Can electromagnetic flowmeters measure mud

Electromagnetic flowmeters can measure mud. The electromagnetic flowmeter utilizes the principle of Faraday’s law of electromagnetic induction. It calculates the flow rate by measuring the induced electromotive force generated when a conductive liquid flows in a magnetic field. It has the advantages of high precision, no mechanical wear, and bidirectional measurement. Mud, as a conductive liquid containing a large amount of solid particles, although it has high requirements for measuring equipment, electromagnetic flowmeters, due to their unique measurement principles and superior performance, have become the ideal choice for measuring mud flow.

Electromagnetic flowmeters can measure mud. The electromagnetic flowmeter utilizes the principle of Faraday’s law of electromagnetic induction. It calculates the flow rate by measuring the induced electromotive force generated when a conductive liquid flows in a magnetic field. It has the advantages of high precision, no mechanical wear, and bidirectional measurement. Mud, as a conductive liquid containing a large amount of solid particles, although it has high requirements for measuring equipment, electromagnetic flowmeters, due to their unique measurement principles and superior performance, have become the ideal choice for measuring mud flow.

The application of electromagnetic flowmeters in mud measurement has significant advantages:

1. High precision: The measurement accuracy of electromagnetic flowmeters is typically within ±0.5%, making them suitable for application scenarios that require high-precision measurement.

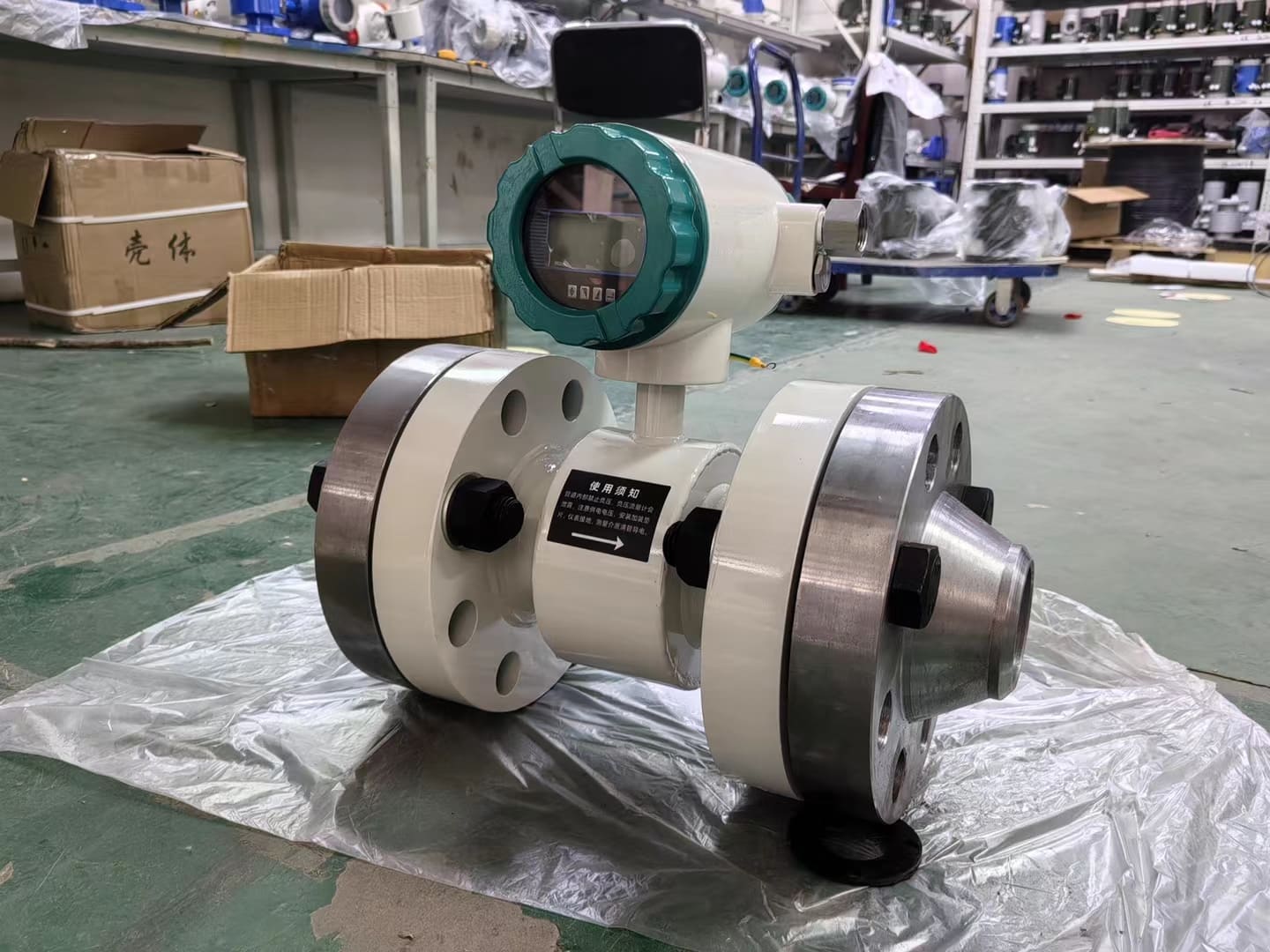

2. No mechanical wear: The electromagnetic flowmeter has no moving parts inside, so there is no problem of mechanical wear. It is suitable for measuring slurry containing solid particles.

3. Wear and corrosion resistance: The inner wall of the measuring tube of an electromagnetic flowmeter is usually made of wear-resistant and corrosion-resistant materials (such as rubber or polytetrafluoroethylene), which extends its service life.

4. Bidirectional measurement: Electromagnetic flowmeters can measure bidirectional flowing mud, making them convenient for use in complex process flows.

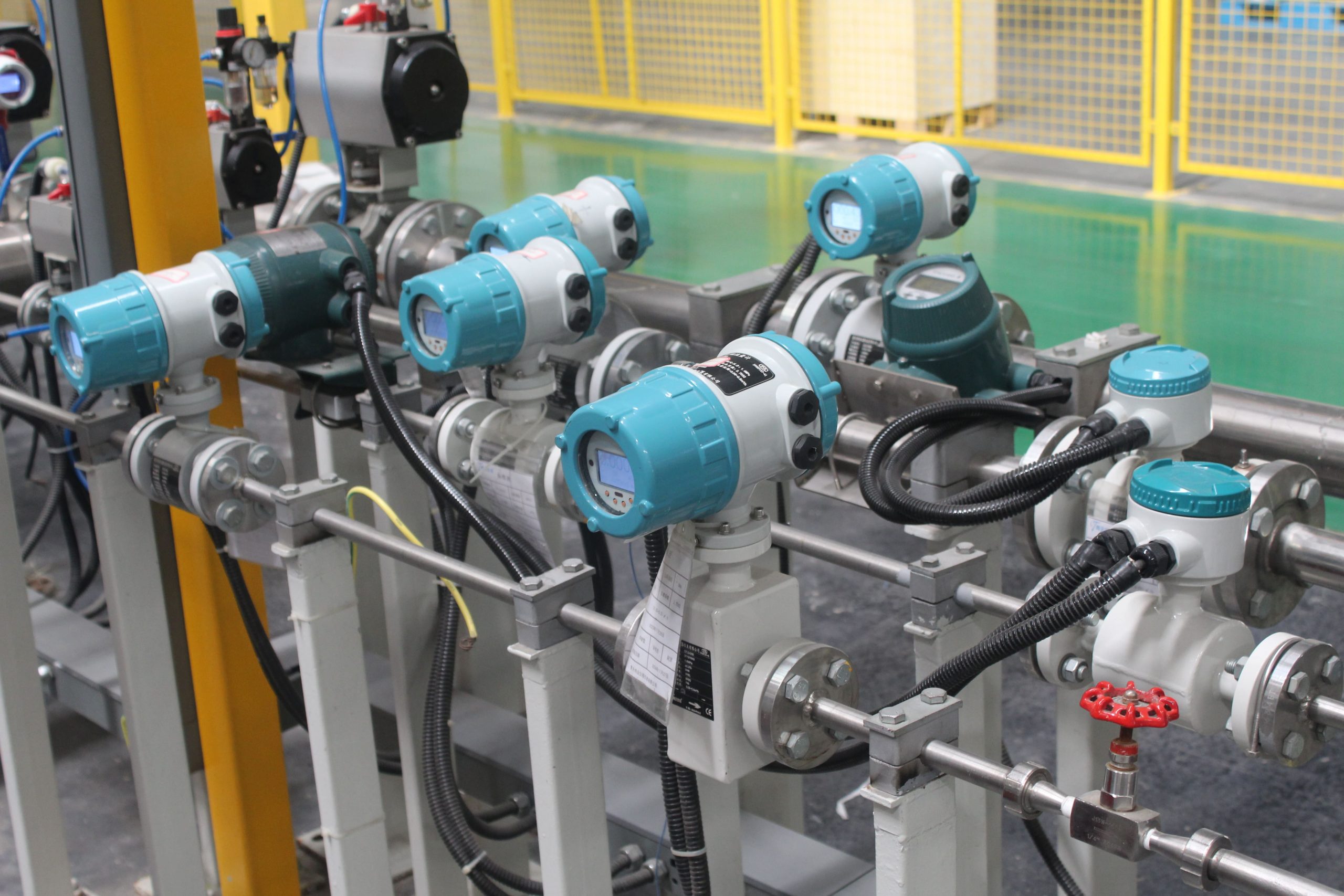

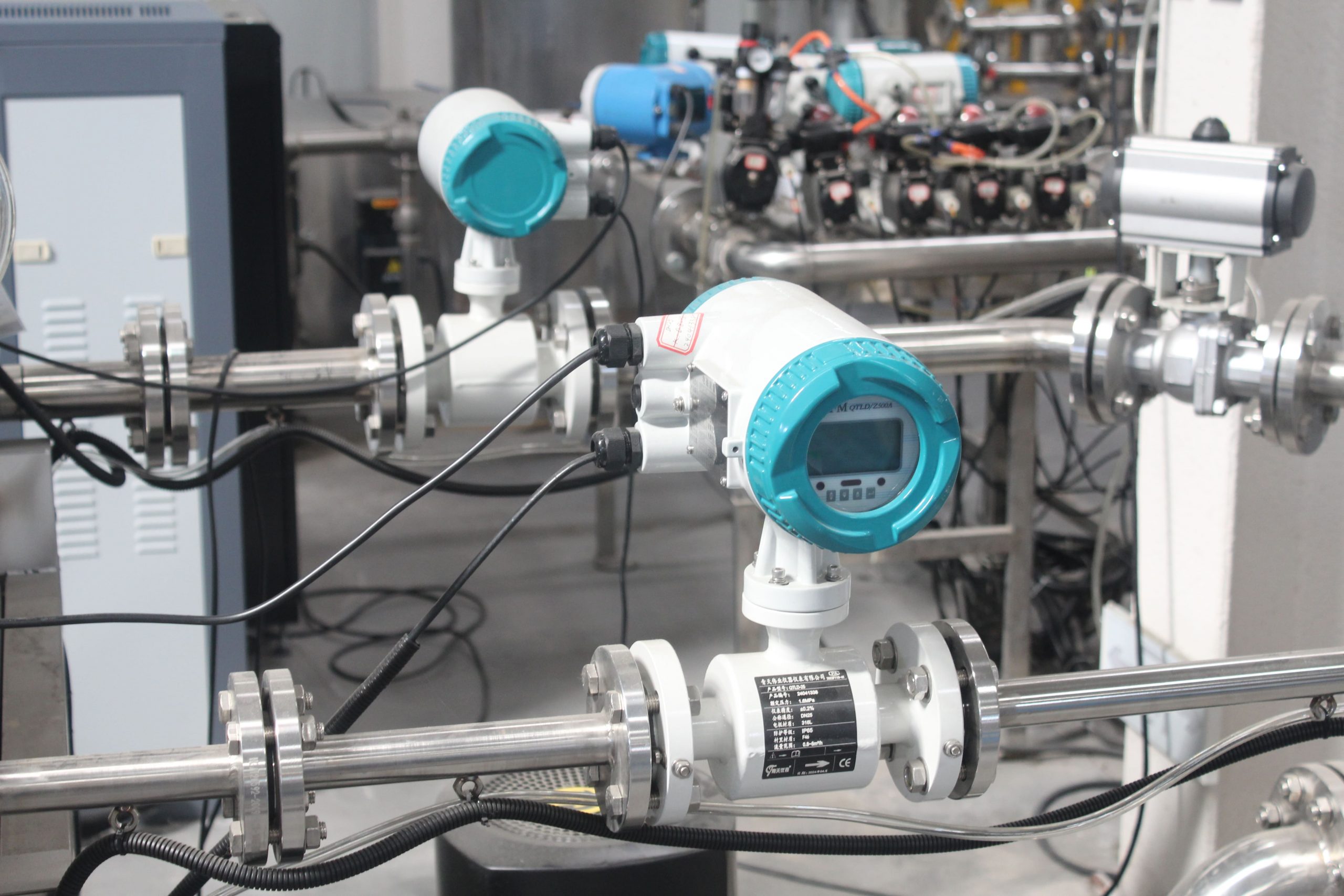

In mud measurement, electromagnetic flowmeters have a wide range of applications, including fields such as petroleum, mining, chemical engineering, and sewage treatment. For example, during the drilling process, electromagnetic flowmeters can be used to measure the flow of drilling fluid and mud, ensuring the safety and efficiency of the drilling process. In sewage treatment plants, electromagnetic flowmeters can be used to measure the flow of sludge containing a large amount of solid particles, helping to monitor and control the treatment process.

It should be noted that when choosing an electromagnetic flowmeter for mud measurement, it is necessary to ensure that the mud is conductive, as the working principle of the electromagnetic flowmeter relies on the flow of conductive liquids. In addition, the appropriate model and specification of the electromagnetic flowmeter should be selected based on specific measurement requirements and working conditions. During the installation and usage process, it is also necessary to follow the relevant installation requirements and operating procedures to ensure the accuracy and reliability of the measurement results.

-.jpg)

-.jpg)