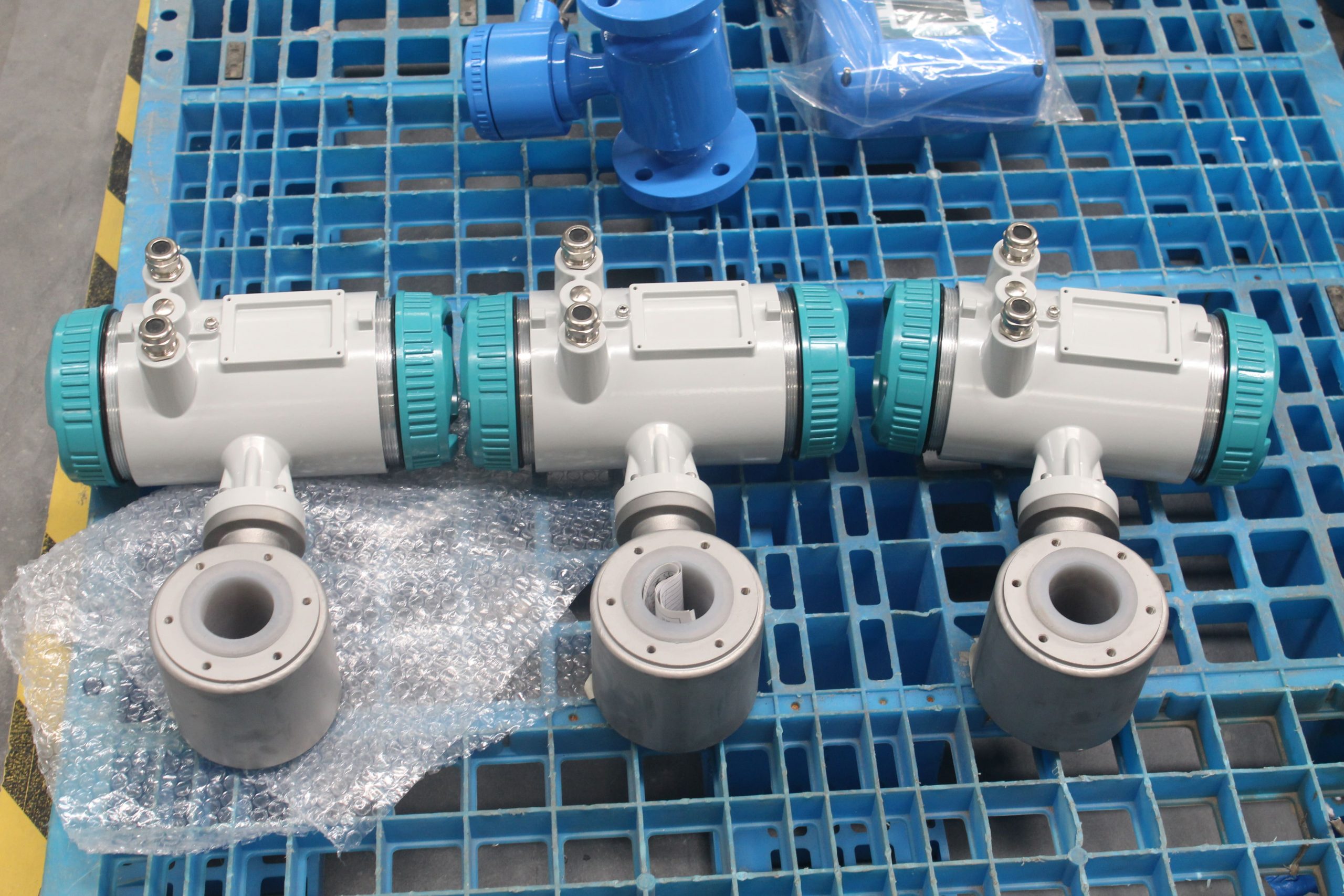

Selection and installation points of split-type intelligent electromagnetic flowmeters

Improper selection and installation of split-type intelligent electromagnetic flowmeters can affect the accuracy of the flowmeter’s use and even damage the service life of the instrument. Today, the editor of Aister Instrument, a flowmeter manufacturer, will make the following discussion on the key points to note when installing split-type intelligent electromagnetic flowmeters.

When choosing a split-type intelligent electromagnetic flowmeter, it is advisable to avoid operating at the lower limit value as much as possible. Therefore, the diameter of the flowmeter should be as small as possible to obtain a larger flow velocity and flow range.

2. Flowmeters are applied in the technical parameters of the working pressure and temperature range of the medium. Do not deliberately choose high-pressure grade and ultra-high-temperature instruments. Instruments should be selected based on the actual working pressure and temperature, as the latter is more expensive.

3. In explosion-hazardous areas, explosion-proof split-type intelligent electromagnetic flowmeters should be selected.

The lower limit flow rate of the split-type intelligent electromagnetic flowmeter depends on the working condition density and kinematic viscosity of the medium. The upper limit flow rate is generally not affected by the medium pressure and temperature. So, as long as the actual available lower limit flow rate is determined, the flow range can be determined. After calculating the lower limit flow rate, check the flow range table to determine the corresponding diameter.

Six major requirements for the installation environment of split-type intelligent electromagnetic flowmeters

Try to avoid strong electrical equipment, high-frequency equipment and strong switching power supply equipment. The power supply of the flowmeter should be separated from these devices as much as possible.

2. Avoid direct influence from high-temperature heat sources and radiation sources. If installation is necessary, heat insulation and ventilation measures must be taken.

3. Avoid high-humidity environments and environments with strong corrosive gases. If installation is necessary, ventilation measures must be taken.

4. Split-type intelligent electromagnetic flowmeters should be avoided from being installed on pipelines with strong vibration as much as possible. If installation is required, pipe fastening devices should be added at 2D upstream and downstream, and anti-vibration pads should be added to enhance the anti-vibration effect.

5. The instrument should be installed indoors. If it is installed outdoors, waterproofing should be noted. Special attention should be paid to bending the cable into a U shape to prevent water from entering the amplification shell along the cable.

6. There should be sufficient space for installation wiring and regular maintenance around the instrument installation point.

The installation position of the split-type intelligent electromagnetic flowmeter must ensure that the pipe is always full. The installation position of the split-type intelligent electromagnetic flowmeter should be far away from high-power motors, and the split-type intelligent electromagnetic flowmeter should be properly grounded.

-.jpg)

-.jpg)