Ultrasonic flowmeter common faults and solutions

Ultrasonic flowmeter in the use of the following faults, we can according to the method given in the article to solve.

1, if the flow meter does not appear after starting, it is necessary to check whether the fuse is burned, and the power supply is not used properly.

2. If no characters appear after the instrument is turned on, it may be that the program chip is in doubt and needs to be repaired.

3, if it can not work under the field strong disturbance, it is necessary to stay away from the frequency converter and strong magnetic field disturbance as far as possible to ensure a stable power supply and good grounding.

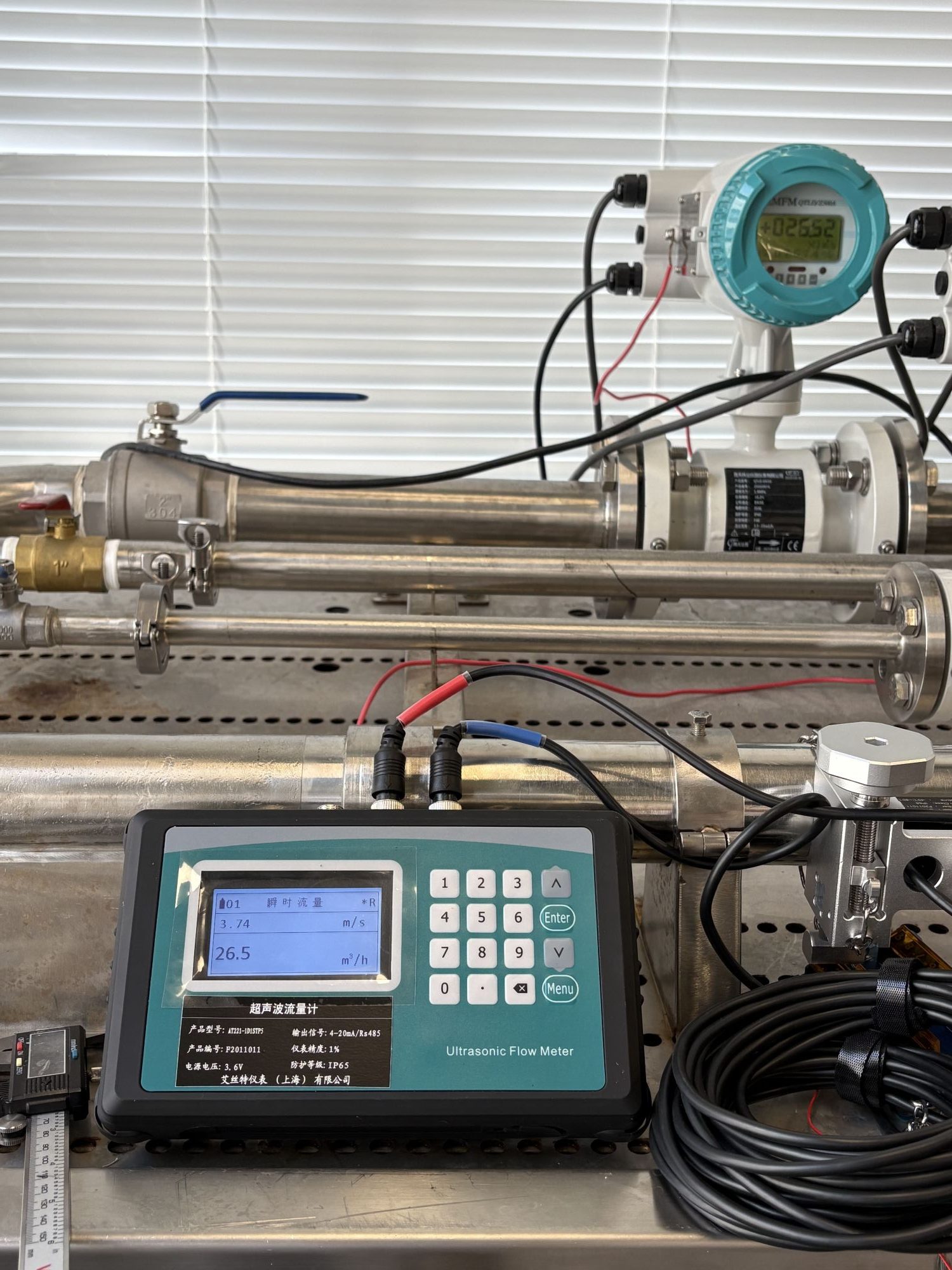

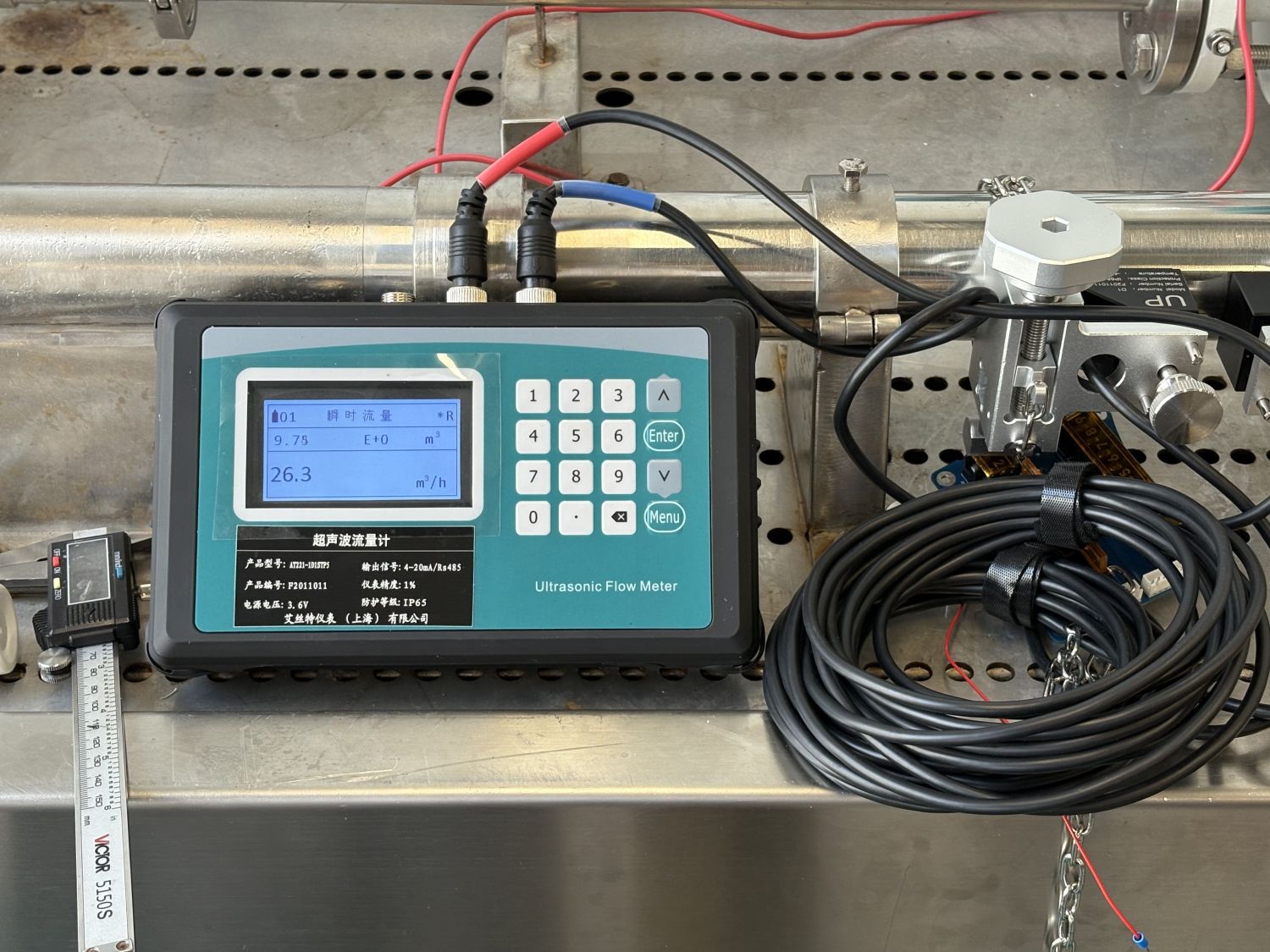

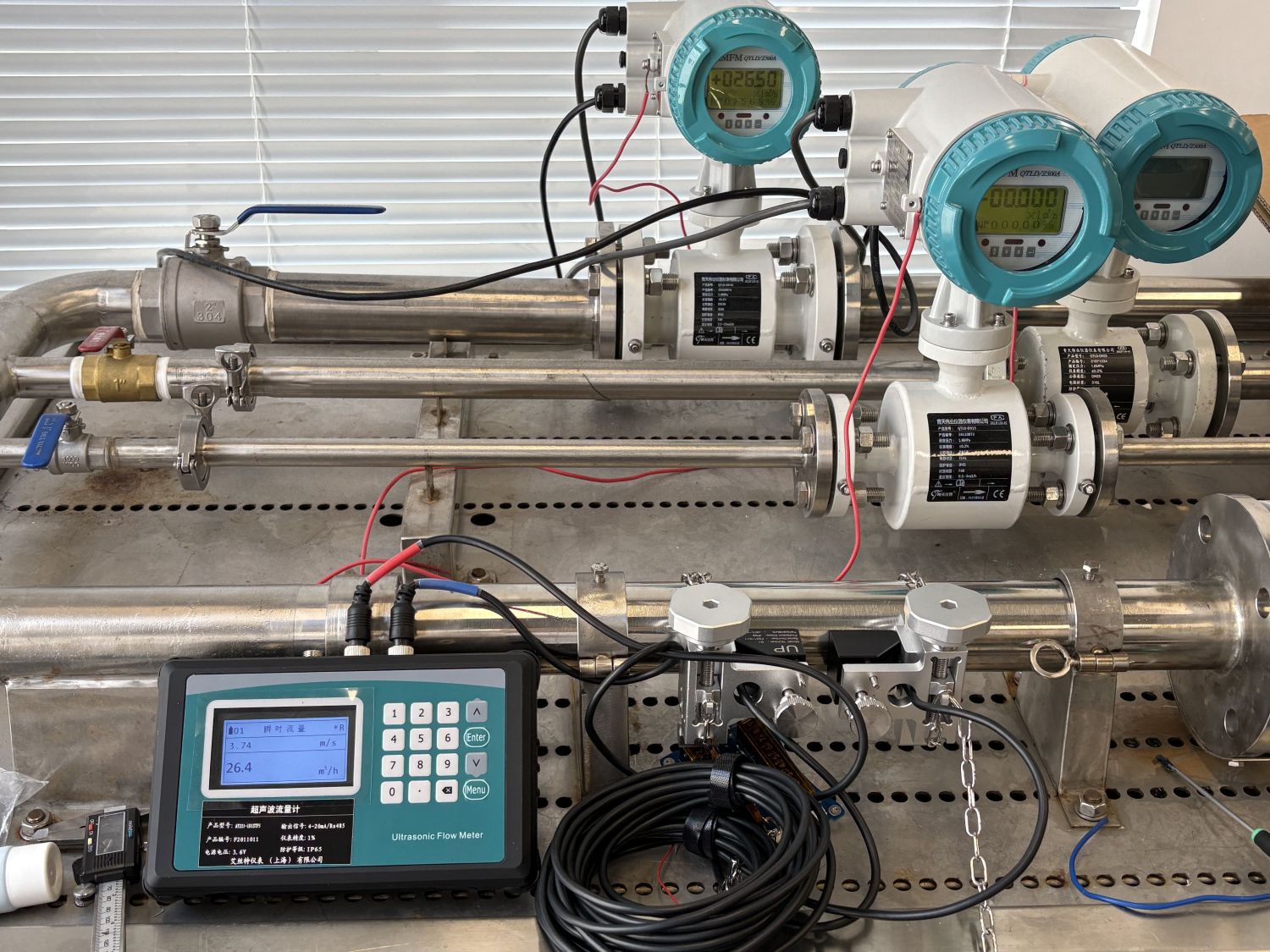

4, when the instantaneous flow meter is shaken, it may be caused by factors such as signal strength shaking or measurement fluid shaking. It can first adjust the probe orientation, improve the signal strength, and perhaps select the measurement point from scratch to ensure the working conditions of the first 10D after 5D.

5, the outer clamp flowmeter pipe diameter is too large, the pipe scaling is severe, mainly because the device method is wrong. Choose a piercing probe, or choose a “Z” device method.

6, the probe signal of the piercing ultrasonic flowmeter may reduce the thickness of the surface scale, then the orientation of the probe needs to be adjusted, and the probe emission surface of the surface scale is clean.

1. Clean the pipeline area where the sensor is to be installed during installation to expose the original luster of the metal;

2. The shielded wire of the ultrasonic signal cable can be suspended and not connected, and do not short circuit with the positive and negative electrode (red and blue wire);

3, after the sensor is connected, fill with sealant (coupling agent) to prevent water;

4. After the sensor is filled with sealant and covered, the sensor shielding wire is put into the wire hole and screwed tightly to prevent water;

5, when binding the sensor, the fixture (stainless steel belt) should be fixed in the center of the sensor, so that the force is uniform, not easy to slide;

6. The contact part of the sensor and the pipeline should be coated with enough coupling agent around it to prevent air, dust or rust from entering and affecting the transmission of ultrasonic signals.