Choose flow meter, need to know what?

When selecting the flow meter, the appropriate flowmeter should be selected according to the actual parameters on site.

1. Model selection

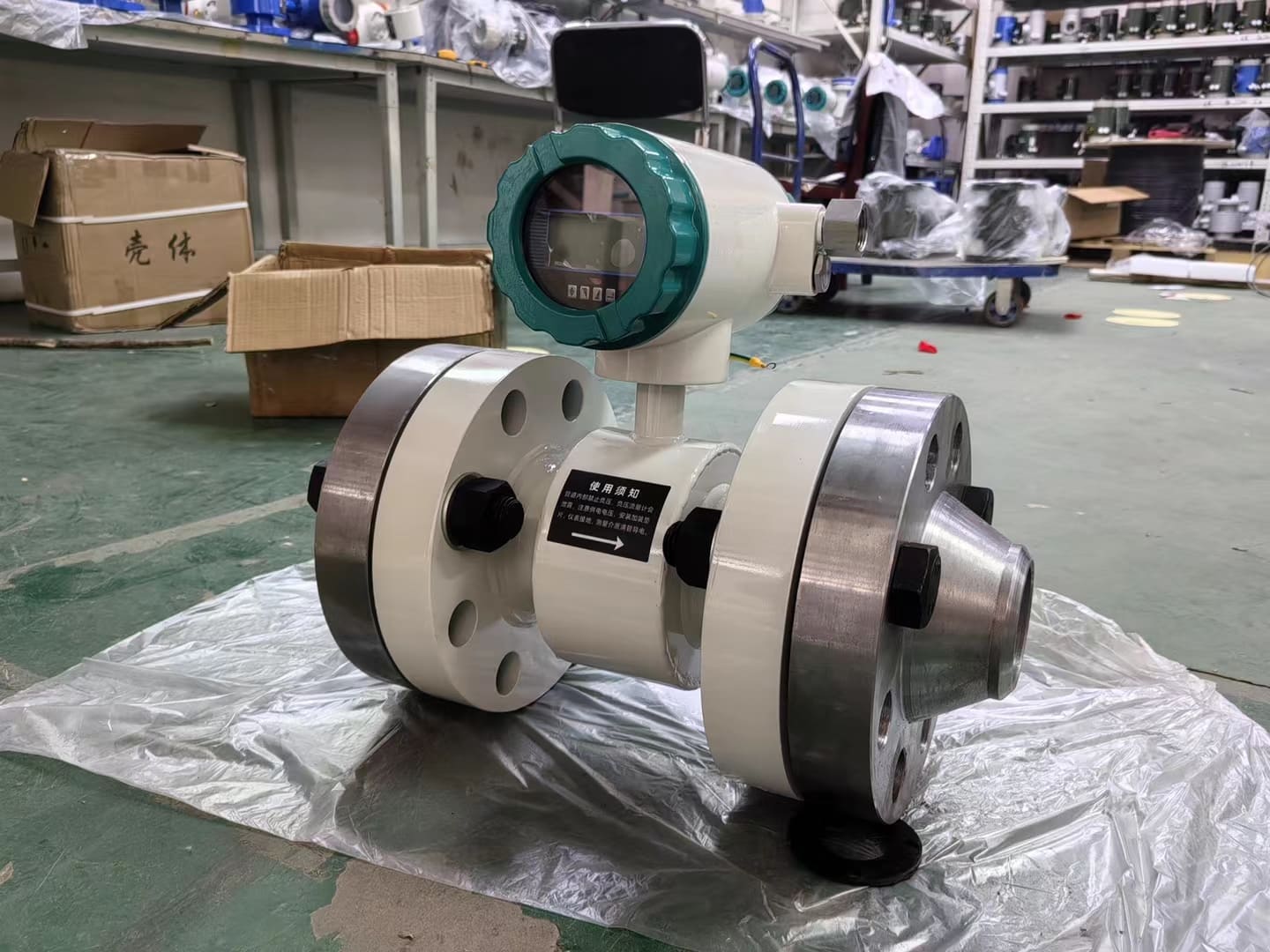

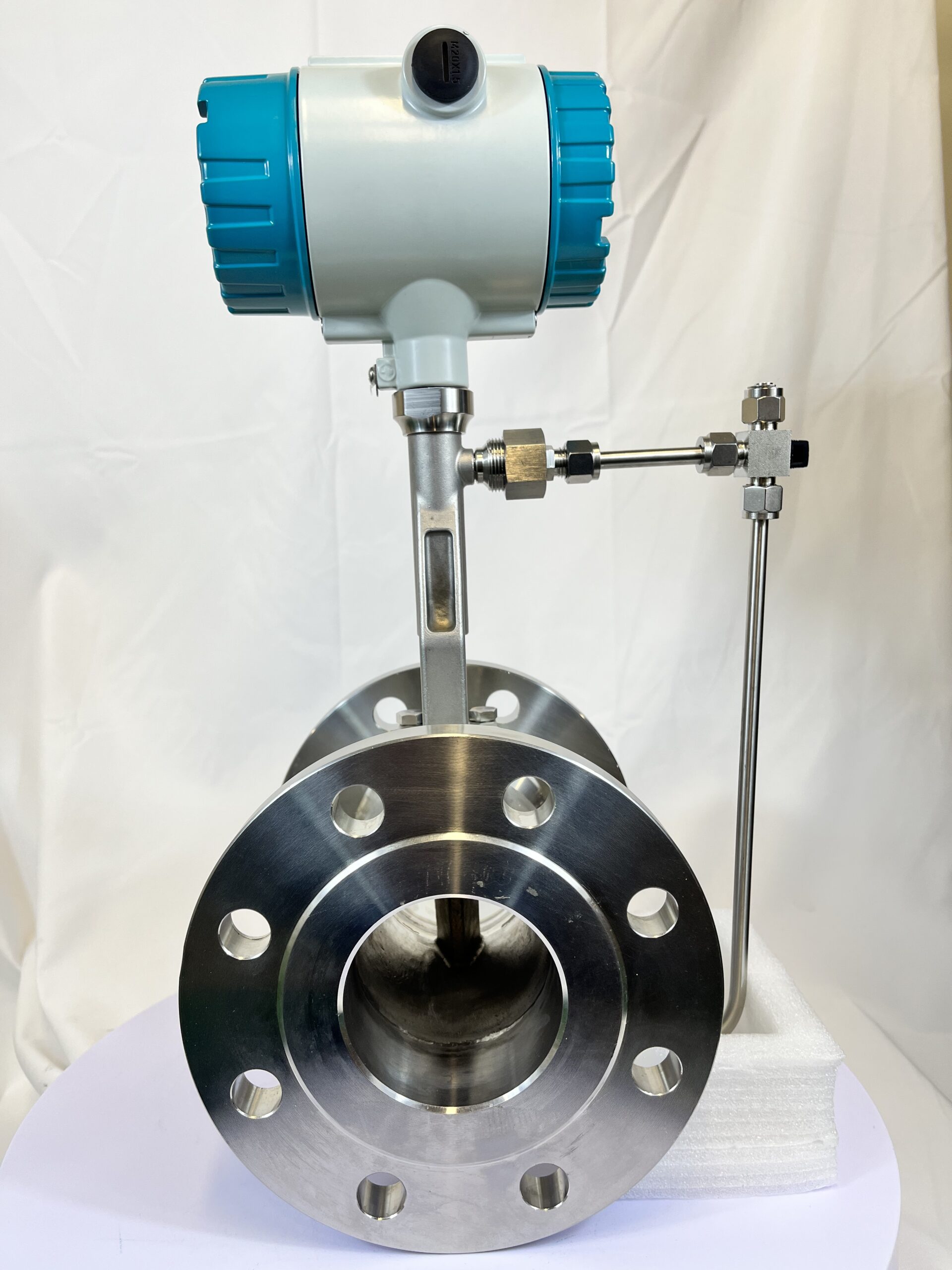

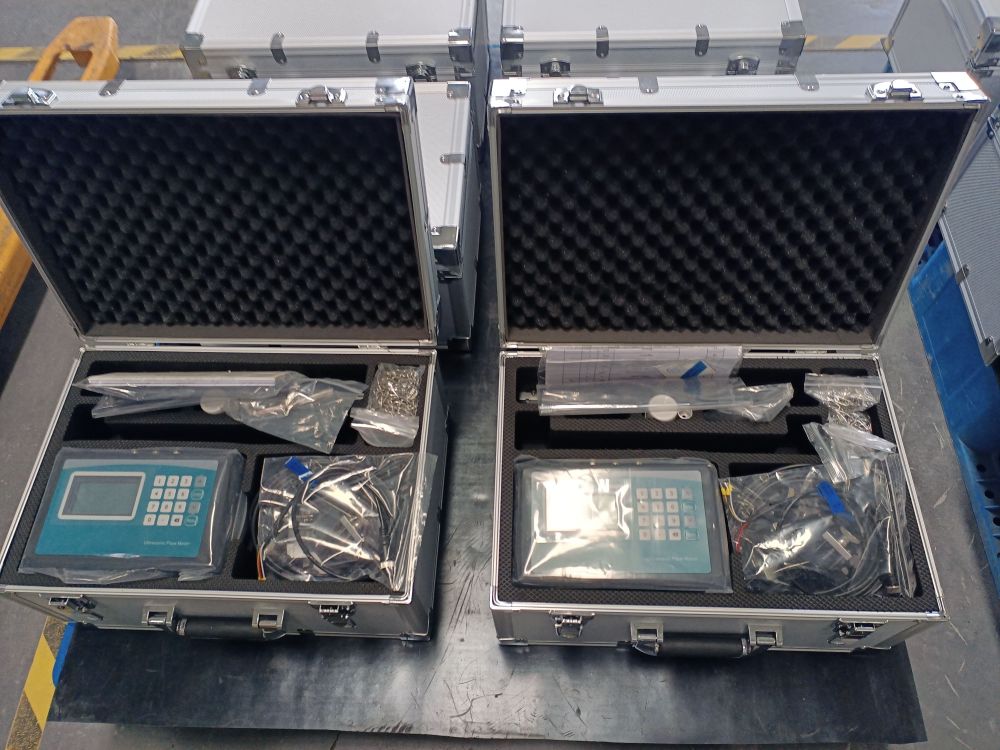

Intelligent liquid crystal integrated electromagnetic flowmeter can be selected in ordinary occasions, split electromagnetic flowmeter can be selected in occasions where it is not convenient to read data, small pipe diameter to select pipe segment connection, large pipe diameter to select plug-in connection.

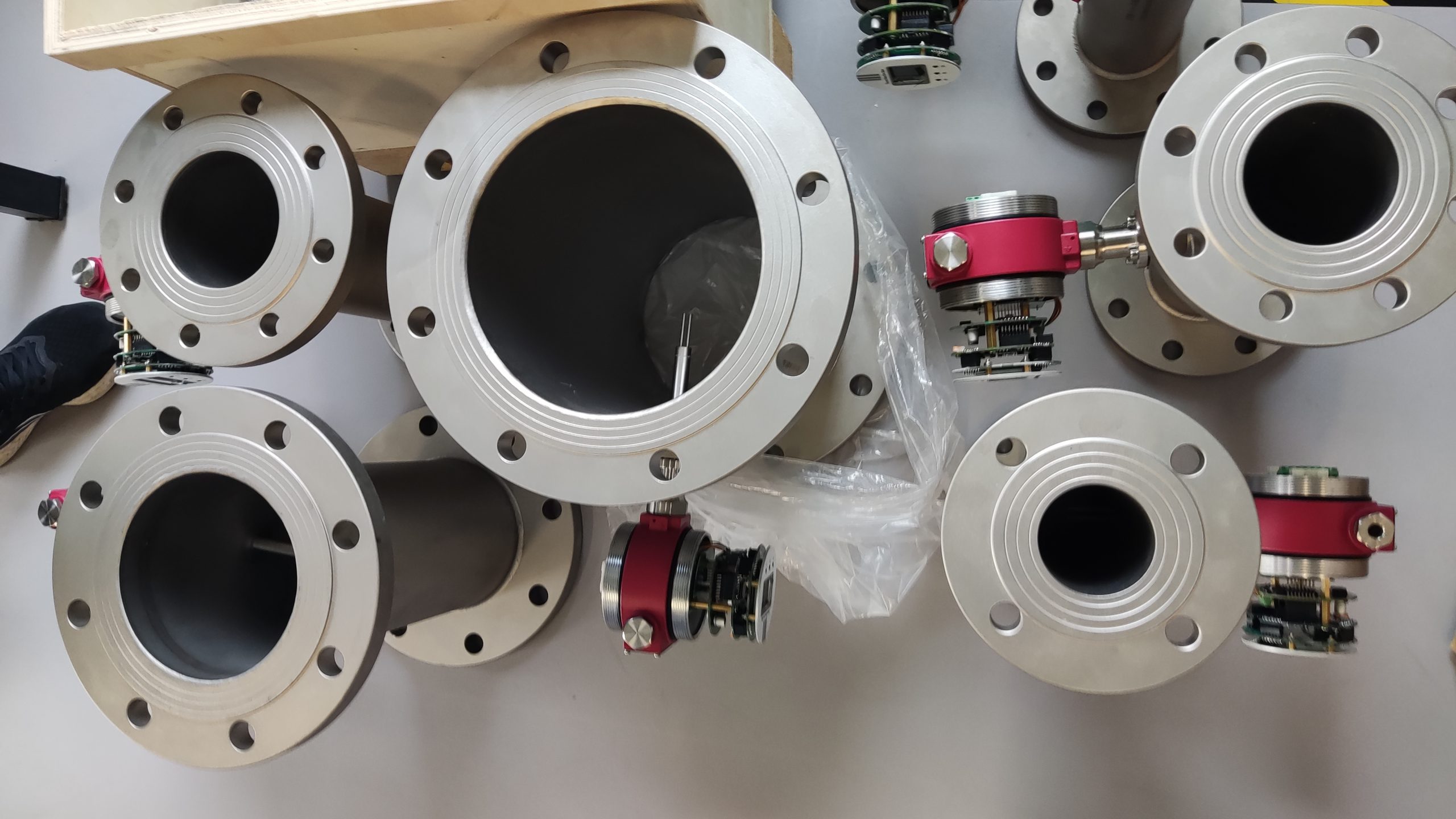

2. Choice of caliber

Select a sensor of the same caliber as the connected process pipe, the premise of selecting the same caliber is that the flow rate of the fluid in the pipe must be in the range of 0.3m/ S-10m /s; It is suitable for use in the early stage of the project and the fluid flow rate in the pipe is low.

3. Choice of lining

The selection of lining should be based on the actual situation of the measured medium, such as the corrosion of the medium, temperature, etc., select the appropriate lining to ensure the normal use of the flowmeter.

4. Selection of electrode materials

The electrode material selection should be selected according to the corrosion of the measured medium, and the manufacturer should be informed of the details of the medium when communicating with the manufacturer in the early stage.

5. Selection of protection level

Electromagnetic flow meters have a variety of protection levels, and different installation occasions require different protection levels, which are selected according to the installation environment.

6. Power supply mode, according to the customer’s field conditions to choose different power supply mode of electromagnetic flowmeter.