The inaccuracy of ultrasonic flowmeters may be due to these reasons

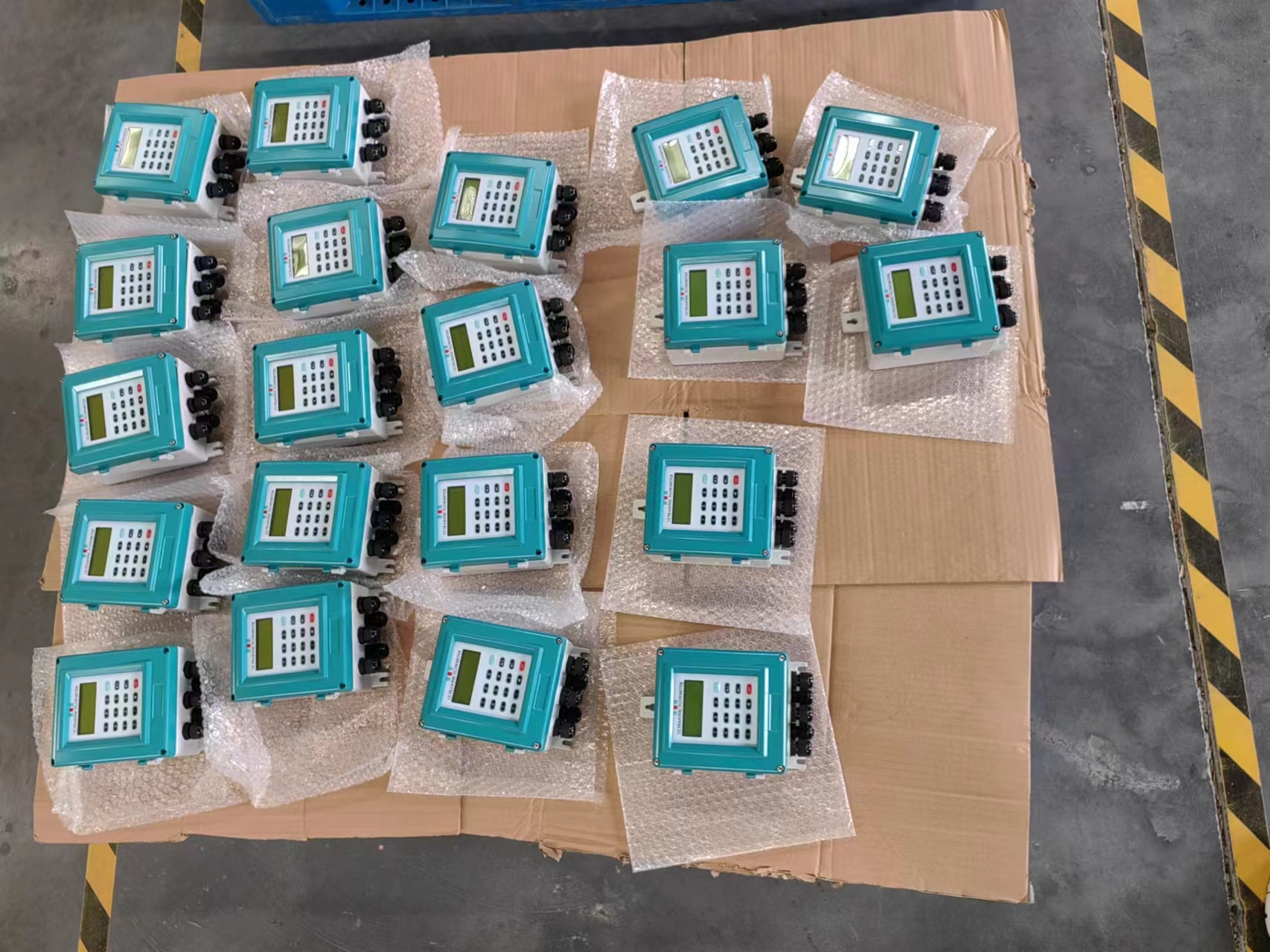

Ultrasonic flowmeters are flowmeters that measure flow by detecting the effect of fluid movement on ultrasonic beams (or ultrasonic pulses). Ultrasonic flowmeters can all be installed outside the pipe and measure flow in a non-contact manner. Their surface cost is basically independent of the size of the pipe diameter being measured, making them excellent instruments for measuring the flow of large pipes.

The reasons for the inaccuracy of ultrasonic flowmeters

It might be a problem with the probe equipment. On the contact surface between the probe and the pipe, due to rust spots and paint on the pipe surface, the signal reception is affected. Or the coupling agent between the probe and the contact surface is not evenly coated, with bubbles present and insufficient contact, which will cause defects such as no indication on the surface. Mostly on horizontal pipe sections, the transmitter equipment is higher than the positive and side lines on the side of the pipe. This is simply affected by the sediment at the bottom of the pipe and the bubbles at the top of the pipe, causing signal distortion and resulting in inaccurate indication values and other disadvantages.

2. Issues regarding the selection of measurement points. Some measurement points are selected in vertical or horizontal pipe sections where pressure is low and the medium is not fully filled. This can cause signal loss or weakening, resulting in disadvantages such as incomplete or no flow indication. Some measurement points are selected at locations with pumps, control valves or elbow sections of the casing. The lengths of the upper and lower straight pipe sections do not meet the requirements, resulting in unstable flow conditions of the medium. This will cause disadvantages such as inaccurate surface flow indication and unstable readings. If the measurement points are selected on pipelines with corrosion or rust spots inside, the measurement signal will be distorted and the flow cannot be measured.

3. Issues regarding the connection of the transmitter cable of the ultrasonic flowmeter. When it is assumed that the transmitter has an upstream transmitter and a base transmitter, they should be connected by two cables. If the equipment is reversed, the measured flow will be opposite, resulting in a negative flow indication value.

Perhaps there is a problem with the data Settings. Sometimes, due to the inaccurate supply of some technical parameters of the pipeline, this will lead to disadvantages such as inaccurate flow indication, or being too large or too small.

In conclusion, the problems with the numerical values presented by ultrasonic flowmeters are caused by multiple factors. Careful investigation is still needed to identify the real issue. If you encounter any other questions regarding the use of ultrasonic flowmeters, you can contact us online or by phone at any time.