What are the key points for using handheld ultrasonic flowmeters

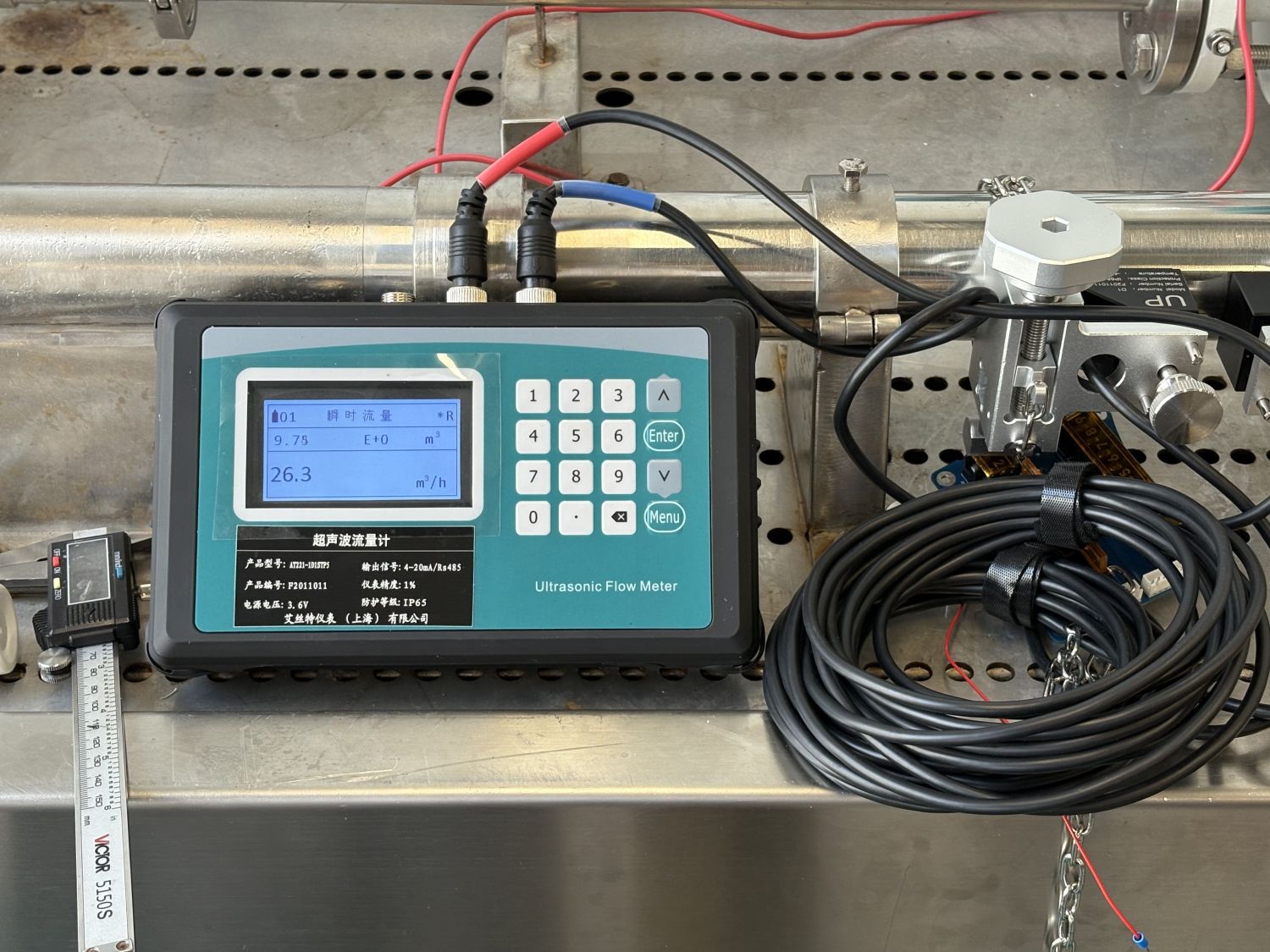

Handheld ultrasonic flowmeters are commonly used tool instruments for flow detection. It is designed to enhance the convenience of flow measurement. It features high measurement accuracy, a large range ratio, no pressure loss, no moving parts, and is compact and lightweight.

The flow measurement can be completed simply by installing the sensor on the outer wall of the pipeline. Handheld ultrasonic flowmeters are widely used in industries such as water supply, heating, water conservancy, metallurgy, chemical engineering, and machinery. They can be used for production monitoring, flow comparison, temporary detection, and flow inspection, and are commonly used instruments for flow detection. It is particularly suitable for flow balance testing and flow monitoring: drinking water, river water, seawater, cooling water, hot water, industrial wastewater, lubricating oil, diesel, fuel oil, chemical liquids, etc.

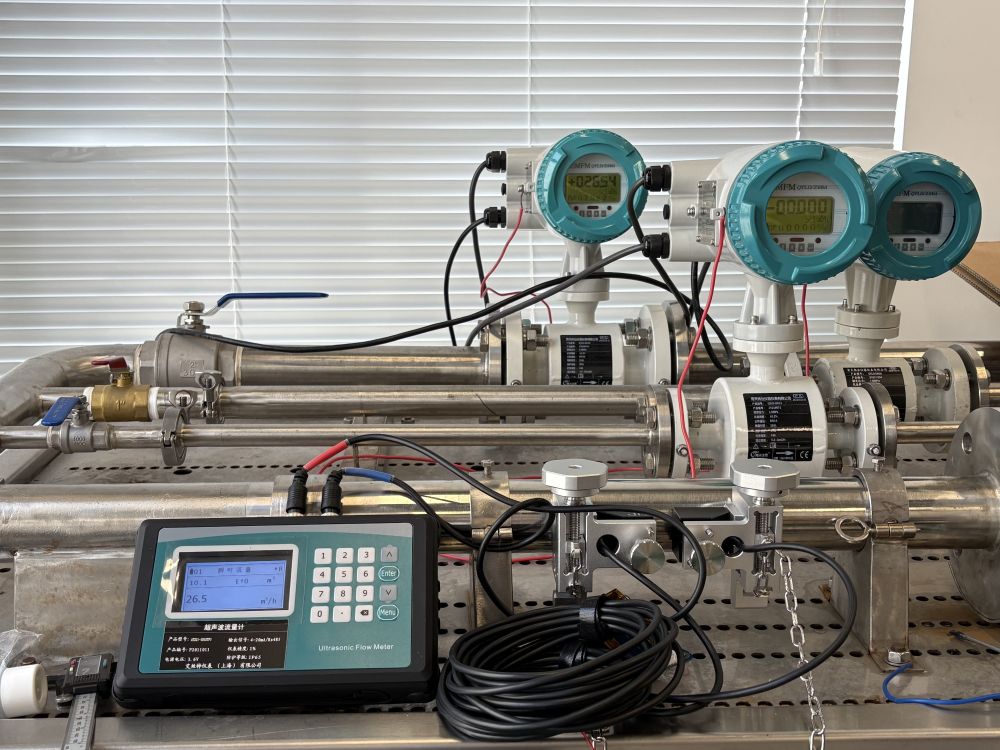

The installation methods of handheld ultrasonic flowmeters are divided into two types: bracket installation and clamp installation.

The clamp-on installation requires the external clamp-on sensor to be attached to the outer wall to easily complete the flow measurement. The installation is very convenient and does not require cutting off the pipe section. It has low consumption cost and no pressure loss. The fixing method is simply to fix it with a metal clamp. The bracket installation simplifies the installation process of the ultrasonic flowmeter sensor and shortens the installation time. Moreover, there are direct scales on the bracket, which improves the installation accuracy. It is also highly corrosion-resistant and durable, and is usually fixed with steel bracket chains. When using it, it should be noted that the ultrasonic flow rate is afraid of air bubbles. When there are impurities or air bubbles in the heat network that will affect the final strategic result, we should avoid measuring the areas with impurities and air bubbles. Of course, before measurement, it is also possible to choose to remove these air bubbles and impurities, otherwise it will affect the result.

For handheld ultrasonic flowmeters, due to concerns that impurities may affect the final measurement results, the turbidity of the liquid can be measured by the time difference method, and then the turbidity of the liquid can be measured by the time difference method. Different handheld ultrasonic flowmeters have requirements for the applicable range of water quality. Some measuring instruments can measure in places with high impurity turbidity, so it is necessary to select appropriate measuring instruments. When choosing a handheld ultrasonic flowmeter, there are still many points to note. For instance, it is necessary to ensure that the battery quality is good to prevent it from becoming unusable due to battery wear and tear. Also, it is recommended to have the habit of charging after each use. It is suggested not to use the device during the charging process, as this can cause too much damage to the battery. After normal use, simple cleaning should be done and it should be stored in a place free from direct sunlight and where the air humidity meets the standard.