Are there any requirements for straight pipe sections for ultrasonic flowmeters

When installing ultrasonic flowmeters, the requirements for the straight pipe section are very crucial. This is mainly because the straight pipe section can ensure that the fluid flow state through the flowmeter is stable and uniform, thereby improving the measurement accuracy. The following is a detailed analysis of the requirements for the straight pipe section of ultrasonic flowmeters:

The importance of straight pipe sections

Ensure the flow state: The straight pipe section can ensure that the fluid forms a typical flow velocity distribution (such as laminar flow velocity distribution and turbulent flow velocity distribution) when passing through the pipe. This distribution is stable and predictable, which is conducive to the accurate calculation of ultrasonic flowmeters using mathematical models.

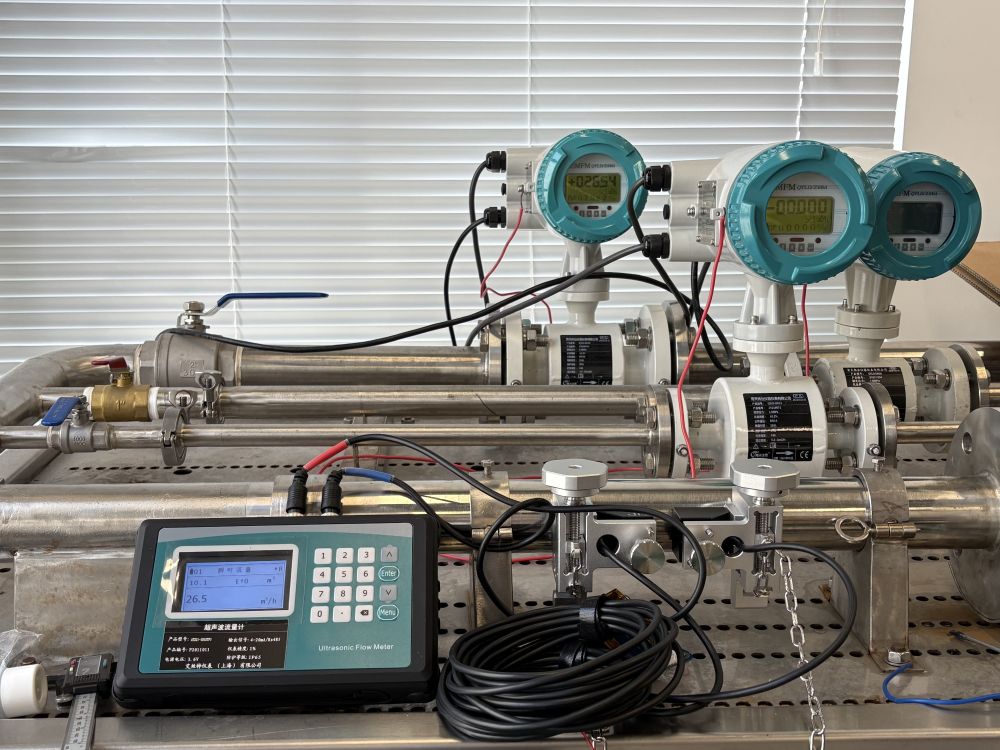

Reduce interference: Pipe bends, valves, pumps and other pipe fittings can change the flow state of the fluid, generating vortices, asymmetric velocity curves and other interference factors, all of which will reduce the measurement accuracy of ultrasonic flowmeters. Straight pipe sections can reduce the influence of these interfering factors.

2. Specific requirements for straight pipe sections

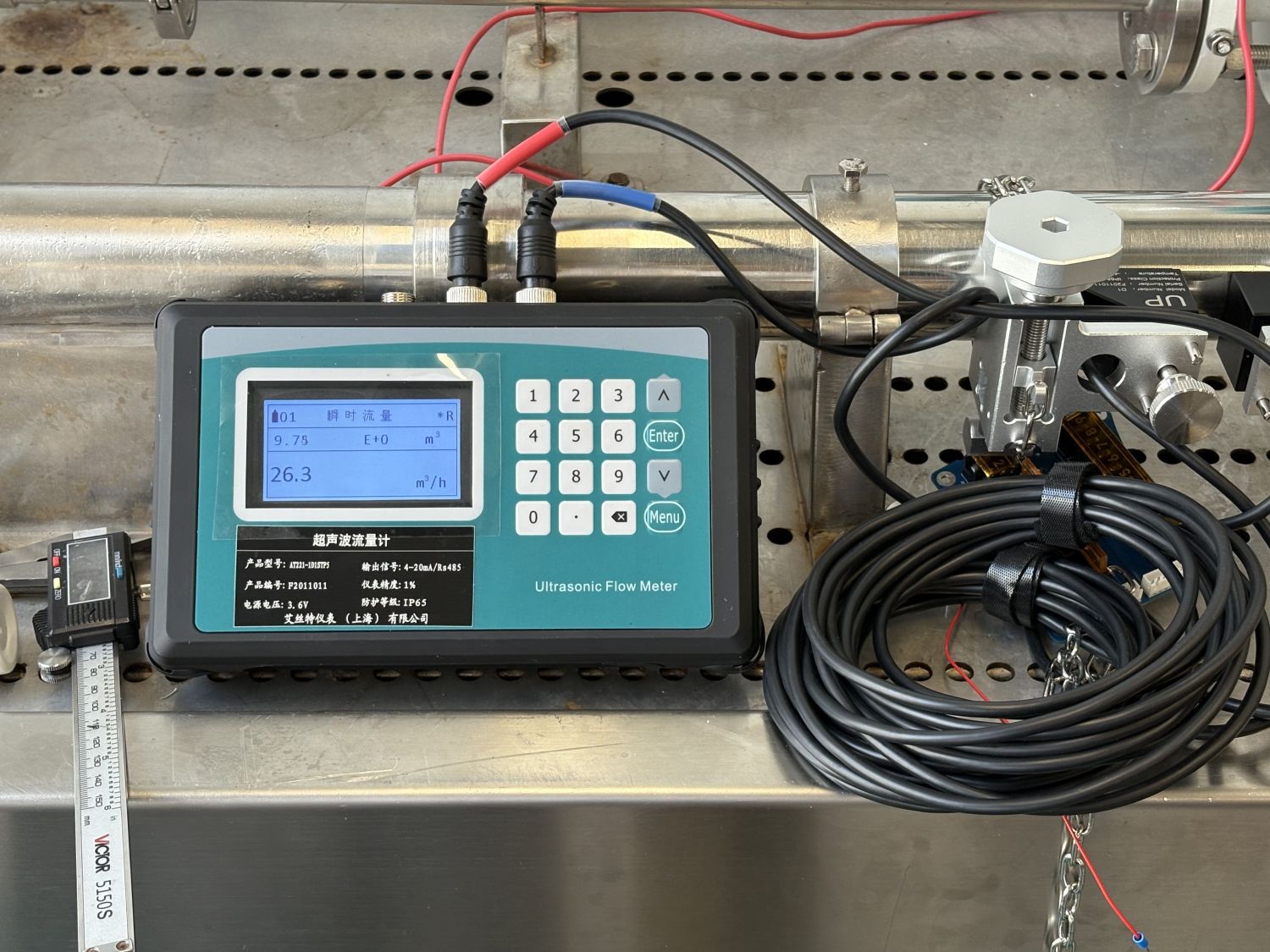

Length requirement: Generally, the installation position of the ultrasonic flowmeter needs to meet the requirement of a straight pipe section of 10D before and 5D after (D is the pipe diameter). If there are complex pipe fittings such as pumps and valves in the pipeline, it is even more necessary to reserve a longer straight pipe section, such as 30D. Such a length requirement is to ensure that the fluid has sufficient distance to return to a stable flow state both before and after passing through the flowmeter.

Pipe conditions: In addition to the length requirements, the straight pipe sections also need to keep the inner walls smooth, free of rust and scale, etc., to reduce the obstruction and interference with fluid flow.

3. Handling methods for insufficient straight pipe sections

Installation of flow regulators: Flow regulators can be used to reduce the length of the upstream straight pipe section, compensating for the insufficiency of the straight pipe section by adjusting the flow state of the fluid.

Pipeline modification: If the on-site conditions permit, the existing pipelines can be modified through consultation with equipment professionals to meet the requirements of the ultrasonic flowmeter for straight pipe sections.

Summary: The requirement for straight pipe sections of ultrasonic flowmeters is one of the key factors to ensure their measurement accuracy. When installing an ultrasonic flowmeter, it is necessary to reserve sufficient straight pipe section length strictly in accordance with the requirements and ensure that the pipeline conditions are good. If the on-site conditions cannot meet the requirements of the straight pipe section, measures such as installing flow regulators or modifying the pipeline can be taken to solve the problem.

Please note that the above information is for reference only. The specific installation requirements may vary due to factors such as the model of the ultrasonic flowmeter, pipeline conditions, and fluid characteristics. In practical applications, it is recommended to consult professionals for installation and commissioning based on specific circumstances.