Installation precautions for vortex gas flowmeters

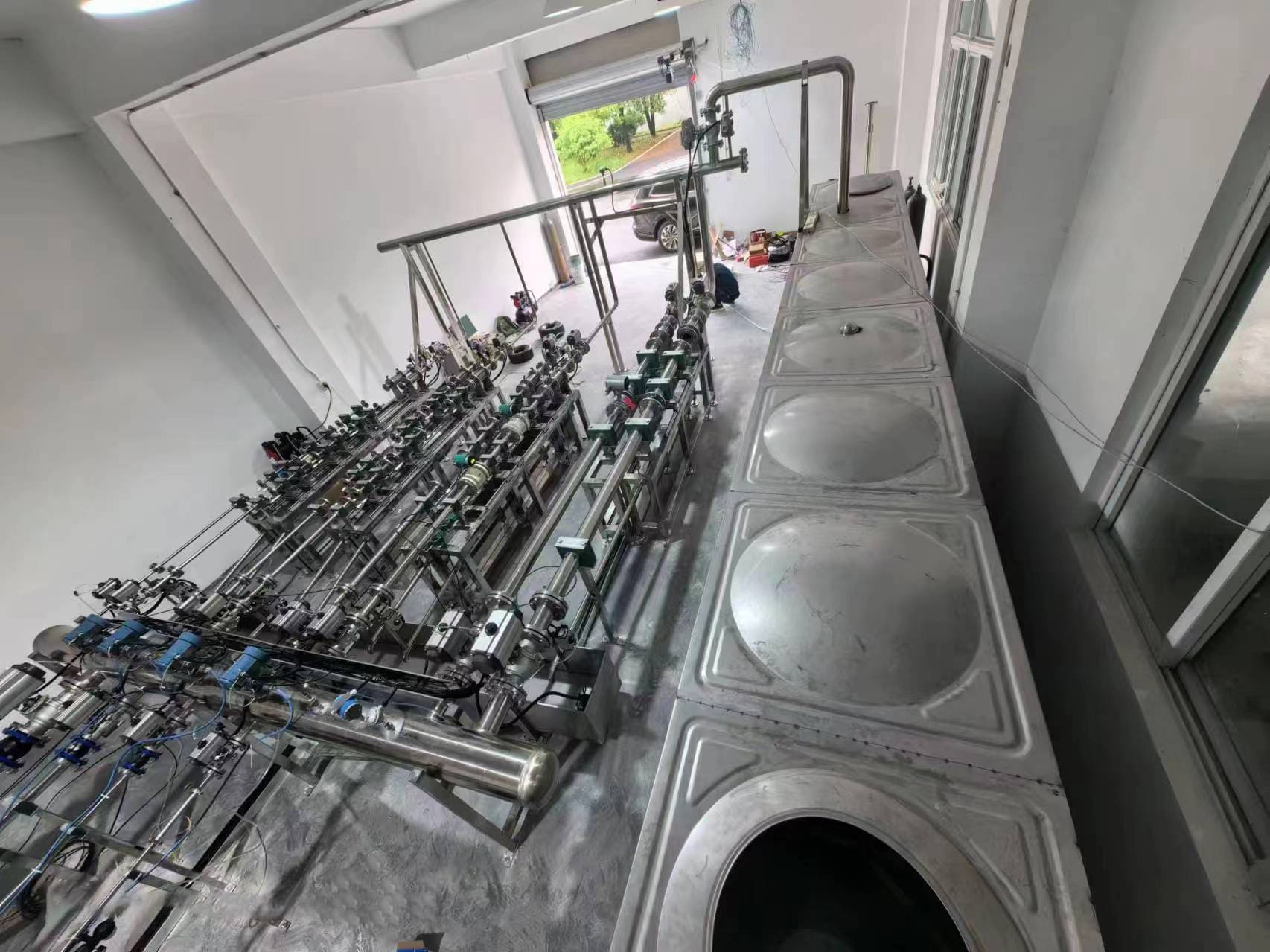

Gas flowmeters should be installed indoors as much as possible. If they are installed outdoors, measures should be taken to avoid direct sunlight and prevent rain.

2. Flowmeters should be avoided from being installed in places with strong magnetic field interference, small space and inconvenient maintenance and management.

3. Flowmeters should be installed in places with high temperatures, equipment radiation temperatures or containing corrosive gases. If flowmeters need to be installed, heat insulation and ventilation measures should be taken.

4. Flowmeters should be avoided from being installed on pipelines with mechanical structure vibration. If installation is necessary, effective shock absorption technical measures must be taken, such as adding flexible hoses for transition, or installing pipelines without fixed support points at 2DN upstream and downstream of the flowmeter and adding shock-absorbing pads.

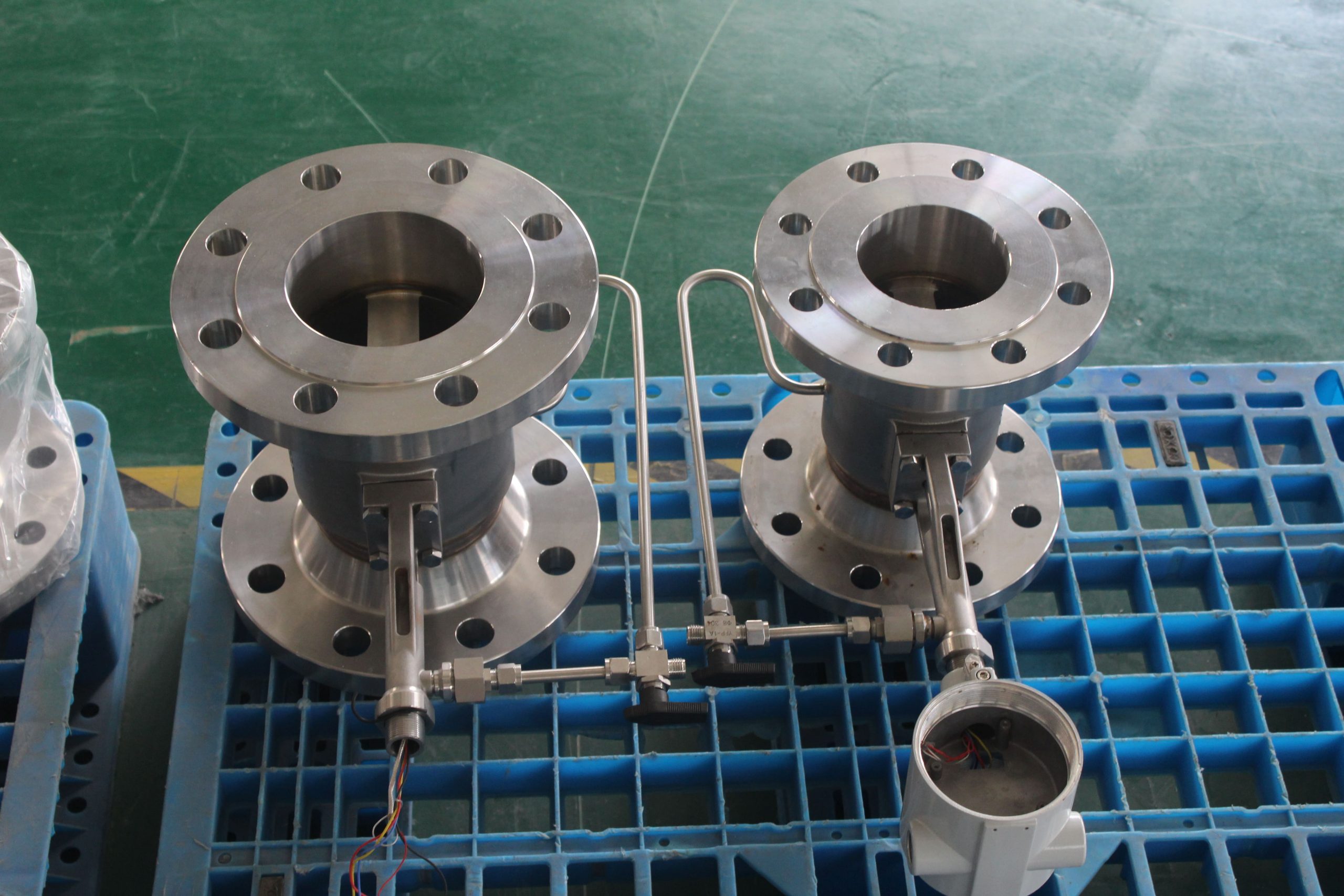

5. After the flange and pipeline are positioned by spot welding, the flowmeter should be removed. Welding with the flowmeter is not allowed.

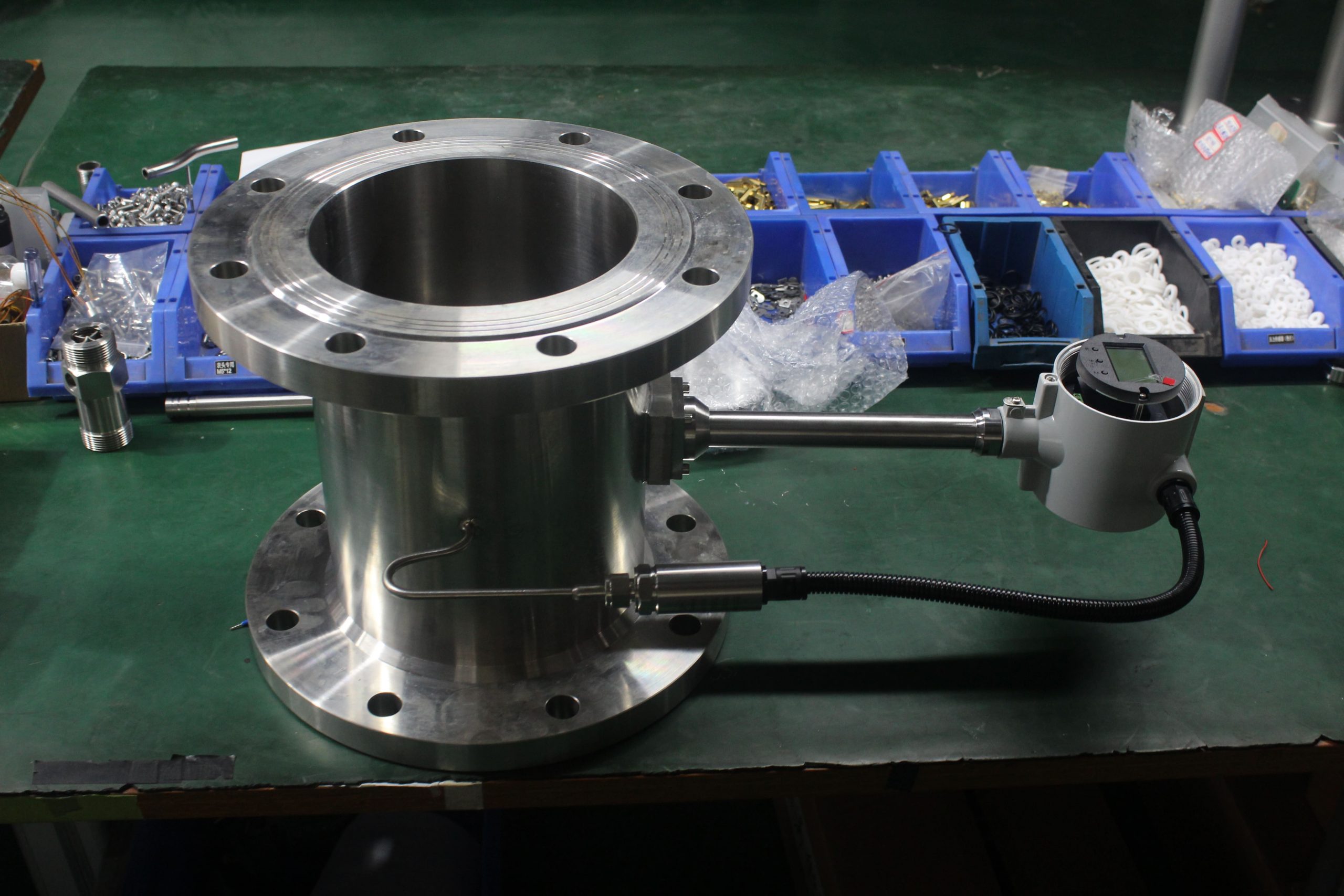

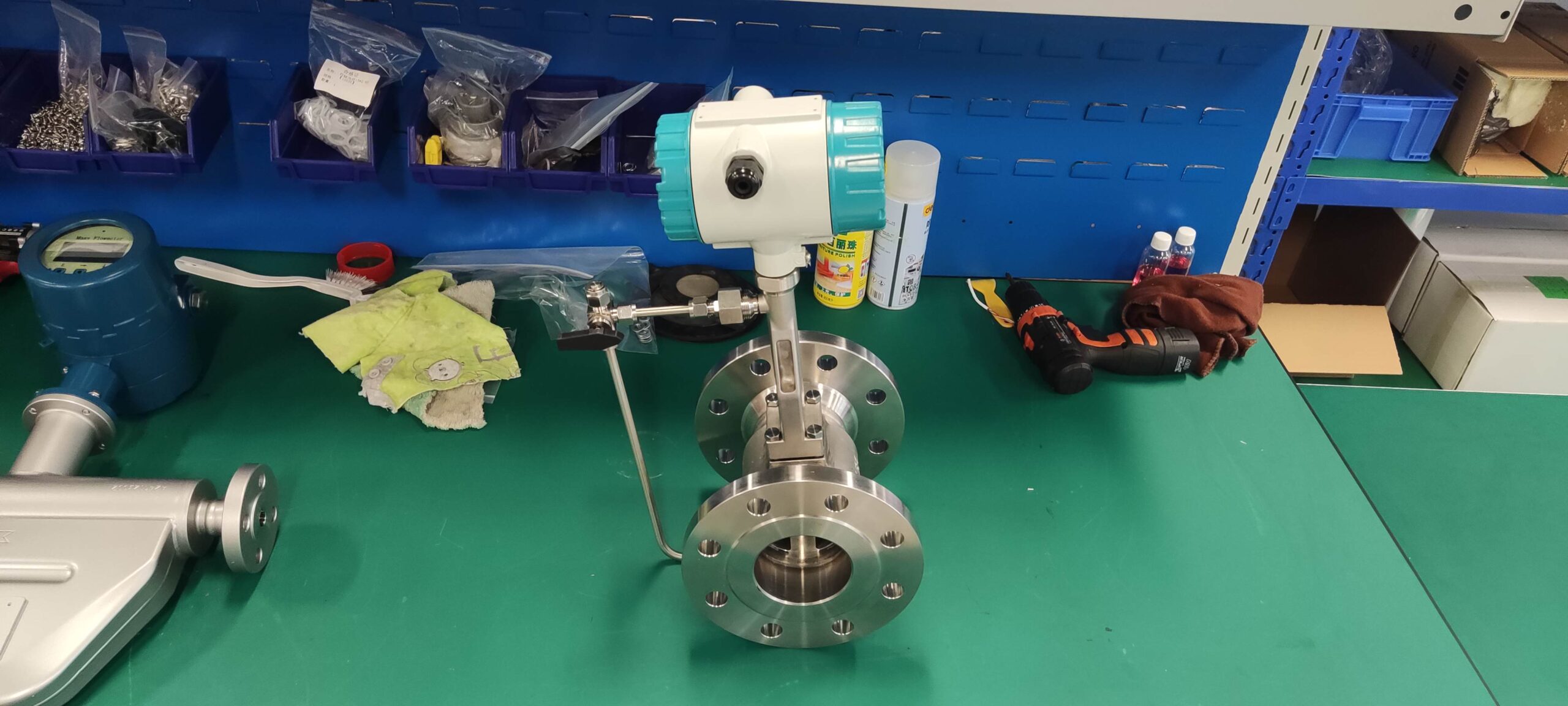

6. The flowmeter can be installed at any position 360° along the vertical axis of the pipeline. Installation method: In low-temperature medium, the rods are installed vertically on the ground; in high-temperature medium, the rods are installed parallel on the ground.

7. If the sagging of the pipeline is prone to cause leakage in the sealing system between the mass flowmeter and the flange, the flowmeter should be avoided from being installed on a long overhead pipeline as much as possible. If installation is required, the pipe support points must be set at 2 dN upstream or downstream of the flowmeter respectively.

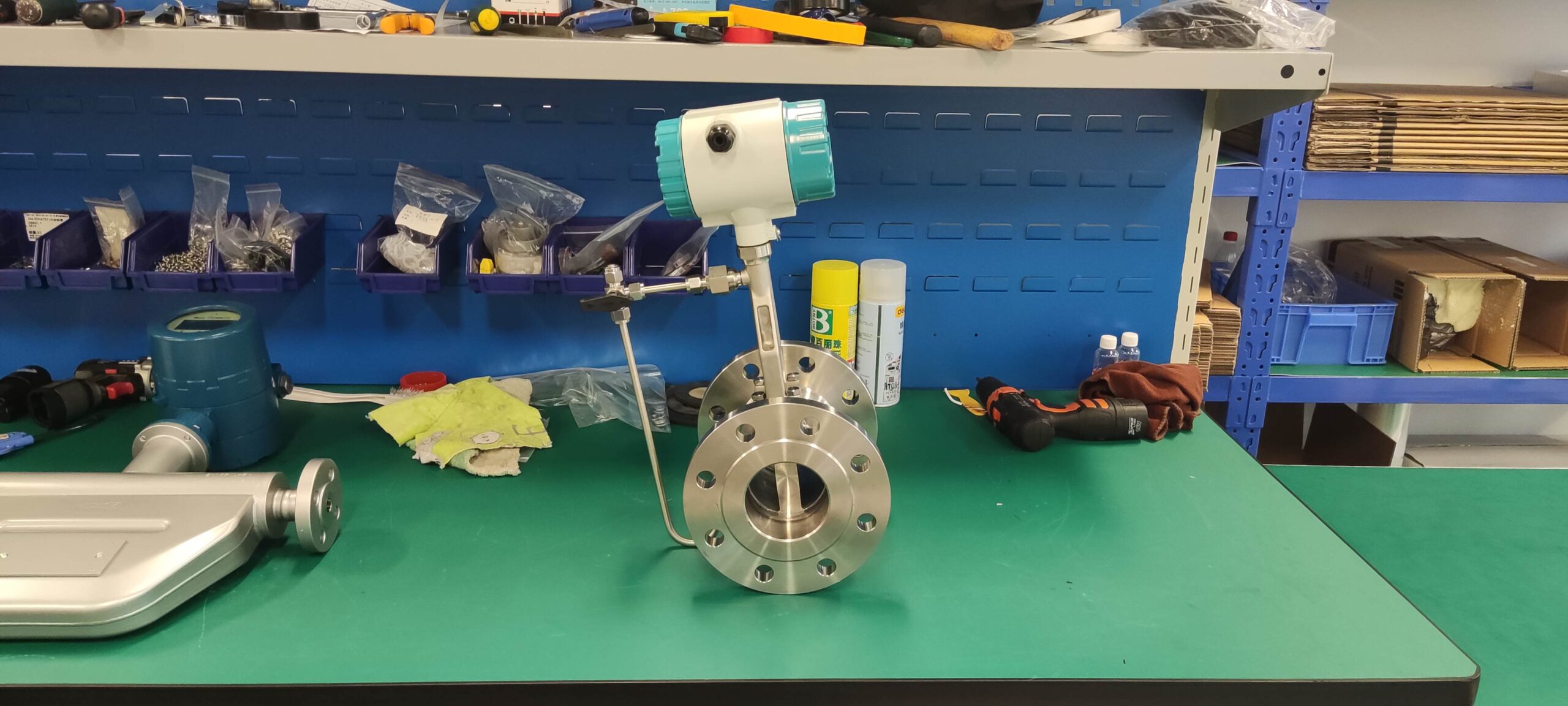

8. In the pipeline for measuring steam, to prevent the temperature requirement of the converter from being too high, at least half of the instrument connection rod should not be insulated.

9. To facilitate observation and wiring, the instrument head of the flowmeter can be rotated 360 ° to its original position. After adjusting the position, tighten the lock nut. In order to prevent water vapor from entering a shell through the lock nut, if necessary, the lock nut should be wrapped and sealed well with waterproof tape.

10. The direction of connecting the shielded cable of the gas vortex flowmeter should be far away from places with strong electromagnetic field interference. It is absolutely not allowed to be laid together with high-voltage cables. The shielded wire should be shortened as much as possible and must not be coiled to reduce the distribution of the enterprise and inductance. The maximum working length should not exceed 500 meters.

11. Unscrew the back cover of the watch case and send out the signal cable through the waterproof connector. Tighten the waterproof joint and ensure that the system cables must be bent downward before entering a waterproof joint to prevent water from flowing into the housing along the cables.