How to install the external clamp-on ultrasonic flowmeter probe correctly

When installing the probe of the external clamp-on ultrasonic flowmeter, it is advisable to select the part with the finest pipe material as much as possible. The equipment area outside the pipe must be clean, and the rust and paint on the pipe surface need to be removed. If conditions permit, use a grinding machine to smooth and polish it, and then use a clean cloth dipped in acetone or alcohol to wipe off the oil stains and dust Next, apply a satisfactory coupling agent to the central part of the probe and the tube wall.

When the pipe is very thick or due to the presence of suspended solids in the liquid, excessive scaling on the inner wall of the pipe, or excessive thickness of the material, the signal of the V-method equipment is weak and the machine cannot operate normally, the Z-method equipment should be selected. The reason is that when using the z method, ultrasonic waves are directly transmitted in the pipeline without refraction (referred to as monophonic path), and the signal attenuation is small. The z method can measure pipe diameters ranging from 100mm to 6000mm. When measuring the flow rate of practical equipment, it is recommended that the z method be adopted for pipes larger than 200mm (this way, the measured signal will be larger).

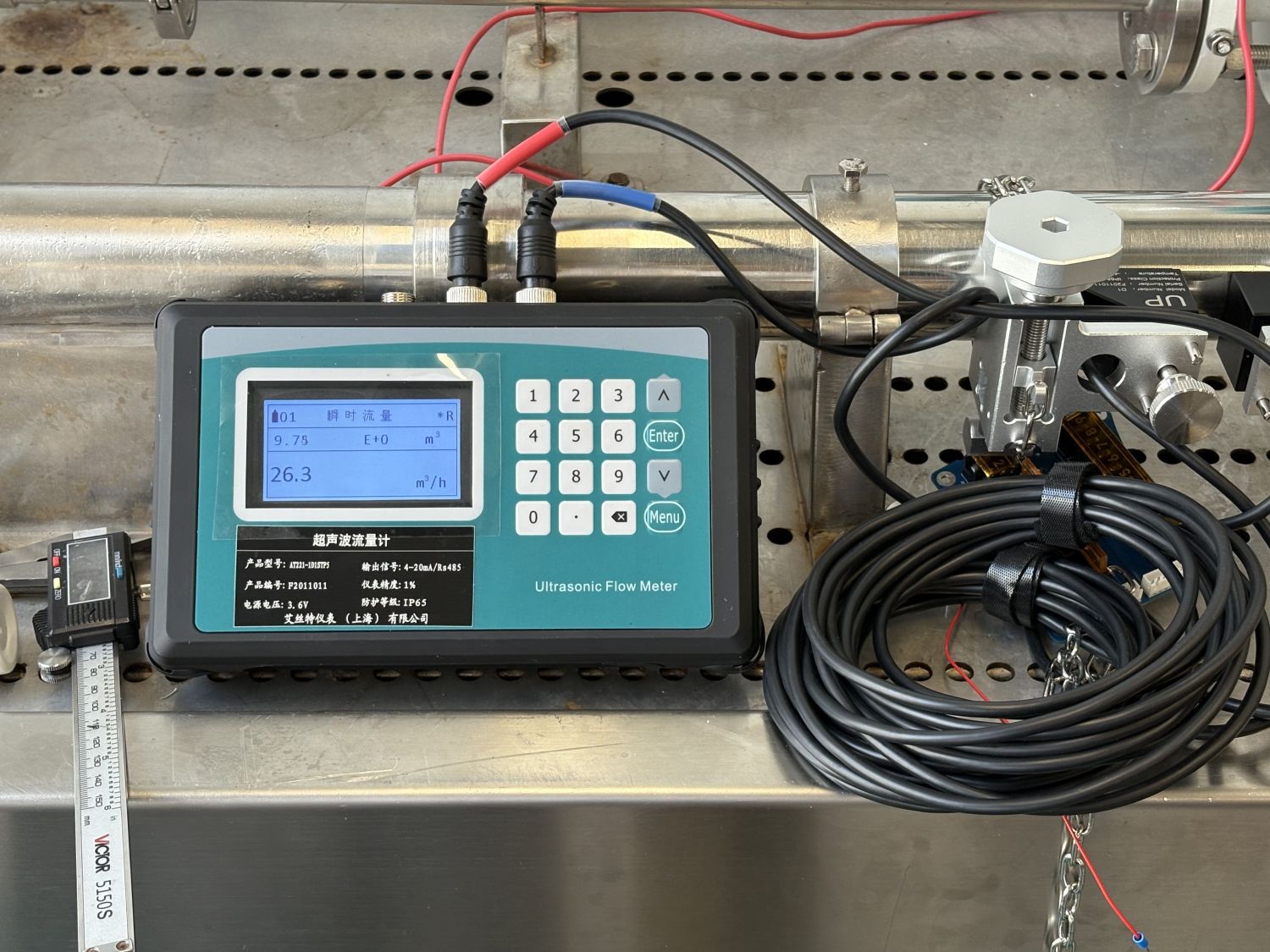

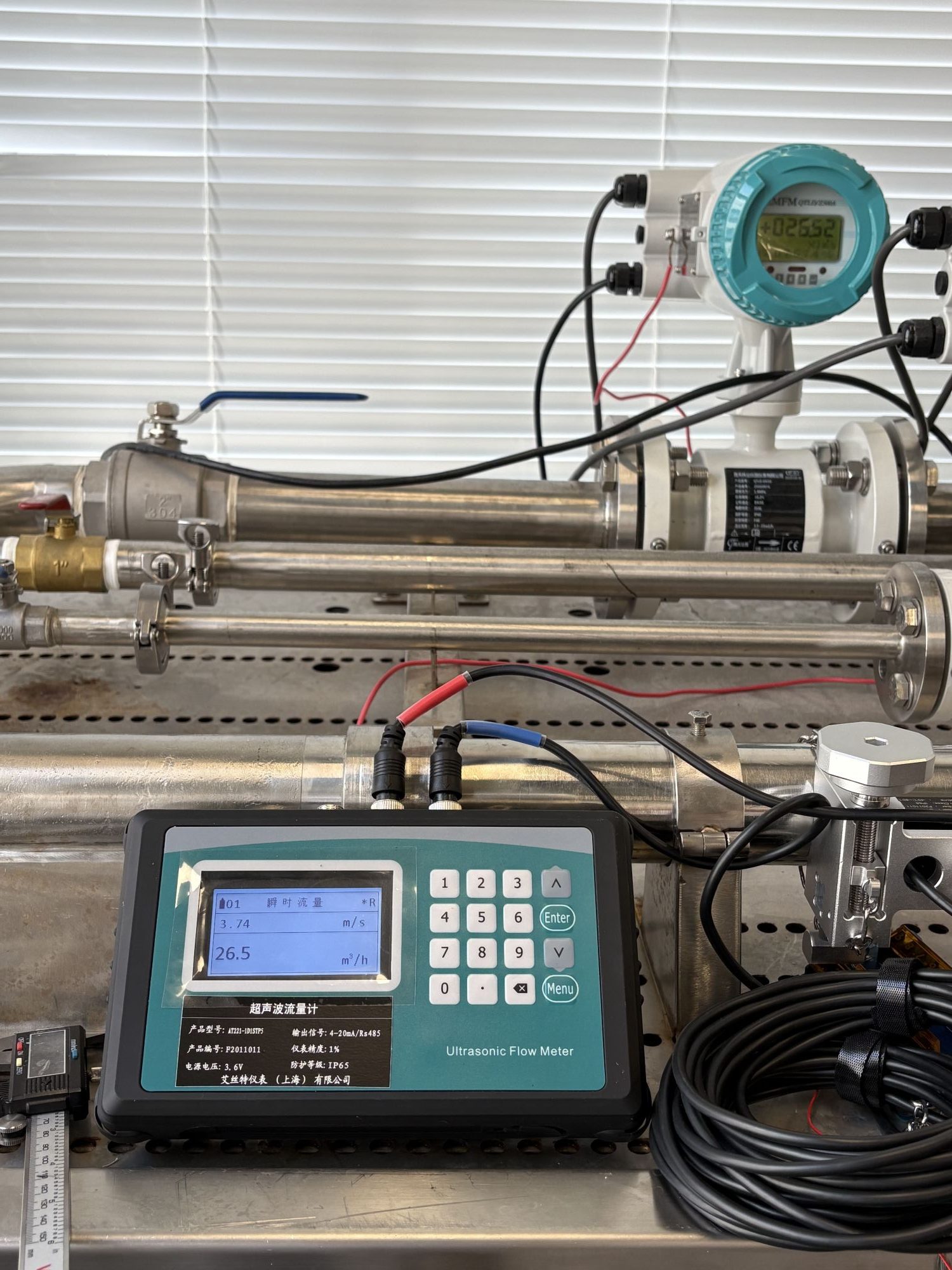

Although in most cases, simply applying a coupling agent to the probe and attaching it to the outside of the pipe wall can achieve measurement results, it is still necessary to choose the correct and cautious operation method. The following checks must be carried out to ensure the best measurement results and the long-term reliable operation of the flowmeter. The operation to verify whether the external clamp-on ultrasonic flowmeter is normal and reliable includes: the greater the signal strength and the higher the signal quality q value, the more reliable the flowmeter can operate for a long time, and the higher the credibility of the displayed flow value.

If the electromagnetic interference in the environment is too strong or the received signal is too low, the credibility of the displayed flow value will be poor, and the possibility of long-term reliable operation will be small. When installing the external clamp-on ultrasonic flowmeter, there must be no air bubbles or sand particles between the probe and the pipe wall. If the operation is not carried out in accordance with the specifications, it will seriously affect the measurement effect. On the horizontal pipe section, the probe should be installed on the horizontal axis of the pipe cross-section to prevent air bubbles from existing in the upper part of the pipe. Assuming that the probe cannot be installed horizontally symmetrically due to the address space of the equipment, it can be installed vertically or at an Angle under the condition that there are no air bubbles in the upper part of the pipe.