Advantages of electromagnetic flow meter in sewage treatment

With the speeding up of urbanization process in our country, environmental pollution is increasingly serious. Because in sewage treatment, it is necessary to analyze and control the discharged sewage, additives, sludge, etc., so the flow measurement is very important. Among the many flowmeter products used for sewage measurement, electromagnetic flowmeter measurement accuracy is higher.

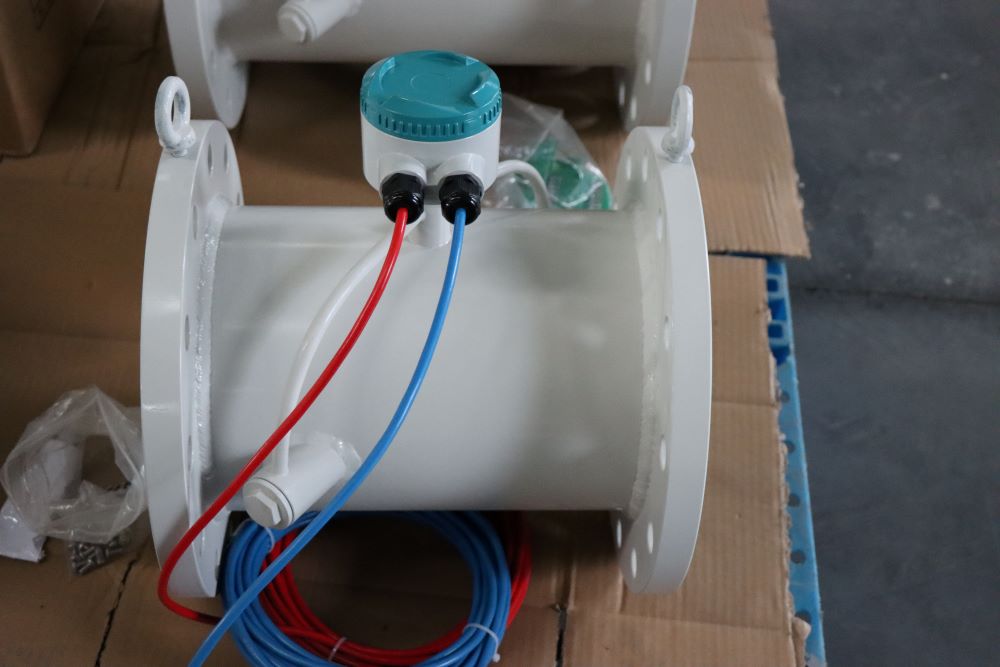

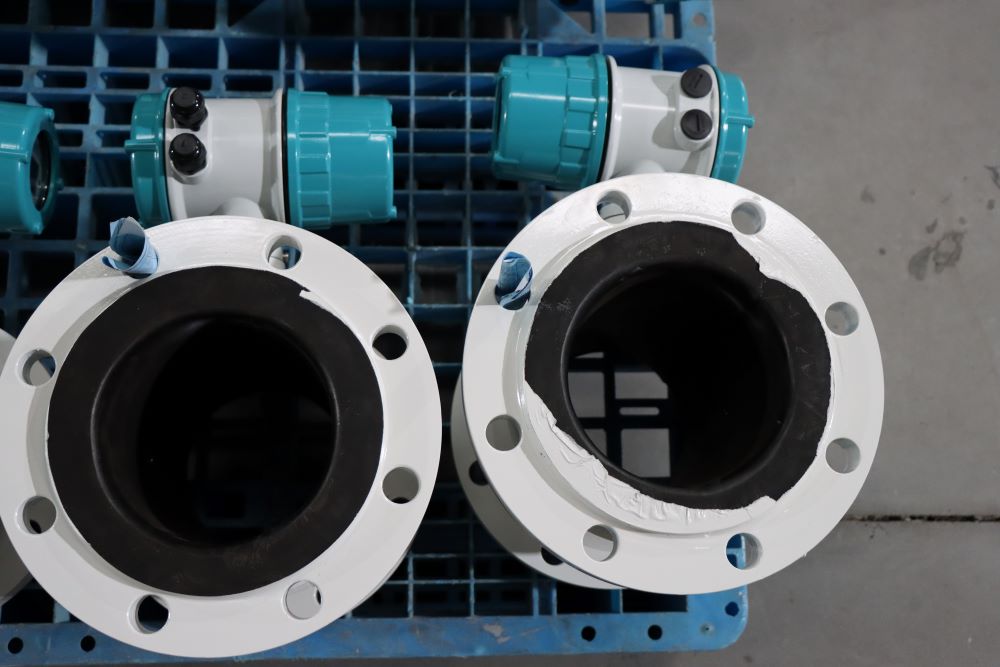

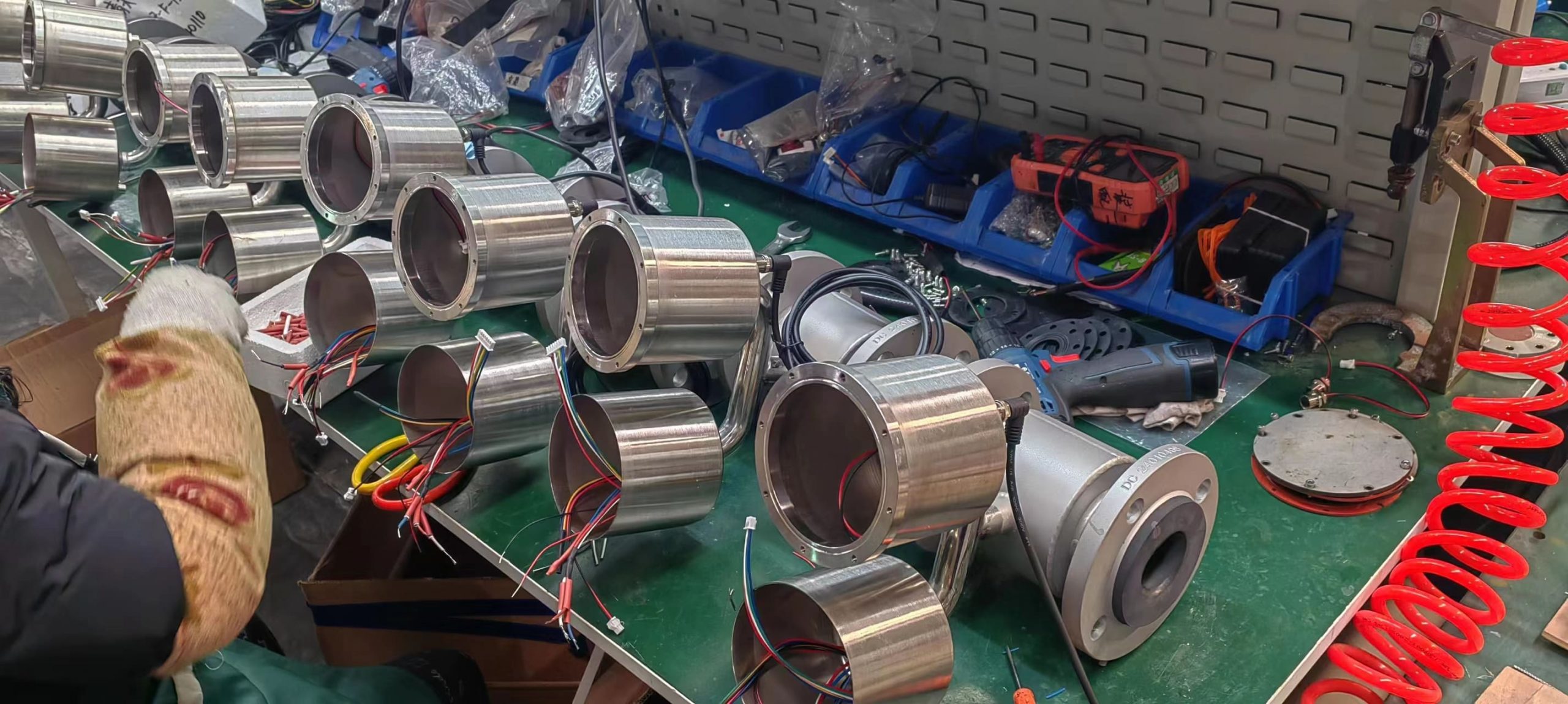

Electromagnetic flowmeter has flow sensor and transmitter two parts, sensor measuring tube is equipped with excitation coil, excitation current after the magnetic field through the measuring tube, a pair of electrodes installed on the inner wall of the measuring tube and liquid phase contact leads to induction potential, to the transmitter. According to the type of transducer and sensor assembly, there are two types: separation type and one type. In sewage treatment technology, large diameter flowmeters are mostly split, some are installed underground, and some are on the ground. The working principle of the electromagnetic flowmeter is based on Faraday’s law of electromagnetic induction. When the conductive metal rod moves at a certain speed perpendicular to the direction of the magnetic field line, an induced voltage is generated.

Now the function of the electromagnetic flowmeter on the market is also very different, simply can only measure one-way flow, can only output analog signals. The intelligent electromagnetic flowmeter has many functions such as bidirectional flow measurement, range switching, upper and lower limit flow alarm, air pipe and power cut alarm, small signal cutting, flow display and total calculation, active check and self-diagnosis of faults, communication with the host computer and motion configuration.

A prerequisite for the use of electromagnetic flowmeters is that the liquid to be measured must be conductive, and the measurement error will occur if the conductivity is lower than the threshold value, so it cannot be used, and even if the threshold value changes, it can be measured, and the indicating error changes little. Usually the conductivity of sewage is very high, because it contains many ions, which is also one of the advantages of electromagnetic flowmeters used to measure sewage.

Some characteristics of the electromagnetic flowmeter itself also determine that compared with other flowmeter products, it is more suitable for the measurement of sewage. The electromagnetic flowmeter has good stability, it is not affected by external factors such as temperature, pressure, viscosity, and no pressure loss caused by shortening or protruding inside the measuring tube. In addition, the initial signal detected by the flow element is a voltage that varies linearly with the average flow rate of the fluid, which is independent of other properties of the fluid.

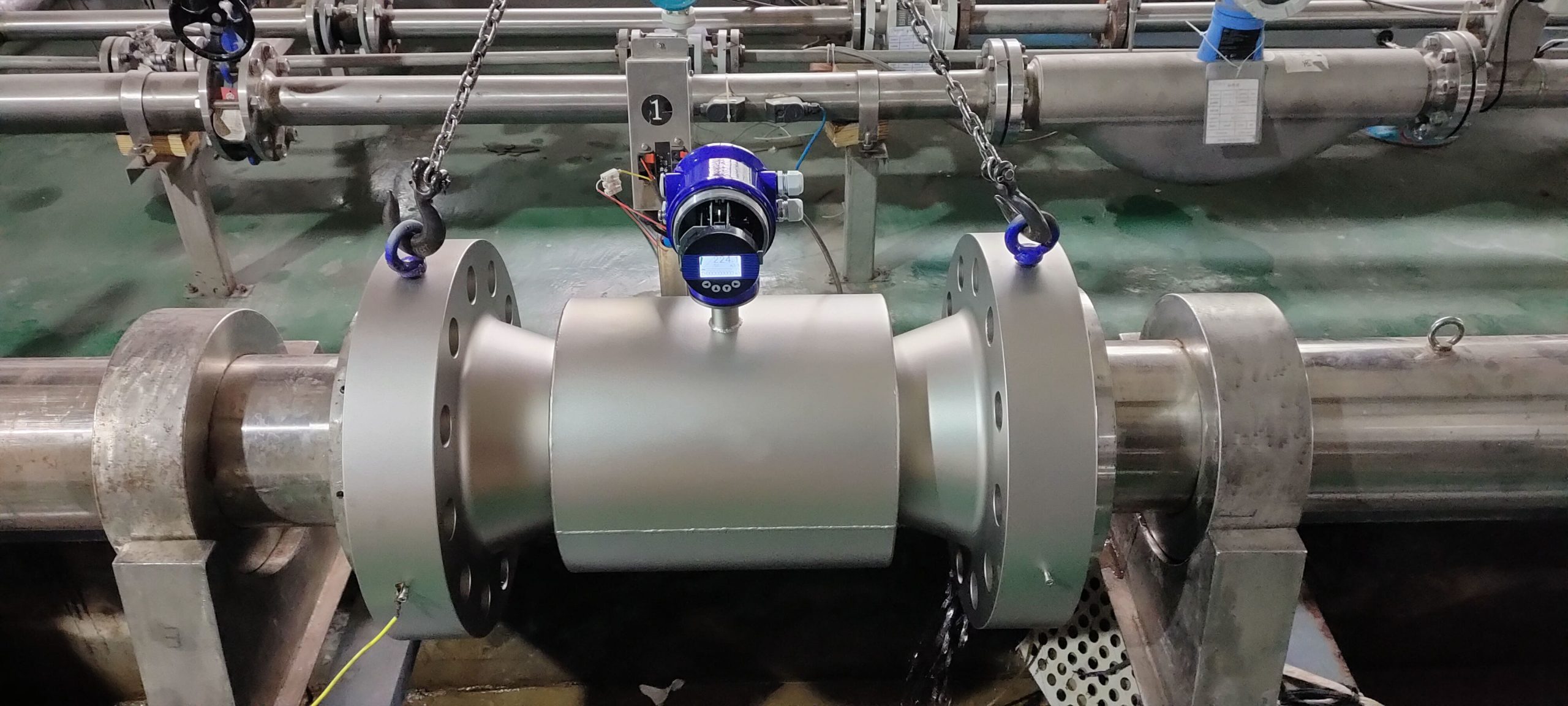

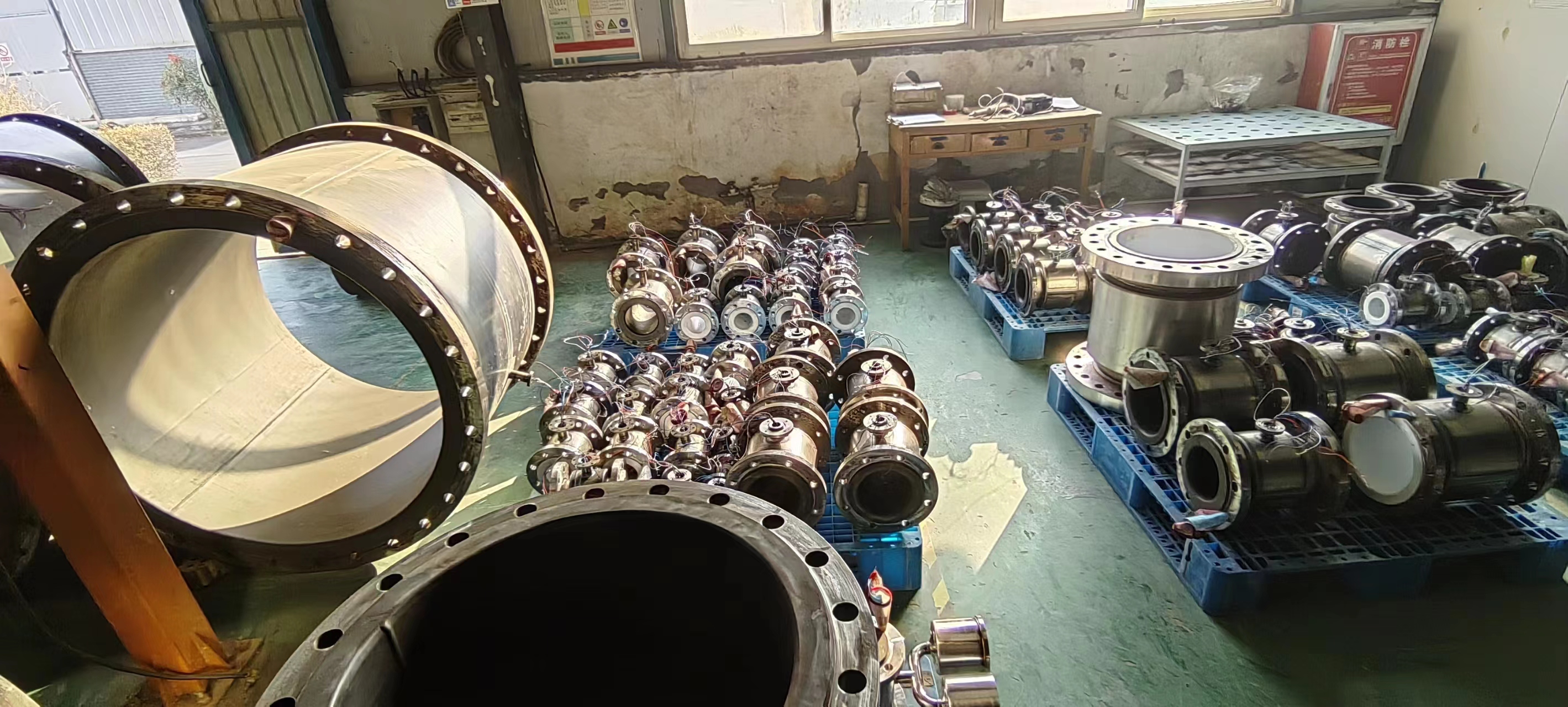

There is also the compact structure of the electromagnetic flowmeter, small size, installation, operation, protection are very convenient, the measurement system uses intelligent design, the overall sealing is good, and can work normally in a harsh environment. Compared with other flowmeter products, vortex flowmeter because of technical reasons, the caliber is difficult to make larger, ultrasonic flowmeter in the quotation relative to the electromagnetic lack of advantages, so in the sewage treatment industry, electromagnetic flowmeter, especially large caliber electromagnetic flowmeter has great advantages, and has been very common use.

-.jpg)

-.jpg)

-.jpg)