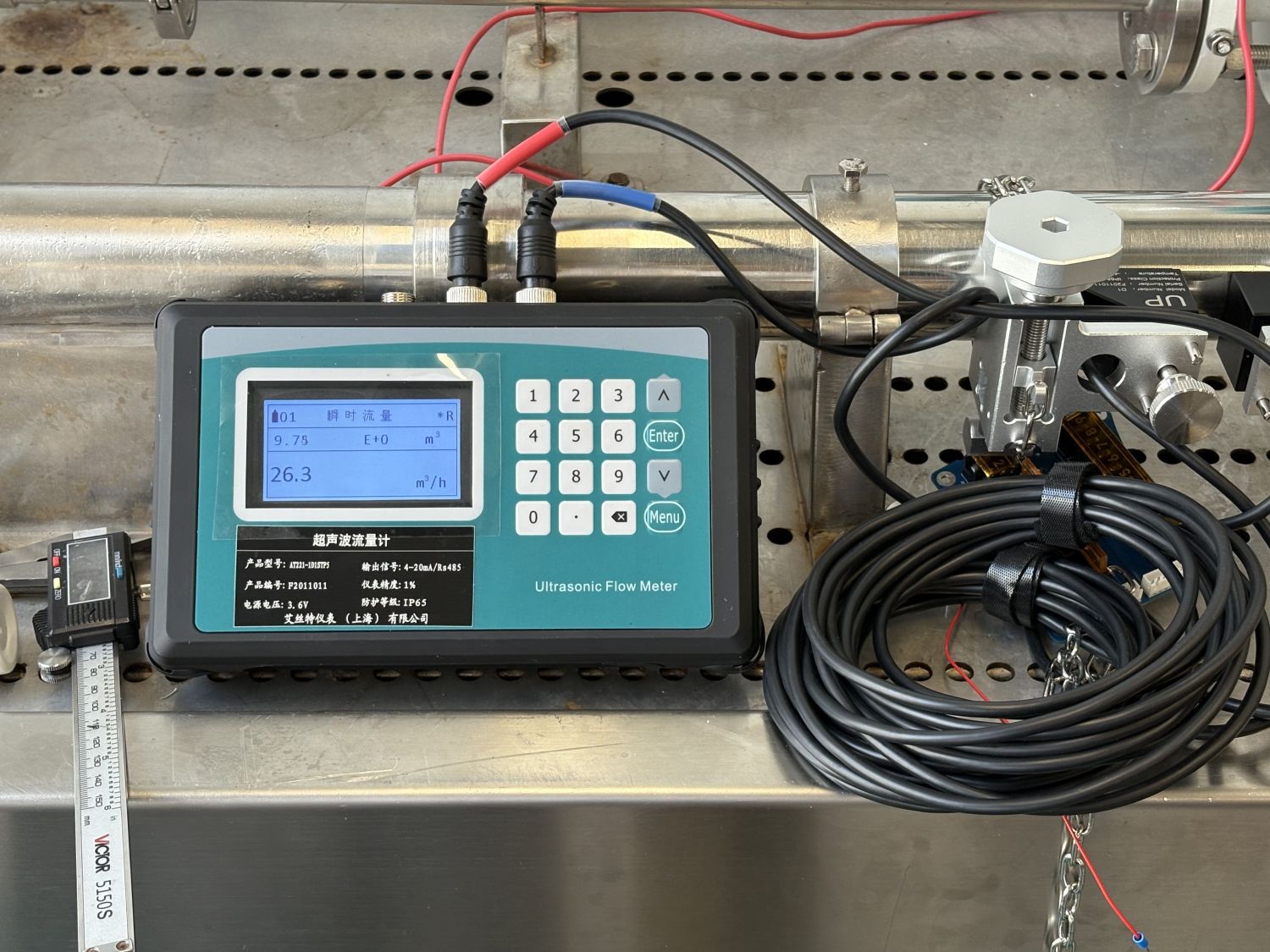

Common fault situations in the practical application of ultrasonic flowmeters

Today, we mainly talk about several common fault situations of ultrasonic flowmeters and the corresponding solutions.

1. Signal loss

When using an ultrasonic flowmeter, the problem of signal loss may be encountered. Signal loss refers to the inability to receive sufficient signals from the sensor, resulting in the inability to measure flow velocity and volume. This situation is usually caused by the presence of obstacles or dirt between the sensor and the measured medium. The solutions include cleaning the surface of the sensor, checking whether the installation position of the sensor is blocked and repairing the obstacles.

2. Inaccurate measurement

Sometimes, the measurement results of ultrasonic flowmeters may not match the actual situation, that is, the measurement may be inaccurate. The reason for this situation might be the change in the properties of the fluid medium, such as variations in temperature and pressure. In addition, equipment aging, sensor damage or incorrect calibration may also lead to inaccurate measurements. To solve this problem, it is necessary to carry out regular maintenance and inspection of the equipment, replace aged parts, and ensure accurate calibration operations.

3. Frequency drift

Frequency drift refers to a certain deviation between the frequency of the output signal of an ultrasonic flowmeter and the set frequency. This kind of malfunction is usually caused by unstable power supply voltage or the influence of the working environment of the equipment. The solutions include adjusting the power supply voltage, optimizing the working environment of the equipment, and inspecting and repairing the equipment circuit.

In practical applications, ultrasonic flowmeters may encounter some fault situations, such as signal loss, inaccurate measurement and frequency drift, etc. The causes of various faults are complex and diverse, but they can usually be solved by cleaning the sensors, regular maintenance and inspection, replacing aged parts, correct calibration, and optimizing the working environment of the equipment. Maintaining the normal operating condition of the equipment is crucial for accurately measuring the fluid flow velocity and volumetric flow rate.