Test methods for electromagnetic flowmeters and RS485 communication

The connection method between the electromagnetic flowmeter and RS485: Connect the TXD and RXD of the flowmeter to the RX+ and RX- of the RS485. If the connected wire is relatively long, a matching resistor of 100-200 ohms can be added at the remote end, and then plug the RS485 into the serial port of the microcomputer. After the connection is completed, how do we know that the connection is correct and no errors have occurred? Test method for 485 communication of electromagnetic flowmeter

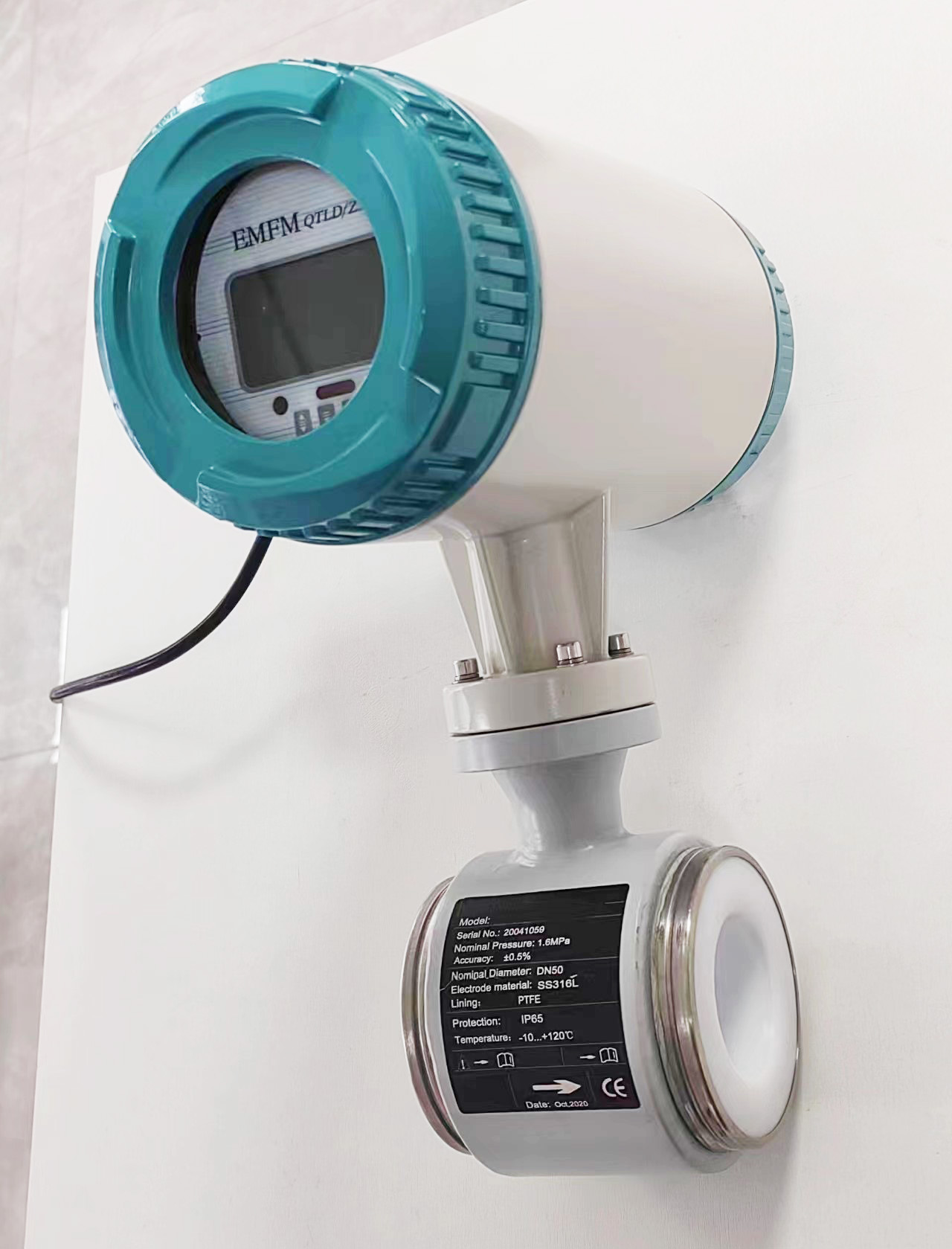

After connecting the wires, power on the electromagnetic flowmeter, enter the parameter setting screen, and set the communication speed and communication address of the flowmeter.

2. On the CD, you can see two folders named “WIN98” and “WINXP”. Select one of them based on the system your computer is using. There is a file named “SETUP” in the folders. Double-click it to enter the installation state, and then follow the prompts to operate.

After the installation is completed, in the “Programs” section of the Start menu, you can see a new program named L-mag(51) added. Clicking on it will open the communication test program.

4. Set the communication address, communication rate and communication port on the electromagnetic flowmeter software to be the same as those set on the electromagnetic flowmeter, and then click Start.

5. In this way, the corresponding data such as instantaneous flow rate and flow velocity will be displayed on the microcomputer. Click on the multi-machine communication in the communication mode menu above to enter the multi-machine display screen.

6. The software automatically searches for communication addresses. Clicking on the menu above will display the corresponding data of multiple electromagnetic flowmeters. When comparing the data on the microcomputer, it should be the same as that displayed by the electromagnetic flowmeters.