What are the key points for reference selection of intelligent electromagnetic flowmeters

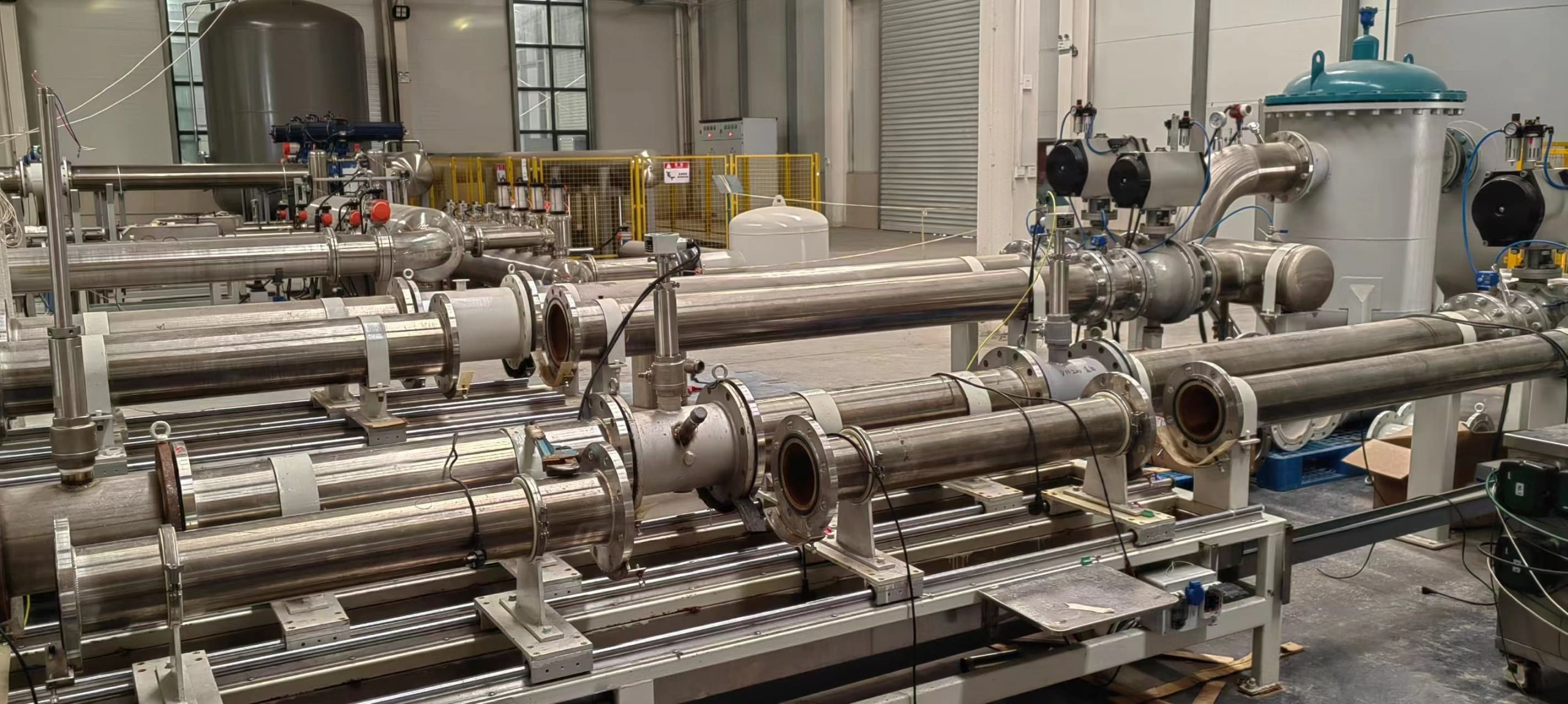

The intelligent electromagnetic flowmeter is mainly used to measure the volume flow of conductive liquids and slurries in closed pipelines, including strongly corrosive liquids such as acids, alkalis and salts. Electromagnetic flowmeters are widely used in industries such as petroleum, chemical engineering, metallurgy, textile, food, pharmaceuticals, and papermaking, as well as in fields like environmental protection, municipal management, and water conservancy construction.

Key points for reference selection of intelligent electromagnetic flowmeters:

Based on the name and properties of the medium to be measured known, determine whether to use an electromagnetic flowmeter

Note: Electromagnetic flowmeters can only measure the flow of conductive liquids, while gases, oils and the vast majority of organic liquids are not included in general conductive liquids

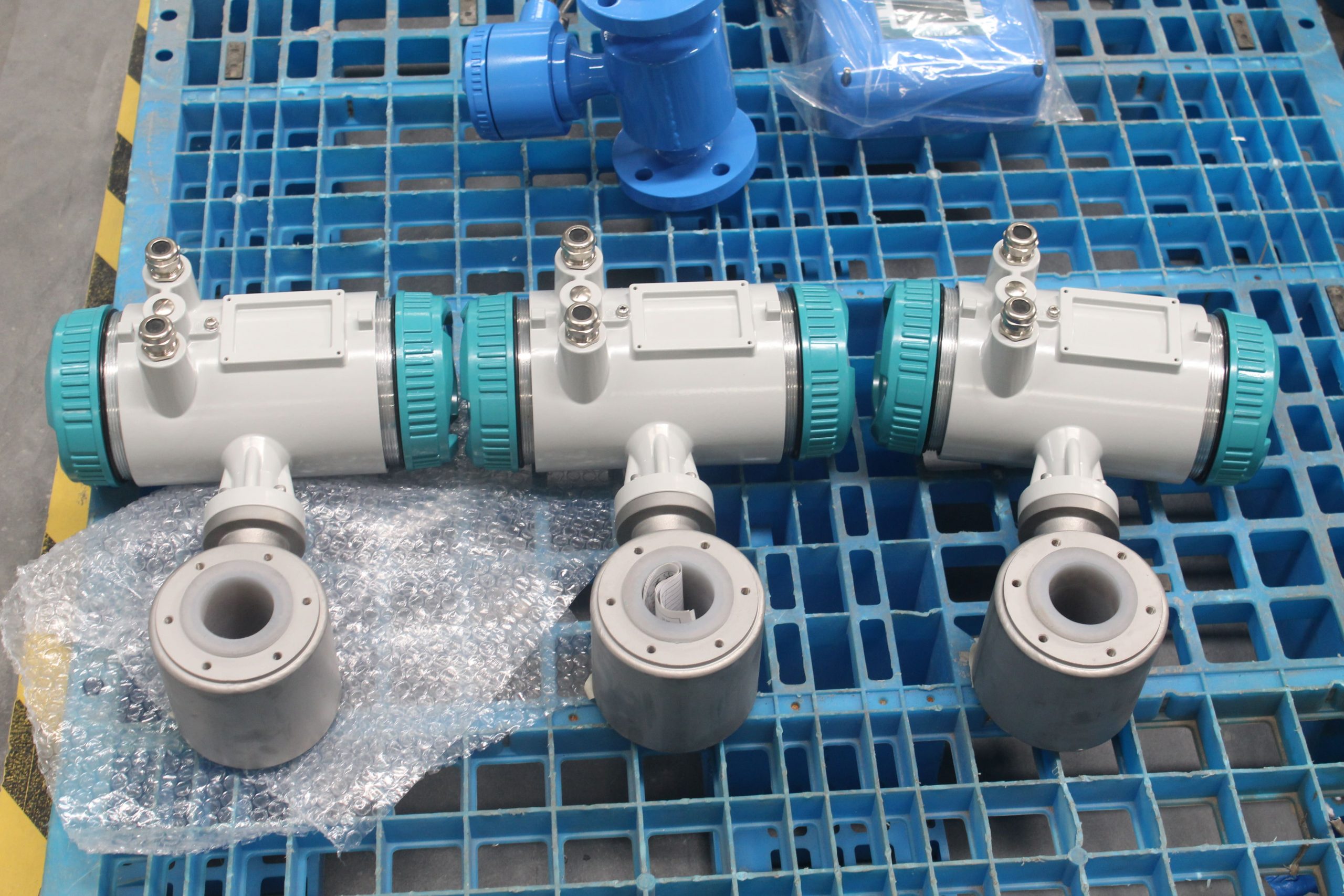

2. Determine the electrode material based on the properties of the medium known

Attention; The company generally offers four types of electrodes: stainless steel, Hastelloy, titanium and tantalum. The choice of electrode should be based on the properties of the medium and refer to relevant data manuals. You can also contact the staff of the flowmeter manufacturer for assistance in selection.

3. Determine whether to use rubber or PTFE lining based on the known medium temperature

Note: The temperature resistance of rubber must not exceed 80 ° C.

Ptfe can withstand a temperature of 150 ° C and can withstand 180 ° C for an instant.

Urban sewage can generally be treated with rubber linings and stainless steel electrodes

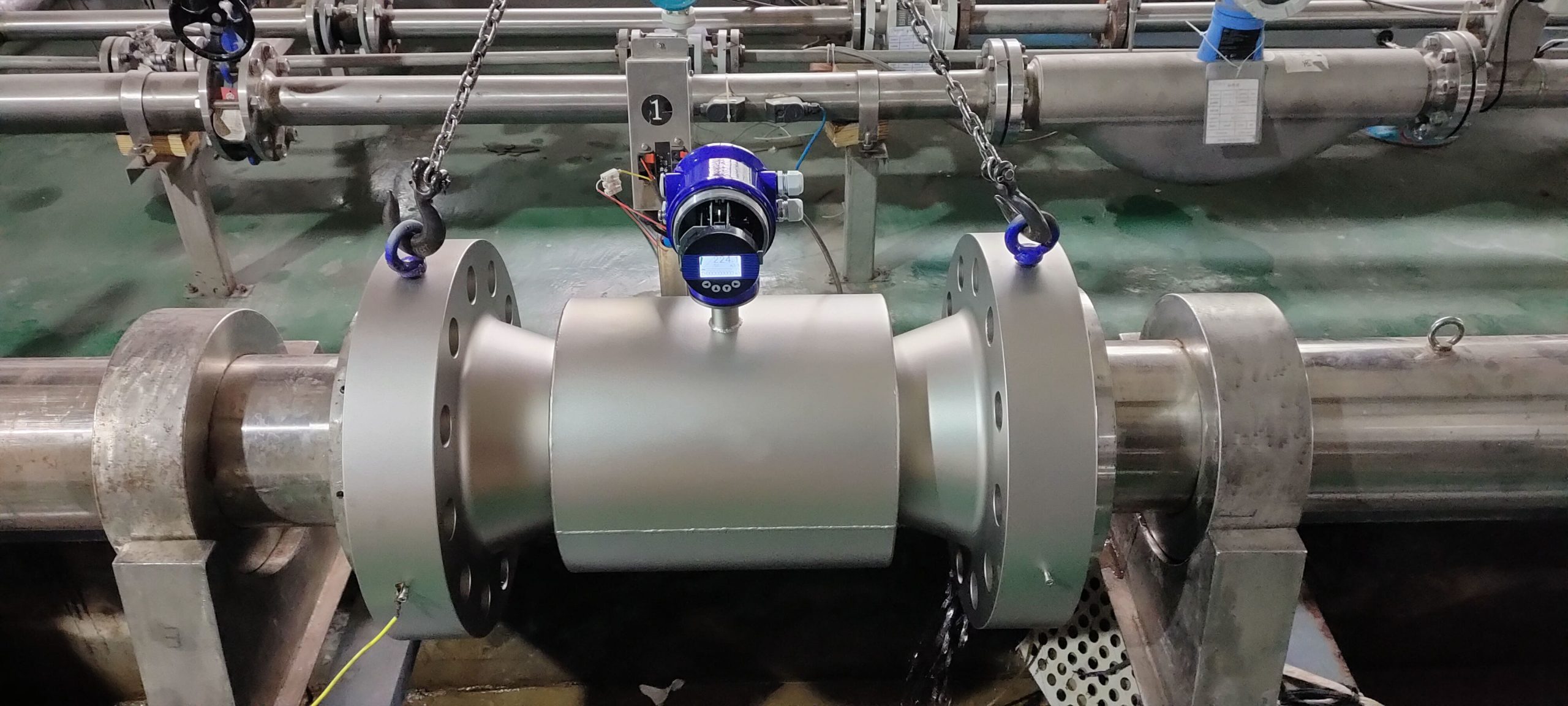

4. Select the flange specification of the gauge body based on the known medium pressure

Note: The specification of electromagnetic flanges is usually that when the diameter ranges from DN10 to 250, the rated pressure of the flange is ≤1.6Mpa.

When the diameter ranges from DN250 to 1000, the rated pressure of the flange is ≤1.0Mpa.

When the actual pressure of the medium is higher than the above-mentioned range of pipe diameter – pressure, it is a special order. You can contact the staff of the flowmeter manufacturer.

5. Determine the electrical conductivity of the medium

Note: The conductivity of the electromagnetic flowmeter must not be lower than 5 μ s /cm. The electrical conductivity of tap water is approximately tens to hundreds of micrometers per centimeter. Generally, soft water from boilers (deionized water) conducts electricity, while pure water (highly distilled water) does not. The electrical conductivity of gases, oils and the vast majority of organic liquid substances is far below 5uS/cm and they are non-conductive.

-.jpg)