Description of several methods of electromagnetic flowmeter against interference

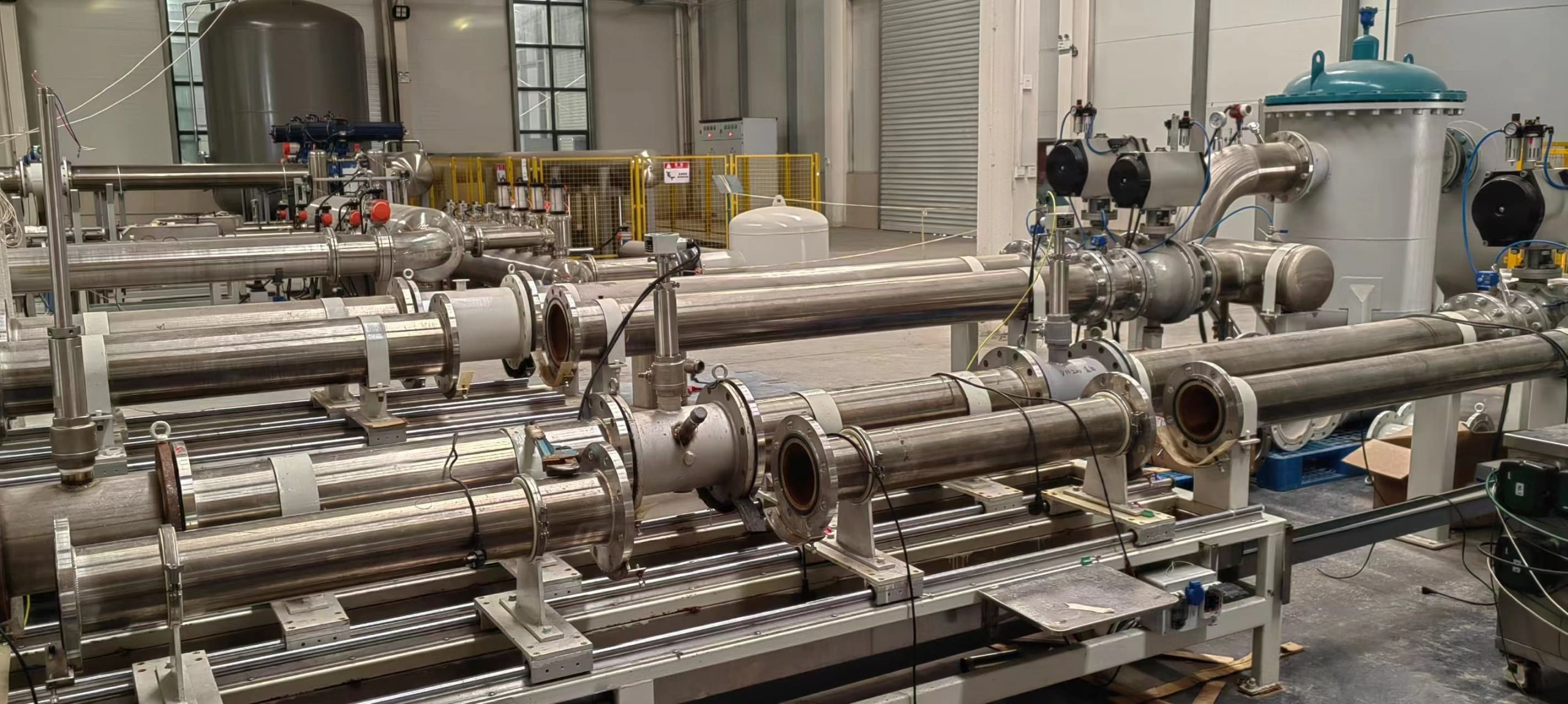

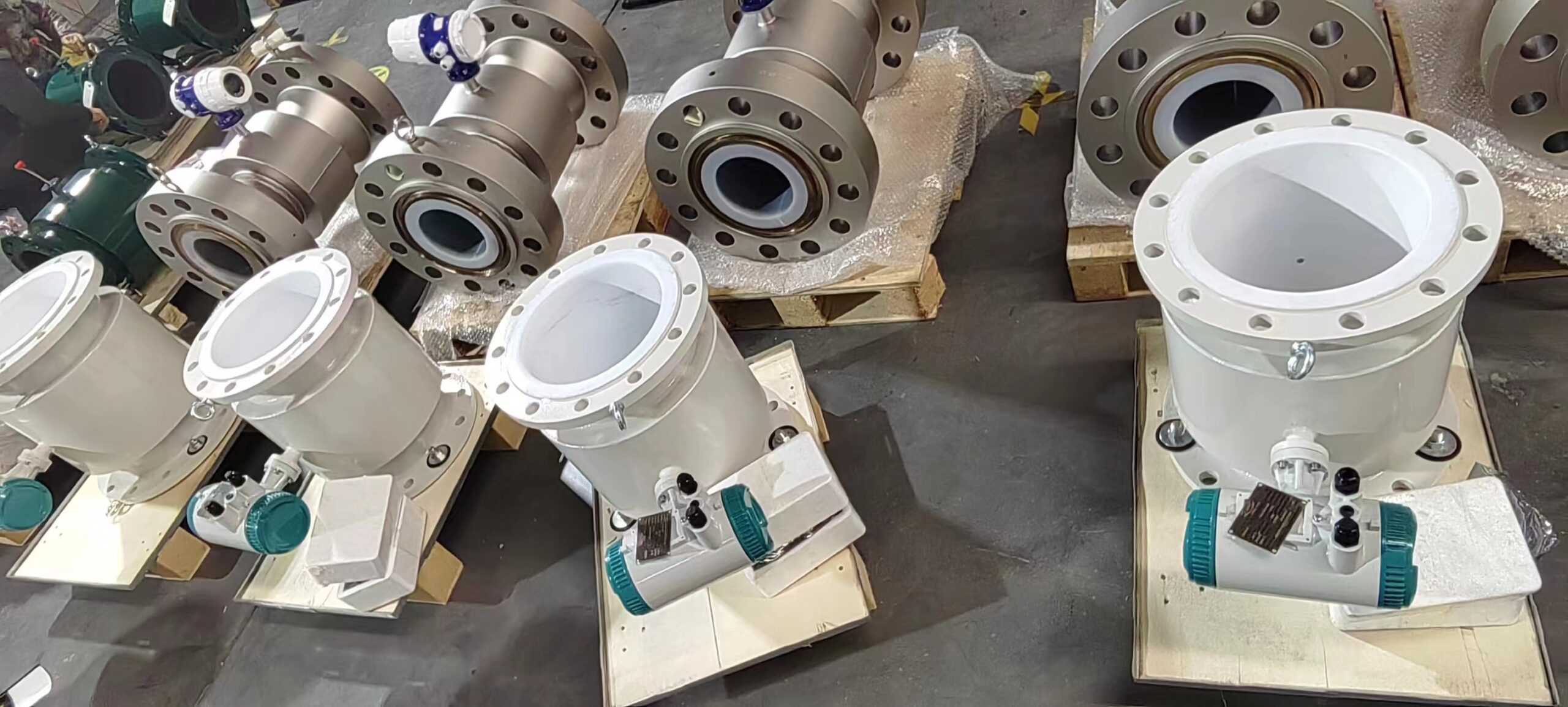

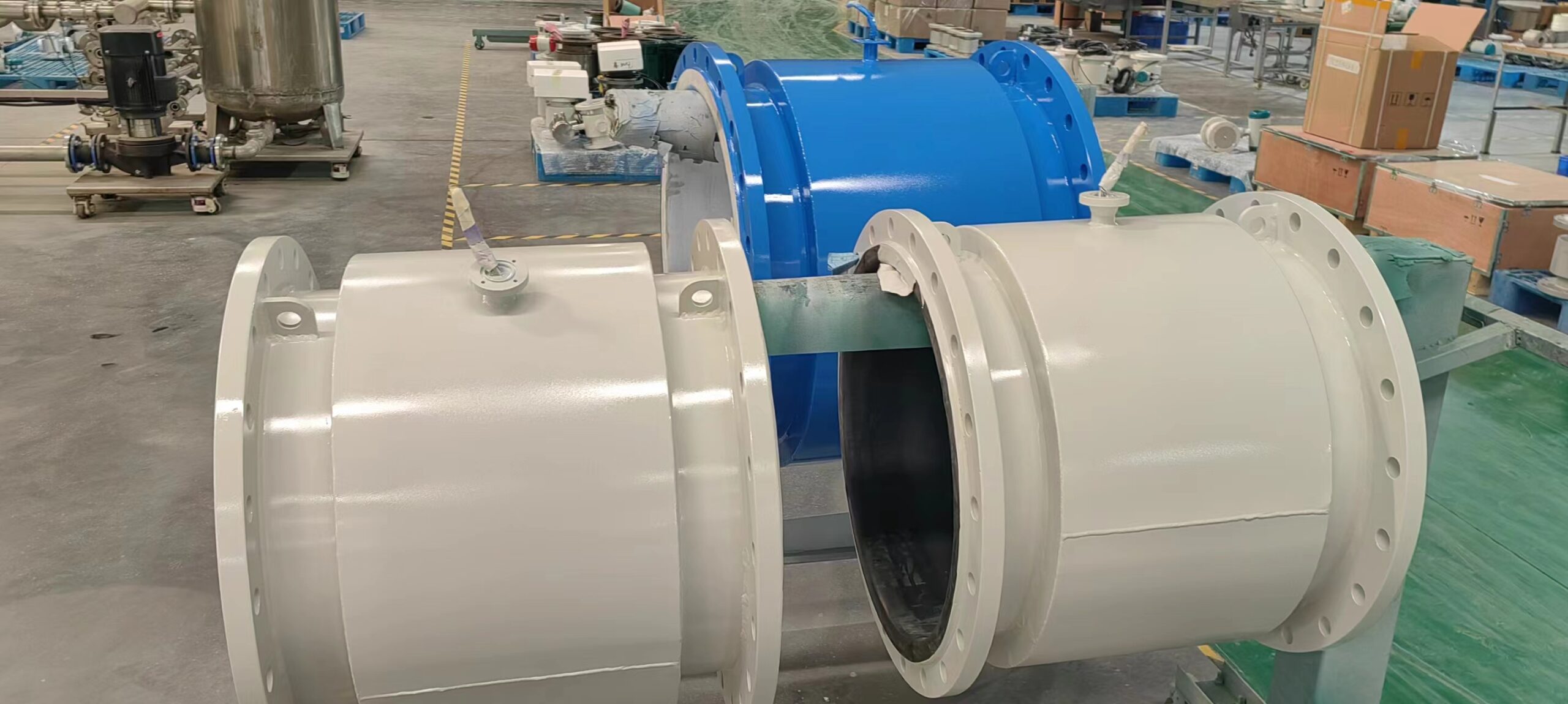

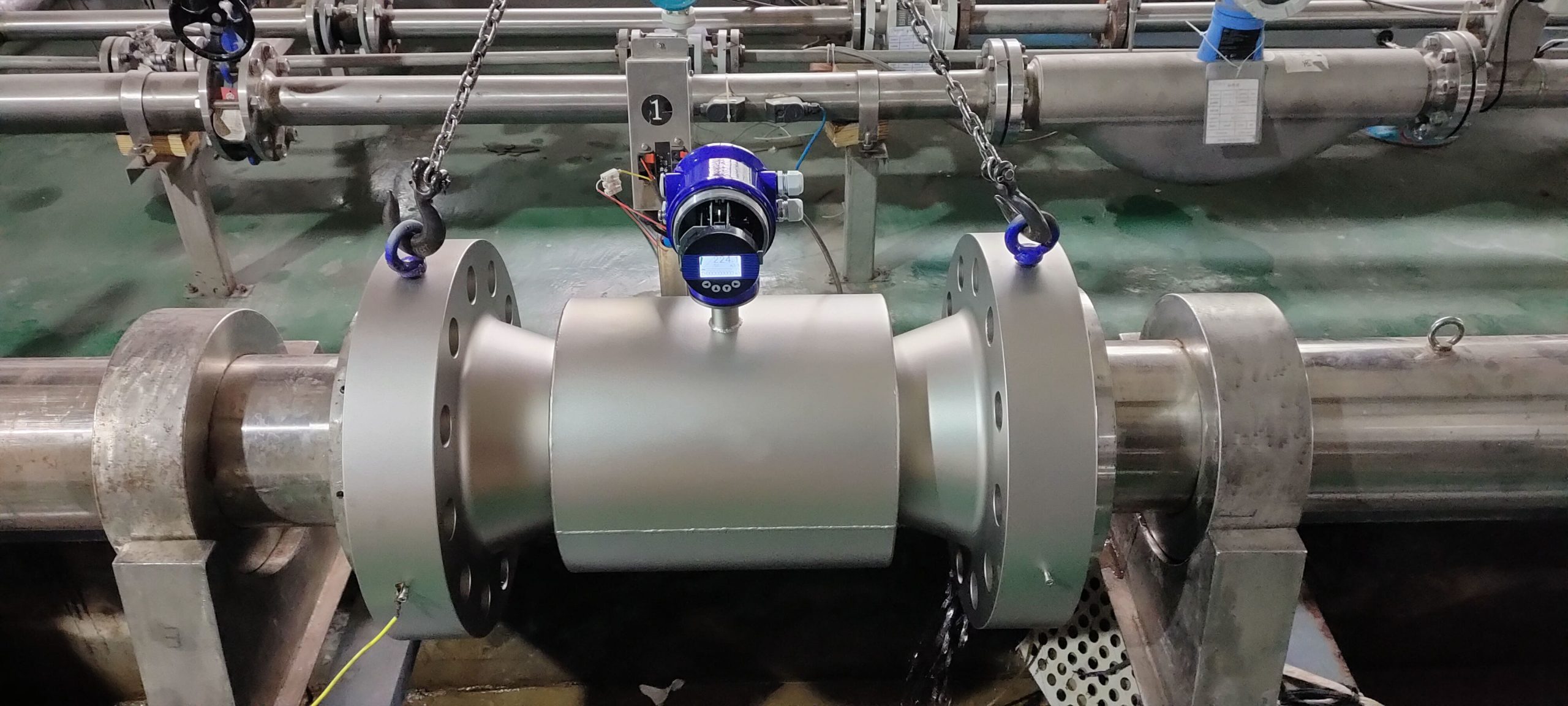

Electromagnetic flowmeter is designed for the measurement of conductive liquid instrument, its high accuracy, wide range ratio, internal no moving parts, open flow parts, no pressure loss. Excellent corrosion resistance, high pressure resistance, strong adaptability, has been widely used in various production fields. Because some installation sites are more complex, it is inevitable to produce a variety of interference, Aister instrument to explain several common electromagnetic flow meter anti-interference methods:

Zeroing of the sensor: To eliminate the orthogonal interference caused by electromagnetic interference, two wires are connected to both ends of the potentiometer at one place on the elevator. The lead wire on the other electrode and the middle end of the potentiometer are respectively connected to the inlet end of the converter. At this point, two closed loops are formed, producing their own induced electromotive force and current. Two currents are added to the input resistance of the converter through the middle end of the potentiometer, at this time the direction of the two currents is opposite, before use, adjust the position of the contact point in the middle end of the potentiometer, so that the two currents are the same size, you can cancel each other. However, due to the limitations of the production process, this operation can not completely eliminate the impact of electromagnetic interference, and other methods are needed to further eliminate the impact of interference when necessary.

Synchronous sampling technology: When the signal is continuous, the synchronous sampling technology can be used to sample the signal. However, attention should be paid to the selection of sampling area, width and starting point of sampling area. The sampling period is selected as an integer multiple of power frequency, so that even if the signal suffers from interference because its sampling time is a complete power frequency cycle, its average value is zero, which can effectively suppress the influence of interference.

Digital filter technology: This technology is a more common technology in intelligent instruments, which can effectively complete the function that the analog filter can not be completed. It is easy to solve pulse interference, digital circuit interference, S/D converter high-frequency interference, etc.

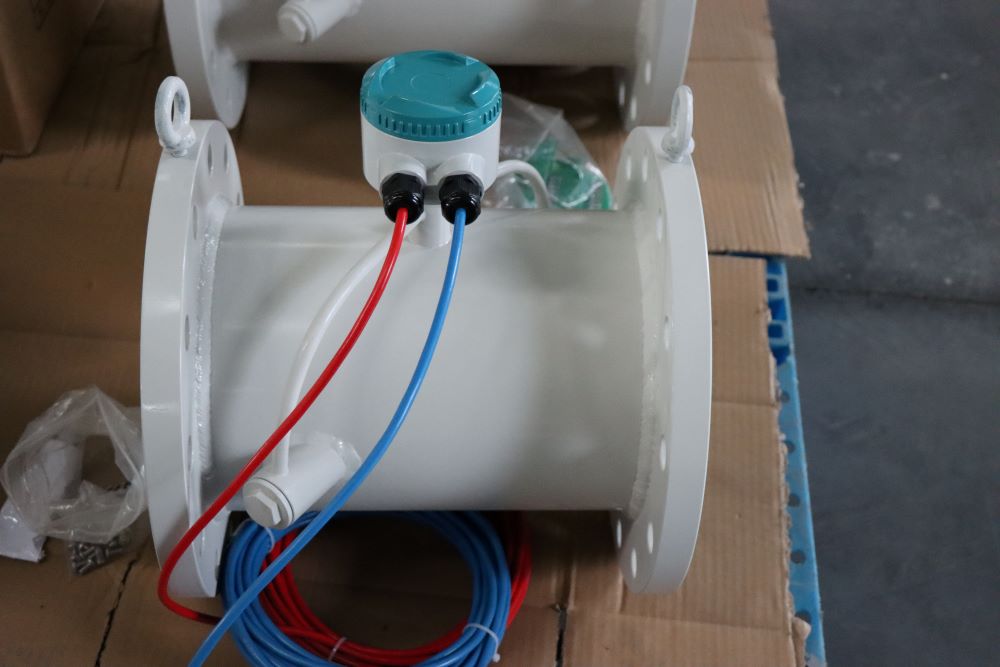

Effective grounding of the instrument: the sensor output signal of the electromagnetic flowmeter is very small, in order to improve the anti-interference ability of the instrument, the zero potential of the sensor input loop must be grounded. At the same time, the grounding of the sensor measuring tube shell can play a shielding role to reduce the electromagnetic interference of the outside world and the excitation system itself. When the flowmeter is grounded, it must be grounded separately to avoid sharing ground with other meters. The ground point of the meter should be far away from large mechanical and electrical equipment to prevent the leakage current in the ground wire from interfering with the measurement signal in series mode.