The function and method of electromagnetic flow meter grounding

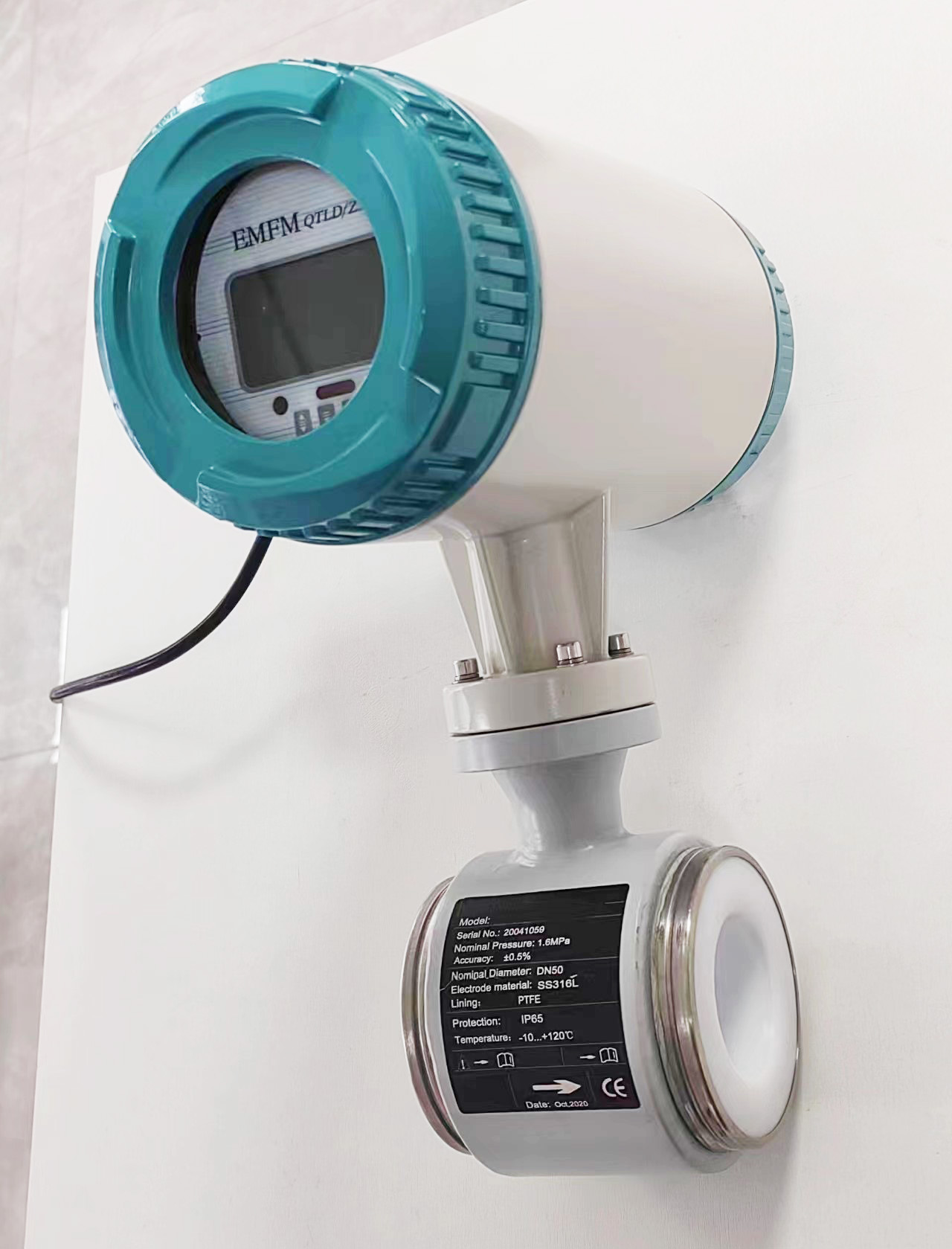

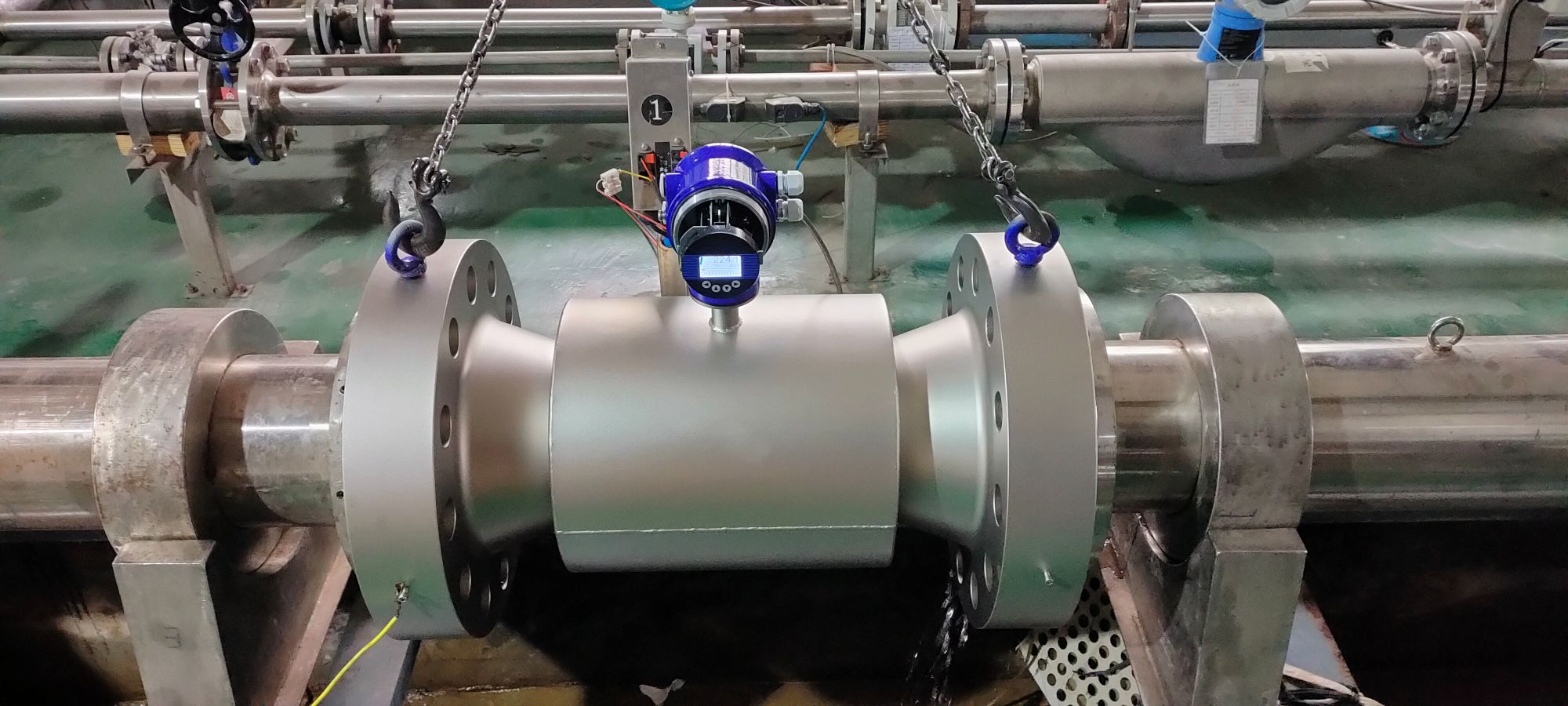

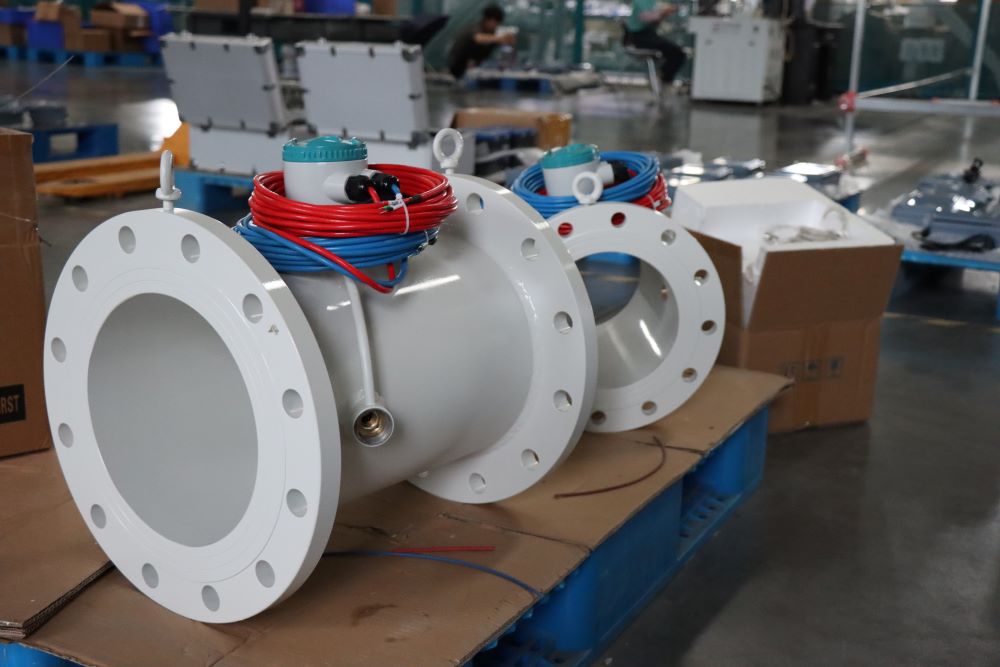

Electromagnetic flowmeter at work requires that the measured medium must be ground potential, generally through the pipeline or flange ground, if the process pipe connected to the sensor relative to the measured medium is insulated (plastic pipe or pipe with an insulating lining), you must choose a grounding ring or sensor with a grounding electrode, so that the measured medium in the ground potential, easy to be ignored in the actual design and installation.

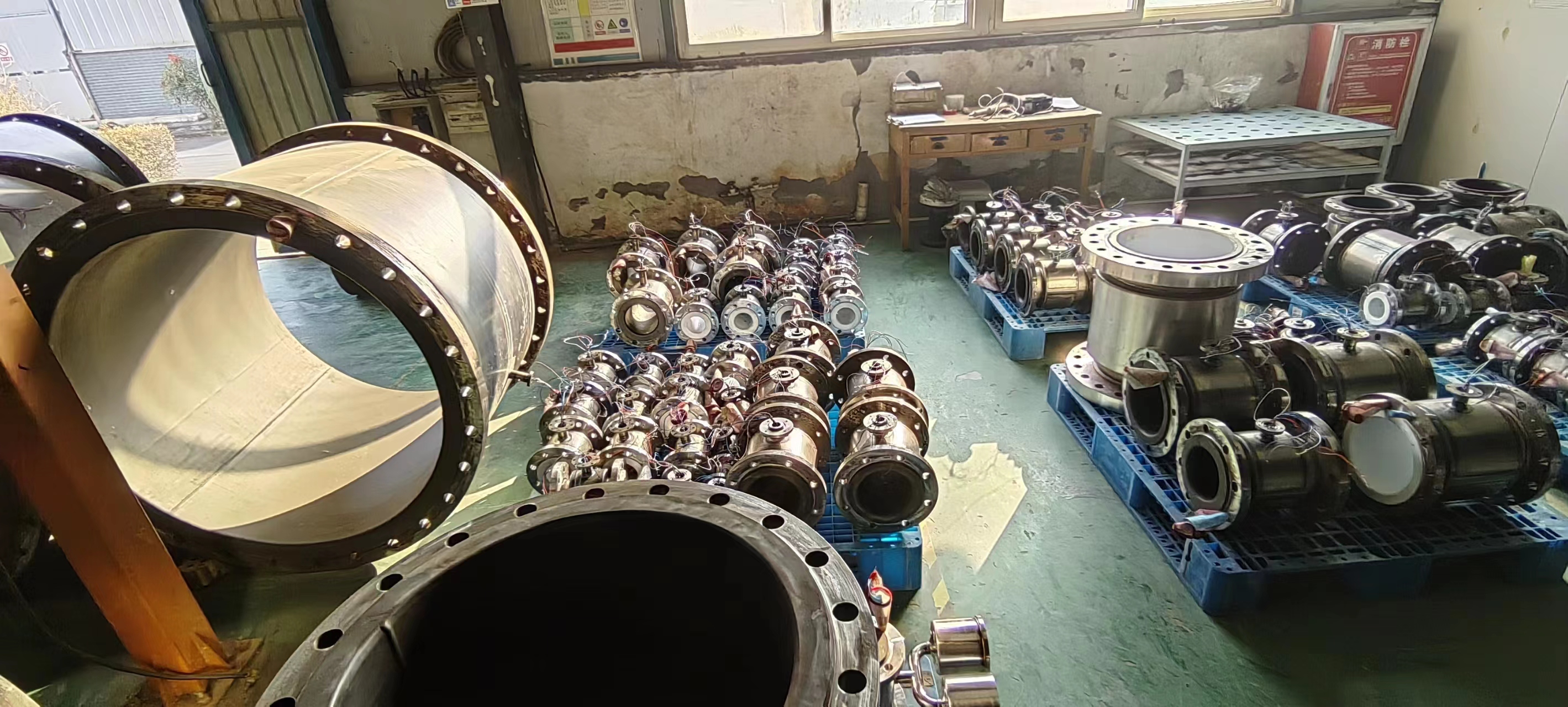

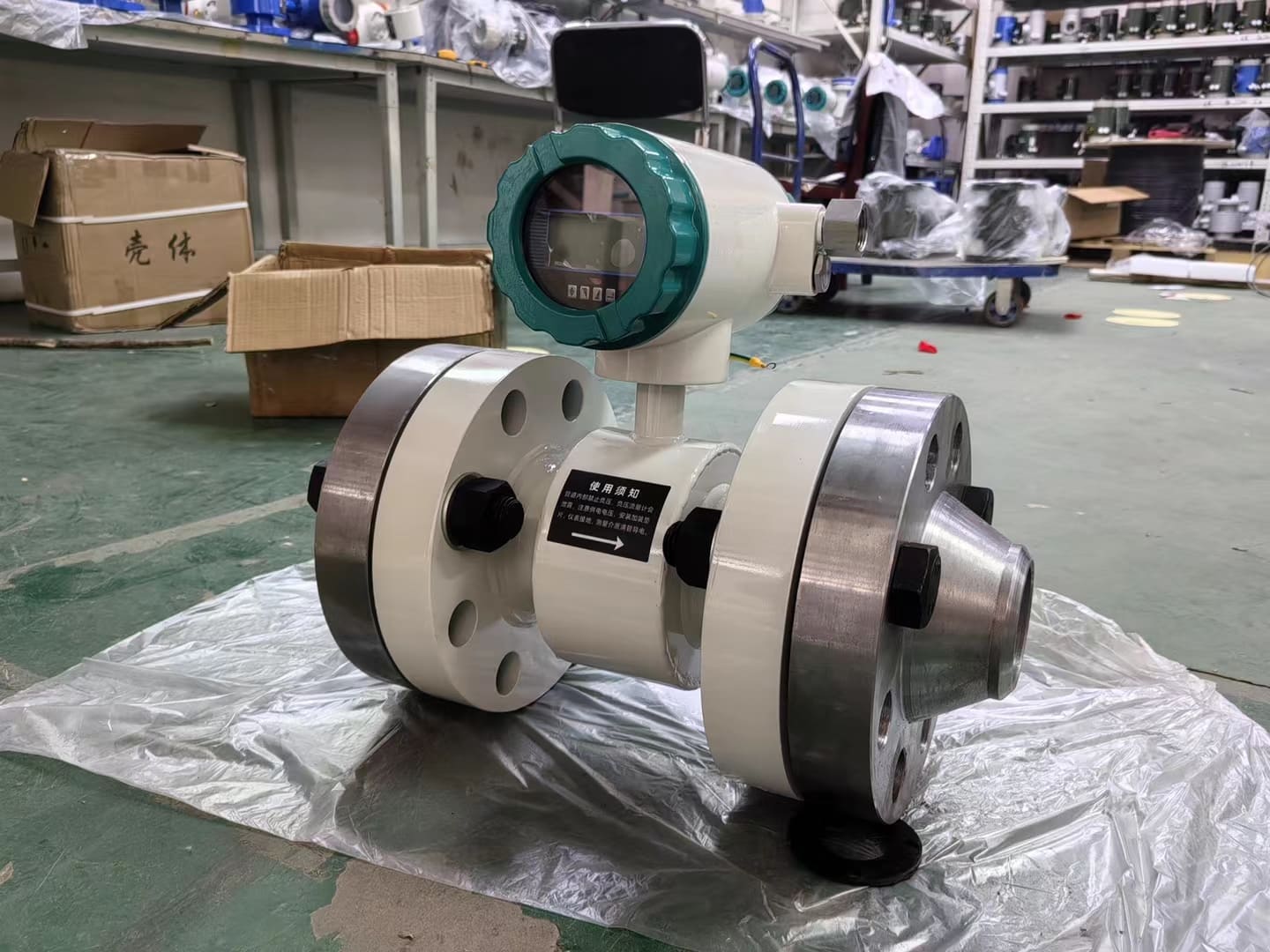

The form of electromagnetic flowmeter grounding ring is divided into ordinary type and protection type, generally use ordinary type, if the measured medium is wear, it is appropriate to use a protective grounding ring with neck to protect the lining of the inlet end and extend the service life. If the diameter of the electromagnetic flowmeter is less than 200mm, when the polytetrafluoroethylene lining is selected, the grounding ring should be selected to ensure that the lining is protected from damage when the pipeline is installed. The ground ring is usually stainless steel or Hc alloy.

Electromagnetic flowmeter grounding method, need to pay attention to the following points:

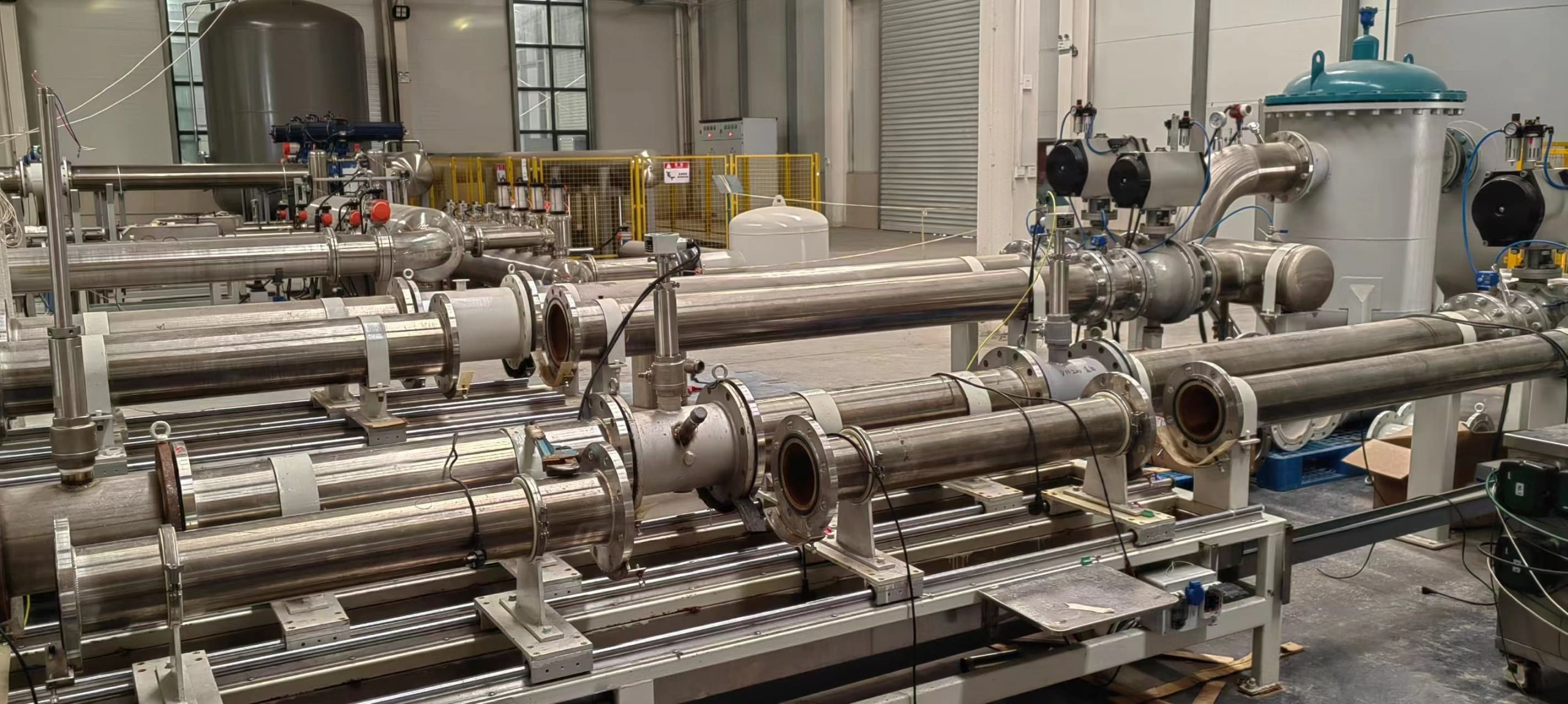

1. The measuring tube, housing, shielding wire, converter and secondary instrument of the sensor should be grounded.

2. The sensor and converter should be grounded separately, absolutely not connected to the motor and process pipeline, and the grounding resistance should be less than 10 ohms.

3. The grounding of the sensor and converter is on site, and the shielding layer of the secondary instrument is grounded on one side of the control room. Do not ground multiple terminals to avoid interference due to different potentials.

4. The sensor is installed on a metal pipe, and the grounding wire of the sensor can be connected to the pipe flange according to the requirements of the manufacturer to form a reliable grounding loop. The ground point of the instrument should be an independent ground point, and is not allowed to be grounded with other electrical equipment.

A good grounding can not only improve the accuracy of the flowmeter, but also have a better effect on the service life of the electromagnetic flowmeter and the prevention of lightning strikes.

-.jpg)