The differences between pipe-type ultrasonic flowmeters and insertable ultrasonic flowmeters

There are significant differences between pipe-type ultrasonic flowmeters and insertable ultrasonic flowmeters in many aspects. The following is a specific analysis of these differences

Structure and installation method

Pipe-type ultrasonic flowmeter

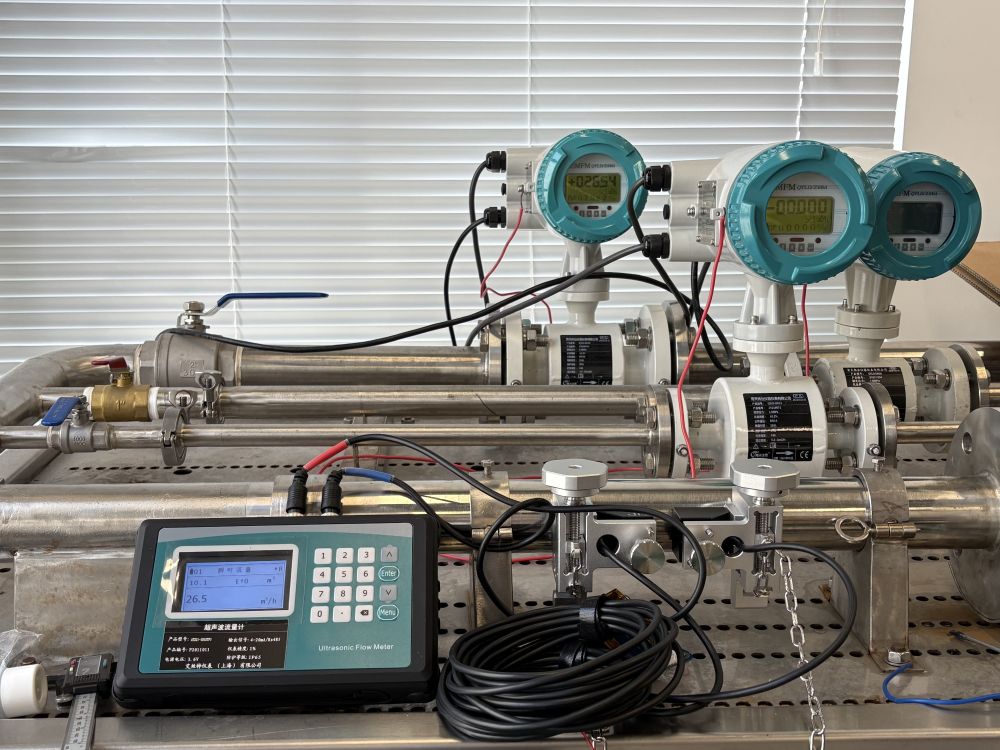

Pipe-type ultrasonic flowmeters usually refer to a type of ultrasonic flowmeter that combines a sensor with a measuring tube.

It measures fluid flow through a specific pipe section structure, which is installed in the pipeline. When the fluid passes through the pipe section, the speed and pressure of the fluid will affect the propagation speed and amplitude of ultrasonic waves, thereby calculating the flow rate.

There are various installation methods, including side installation, flange installation, etc., to meet the requirements of different pipeline systems.

Insertable ultrasonic flowmeter

The insertable ultrasonic flowmeter measures flow by inserting a probe into the pipeline.

This probe calculates the flow rate by using the speed difference of ultrasonic waves in the fluid. When ultrasonic waves propagate from the probe to the fluid, the speed in the direction of the current flow is faster than that in the direction of the current flow. By measuring these two speed differences, the flow rate of the fluid can be calculated.

The installation is simple and convenient. There is no need to cut off the pipe. Just drill a hole in the pipe and insert the probe.

2. Measurement accuracy and range

Pipe-type ultrasonic flowmeter

It usually has a relatively high measurement accuracy because a specific pipe section structure is adopted, which can better control the measurement conditions and reduce errors.

It has a wide measurement range and can meet the flow measurement requirements at different flow rates.

Insertable ultrasonic flowmeter

The measurement accuracy may be slightly lower than that of the pipe-type ultrasonic flowmeter because the measurement of the insertable probe is affected by various factors such as the state of the fluid in the pipeline and the position of the probe.

However, for large-diameter pipes, the insertable ultrasonic flowmeter offers an economical and effective measurement method.

3. Applicable scenarios and Maintenance

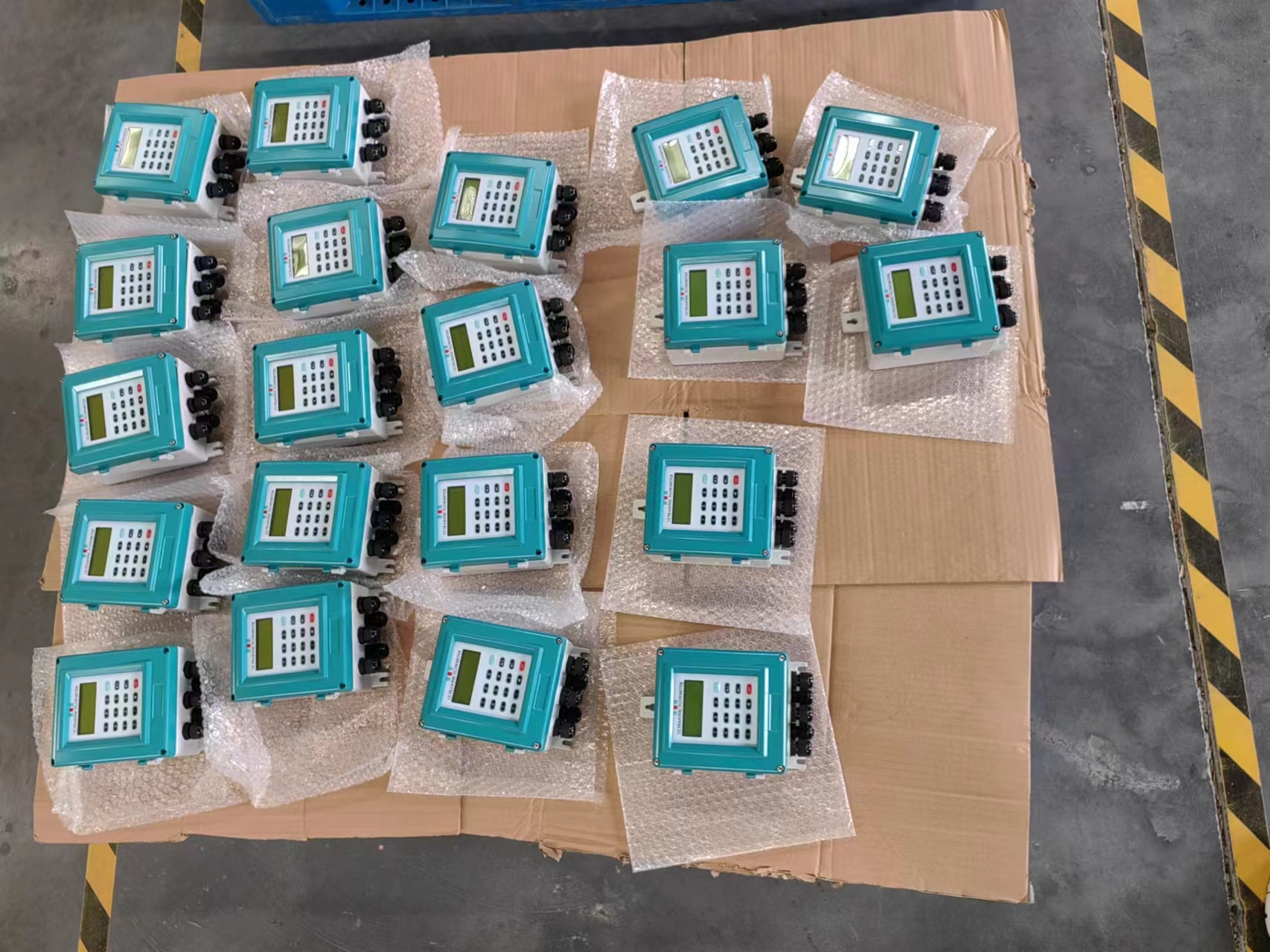

Pipe-type ultrasonic flowmeter

It is suitable for occasions that require long-term continuous measurement and have high requirements for measurement accuracy.

Due to its stable structure and good long-term stability, it may require more maintenance work during operation, such as regular checks on the cleanliness within the pipe sections.

Insertable ultrasonic flowmeter

It is suitable for large-diameter pipes or occasions with limited installation space, as there is no need to cut the pipes and the installation is simple.

It is convenient to maintain. The probe is easy to disassemble and replace, facilitating regular maintenance and cleaning.

4. Other features

Pipe-type ultrasonic flowmeter

It may have the characteristics of high temperature and high pressure resistance and be able to work stably in various harsh environments.

The design may be more complex to meet different measurement requirements.

Insertable ultrasonic flowmeter

The sensor has a simple structure, no throttling body, does not clog, and can display various parameters such as instantaneous flow rate and instantaneous flow velocity.

It has strong adaptability and sensors can be selected according to the diameter. It is suitable for pipes of various materials.

Summary: There are significant differences between pipe-type ultrasonic flowmeters and insertable ultrasonic flowmeters in terms of structure and installation methods, measurement accuracy and range, applicable scenarios and maintenance, as well as other features. When making a choice, users should make a comprehensive consideration and selection based on their actual needs and application scenarios.