What factors can cause deviations in intelligent vortex flowmeters?

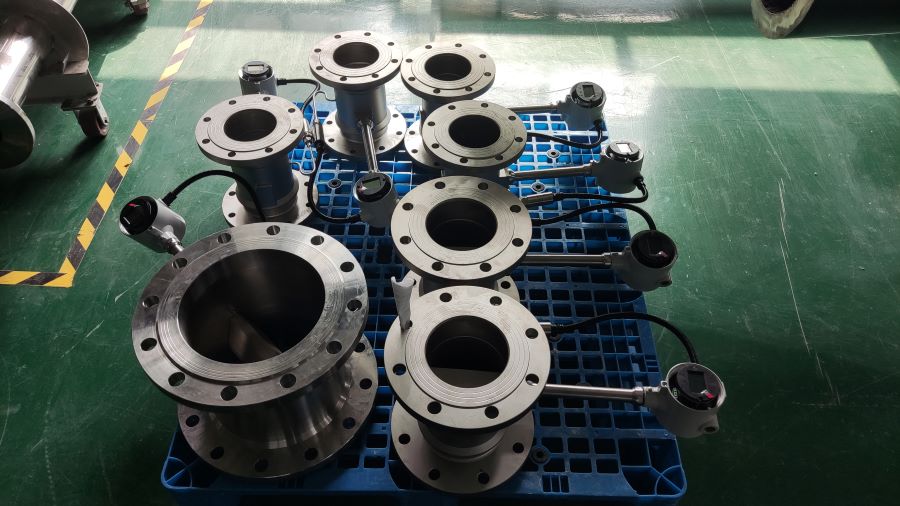

Vortex flowmeters are mainly used for flow measurement of industrial pipeline material fluids, such as gases, liquids, and steam. Due to the small pressure loss, wide range and high accuracy of vortex flow, it is almost unaffected by fluid density, pressure, temperature and viscosity when measuring working conditions. If a flow error is reflected in the use of a vortex flowmeter, the first thing to do is to distinguish this error, which leads to a flow deviation.

Vortex flowmeters are mainly used for flow measurement of industrial pipeline material fluids, such as gases, liquids, and steam. Due to the small pressure loss, wide range and high accuracy of vortex flow, it is almost unaffected by fluid density, pressure, temperature and viscosity when measuring working conditions. If a flow error is reflected in the use of a vortex flowmeter, the first thing to do is to distinguish this error, which leads to a flow deviation.

The harm of temperature to detection

Temperature can affect the measured materials of general flowmeters. It can influence the density, viscosity and other properties of the medium, causing incorrect or deviated measurement values. Eliminating this kind of danger is usually done to change the K-index. At present, some manufacturers’ flowmeters have modified the fixed temperature and real-time temperature in mobile phones.

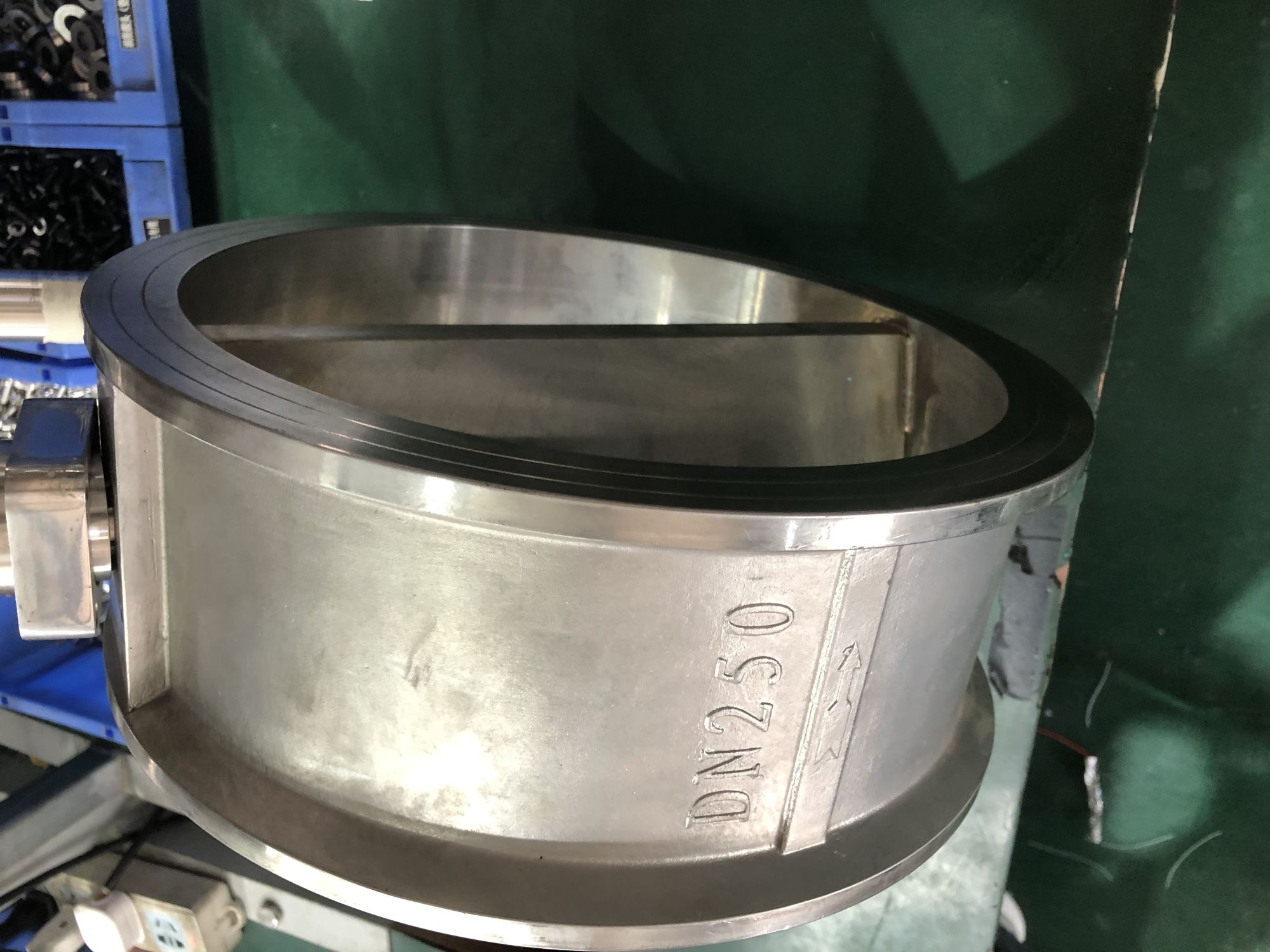

2. The inner diameter of the vortex flowmeter pipeline is inconsistent with that of the flowmeter

3. Selection difficulties

When making specific choices, the smallest possible specification should be selected to enhance measurement accuracy. For instance, in the construction of vortex pipelines, due to some equipment not being used at times, the specific usage flow rate decreases. In actual applications, the original design specification is chosen to be too large, which is equivalent to raising the measurement flow limit. The small flow label of the process pipeline cannot be guaranteed, and the flow rate can still be used if it is sometimes difficult to change. The change in process conditions is only temporary. The accuracy of the marking can be combined with the parameters.

4. The vortex in the vortex flowmeter causes harm to the area of the object facing the flow

If the liquid to be measured contains viscous particles, they may gradually accumulate on the flow-facing surface of the turbine generator, altering its geometry and specifications, and then changing the flow coefficient. Therefore, attention should be paid to cleaning during use.

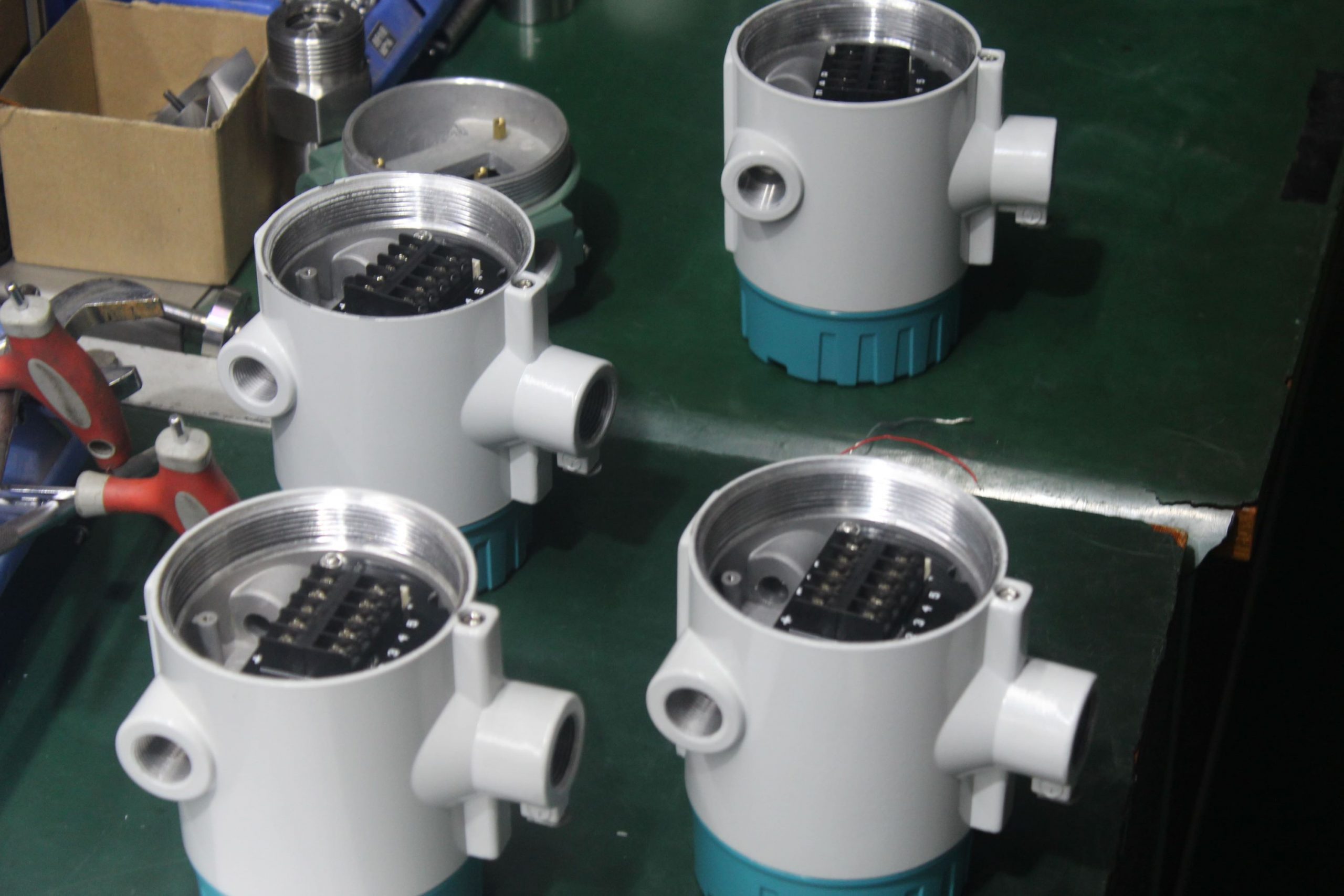

5. Assembly issues

The length of the straight pipe section in front of the vortex flowmeter sensor is usually an assembly issue. If the length is insufficient, it will endanger the measurement accuracy.