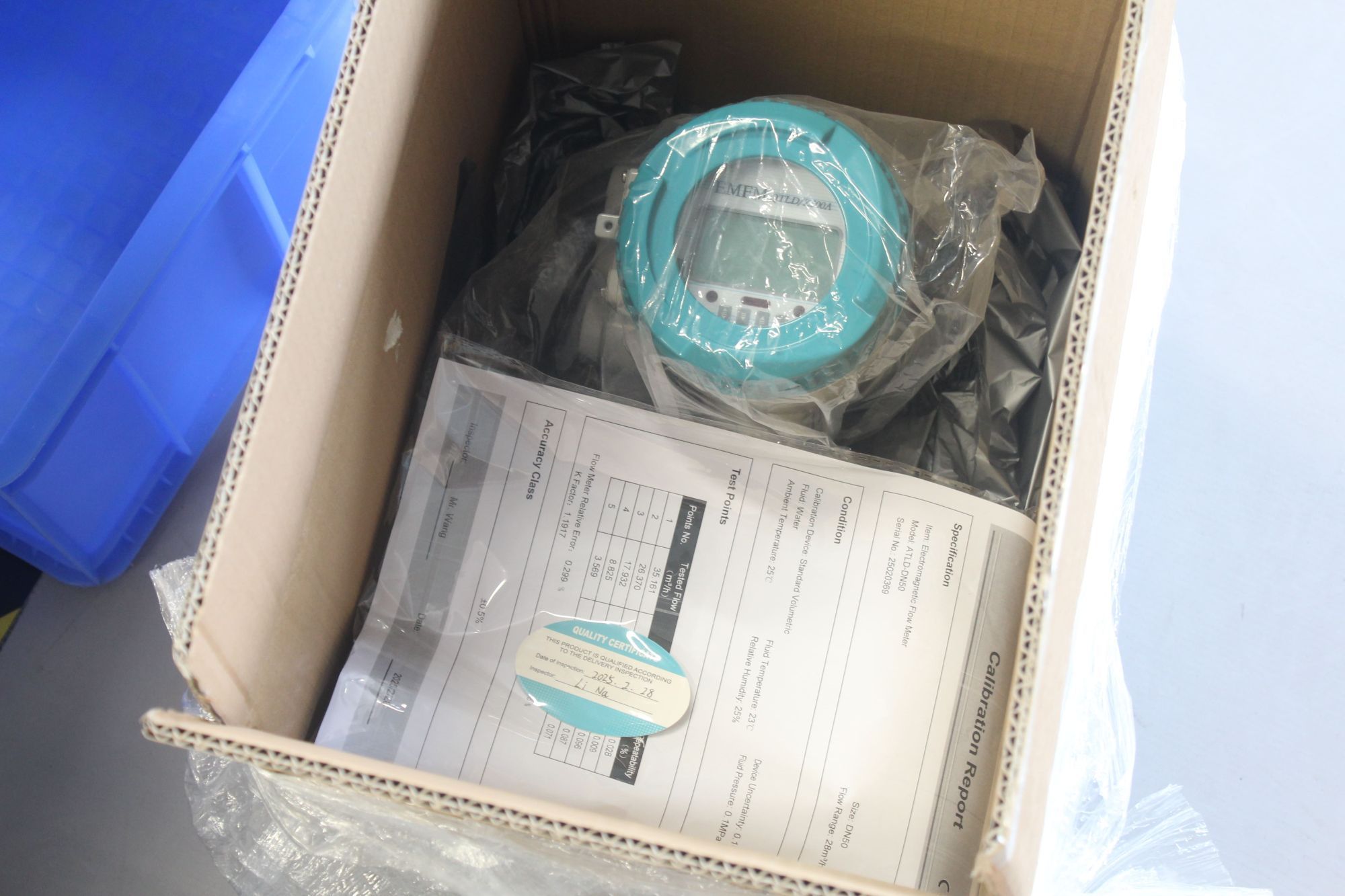

The measurement principle of the electromagnetic flowmeter is Faraday’s law of electromagnetic induction. It is an instrument that measures the flow of conductive fluids based on the induced electromotive force when the conductive fluid passes through an external magnetic field. The main components of the sensor are: measuring tube, electrodes, excitation coil, iron core and magnetic yoke housing. The product is mainly used to measure the volume flow of conductive liquids and slurries in closed pipelines, including strongly corrosive liquids such as acids, alkalis and salts.

What are the requirements that must not be ignored for the efficient operation of electromagnetic flowmeters?

When measuring mixed liquids, it should be installed in a factory where the mixed liquids will not separate.

When measuring two-component liquids, avoid installing them downstream where the mixture is uneven.

3. When measuring chemical liquids, it should be installed downstream where the reaction is complete.

4. Try to avoid negative pressure in the pipeline.

5. Try to install it on pipes with less vibration.

6. Try to avoid large electromechanical equipment near the intelligent electromagnetic flowmeter to prevent electromagnetic interference.

7. Try to install the sensor in a factory that is convenient for grounding.

8. Try to avoid the presence of highly corrosive gases around the intelligent electromagnetic flowmeter.

9. The humidity of the installation environment should be controlled within the range of 10% to 90% as much as possible.

10. Try to avoid long-term direct exposure to sunlight.

11. Avoid being exposed to rain and take good waterproof measures.

-.jpg)