The adverse effects of ultrasonic flowmeter sensors on equipment

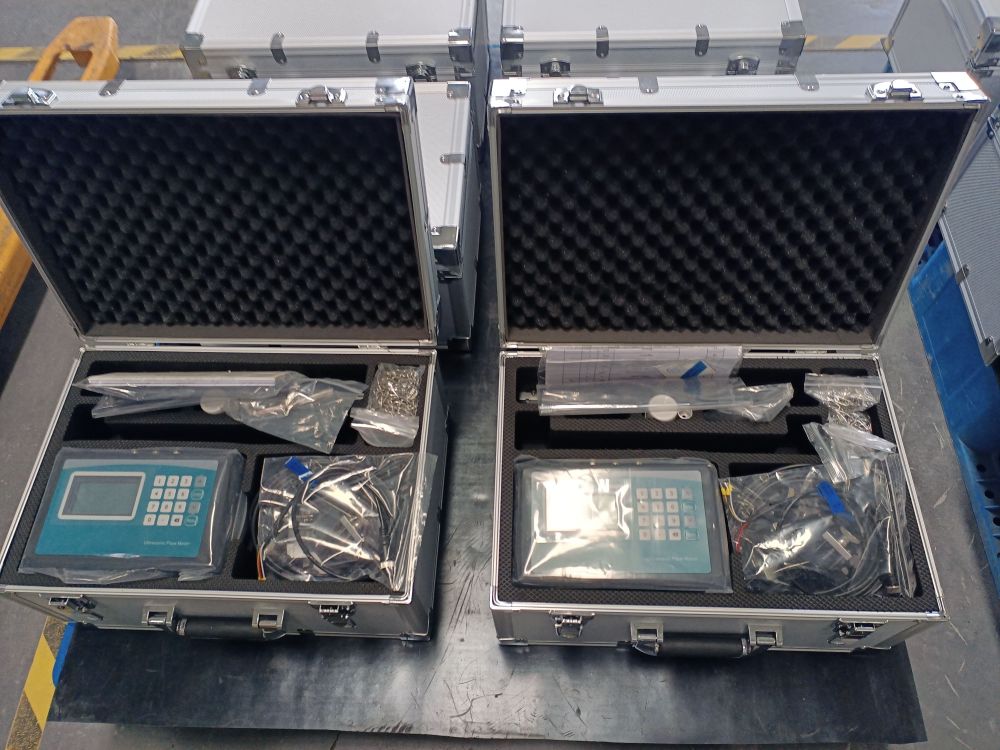

Ultrasonic flowmeters, as very important flow measurement devices in various industrial fields, have a particularly significant adverse impact on measurement accuracy due to their sensors. Different types of sensors should be selected based on the differences in application environments. Today, Aister Instruments, a flowmeter manufacturer, will provide the following explanations regarding several different sensors.

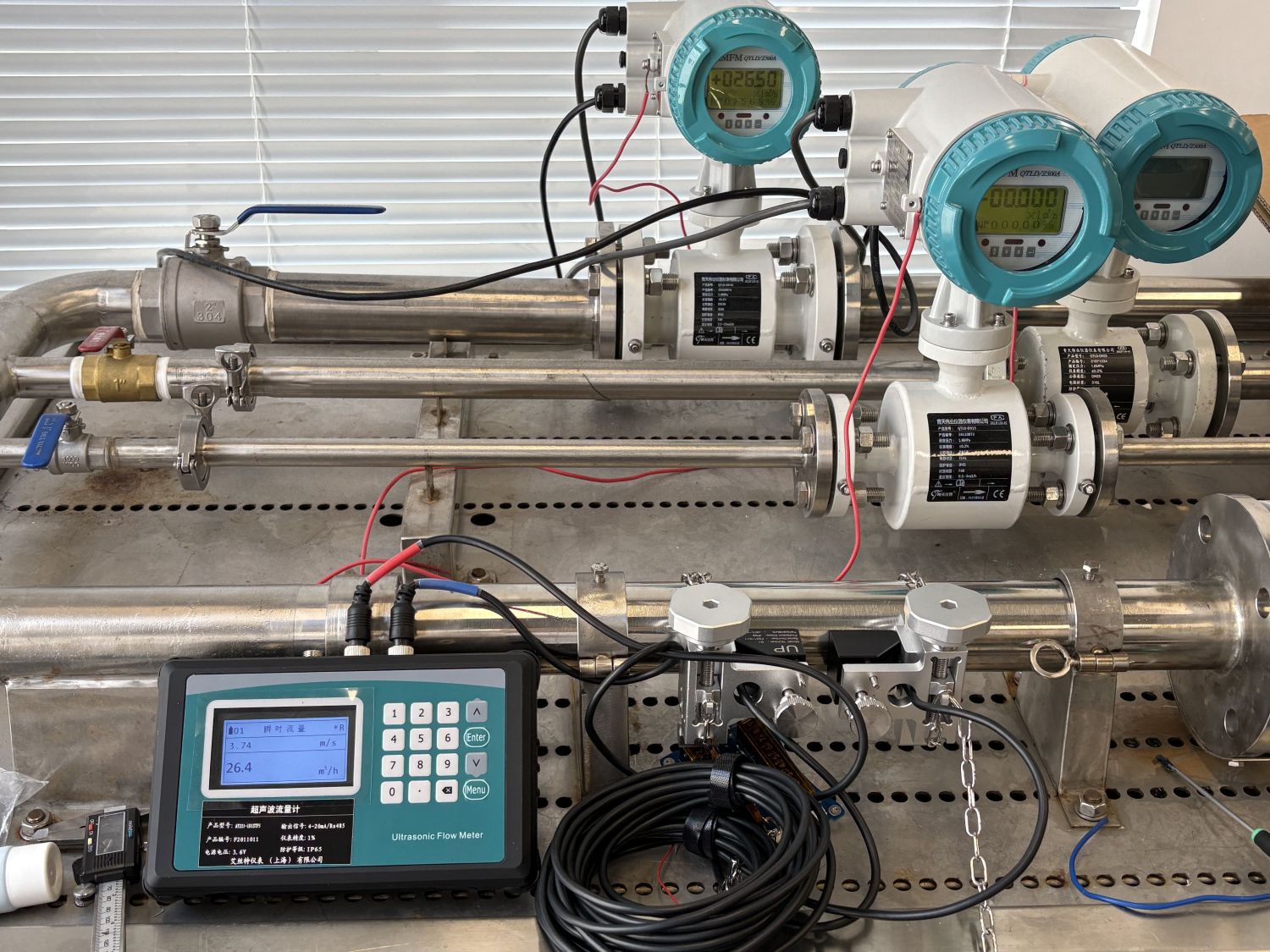

1. Clamp-on ultrasonic flowmeter sensor

When the ultrasonic flowmeter adopts this installation form, the outer wall of the flow detection must be cleaned as a whole and polished smooth. Then, a coupling agent is used to fix the probe on the outside of the polished position. The reason for using the coupling agent is that it does not adversely affect the ultrasonic imaging and is not corrosive to the probe. However, by choosing this method, Improper handling of the coupling agent may cause detection errors.

2. Insertable ultrasonic flowmeter sensor

When using this method for ultrasonic flowmeters, holes need to be made at the detection site, and then the probe is inserted. However, with this detection method, the data is relatively accurate.

3. Pipe section ultrasonic flowmeter sensor

The advantage of this form is that if there is anything that needs to be repaired without stopping the production of the detection equipment, it can be repaired directly, and the detection data is also very accurate. The manufacturer of ultrasonic flowmeters indicates that the accuracy of the detection results of the latter two installation forms is generally higher, and many detection stations also apply such detection methods.