How to maintain the probe of an ultrasonic flowmeter

The maintenance of the probe of ultrasonic flowmeters is a key link to ensure the accurate measurement and long-term stable operation of the flowmeters. The following are some specific maintenance methods and precautions:

1. Regular inspection and cleaning

Check the signal quality of the probe

Regularly check the quality of the probe signal to ensure that the signal strength remains above the level recommended by the manufacturer, usually above 90%, to guarantee the accuracy of the measurement.

Clean the probe

Regularly clean the probe to remove impurities such as scale, sediment or microbial film. These impurities may affect the signal transmission and measurement accuracy of the probe.

Clean with suitable materials and cleaning agents to avoid damaging the probe. Pay attention to following the manufacturer’s cleaning guidelines.

2. Check the installation and fastening

Check the probe installation

For the external clamp-on probe, check if there is any loosening, ensure that the adhesive or coupling agent between the probe and the pipe is in good condition, and avoid any gap between the probe and the pipe wall.

For insertable probes, check if they are installed firmly to ensure that the probes can be stably inserted into the pipeline and are not affected by external forces.

Check the connecting pipes

Check whether there is any leakage or damage to the connecting pipes to ensure the integrity of the pipeline system. Leaking or damaged pipelines may affect the measurement accuracy of the probe and even cause damage to the flowmeter.

3. Calibration and comparison

Regular calibration

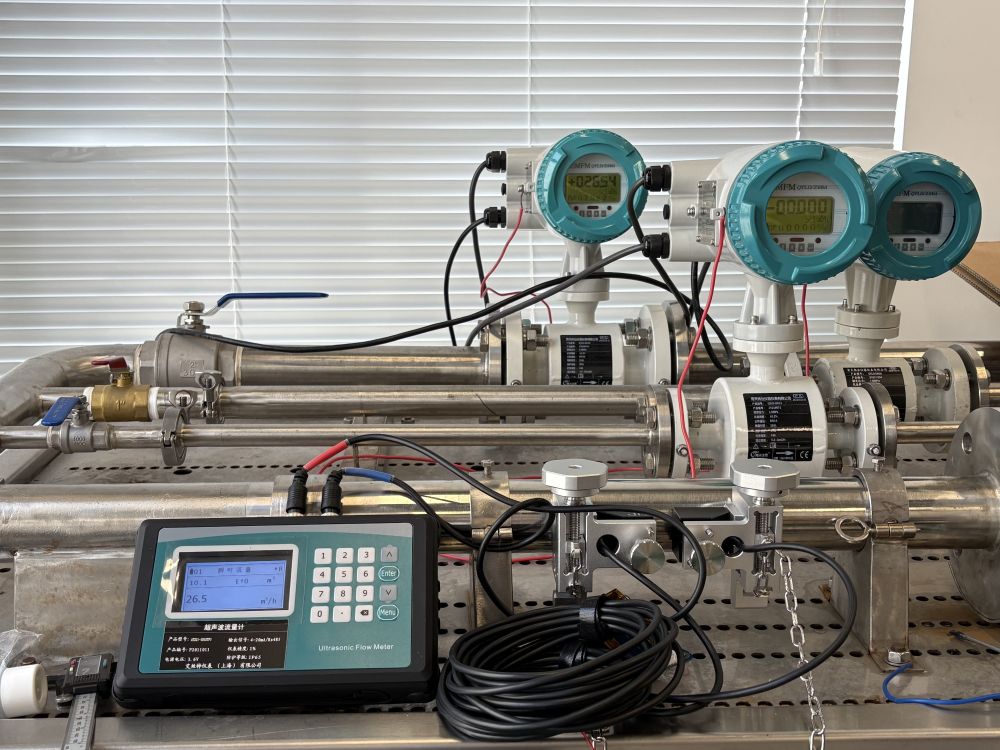

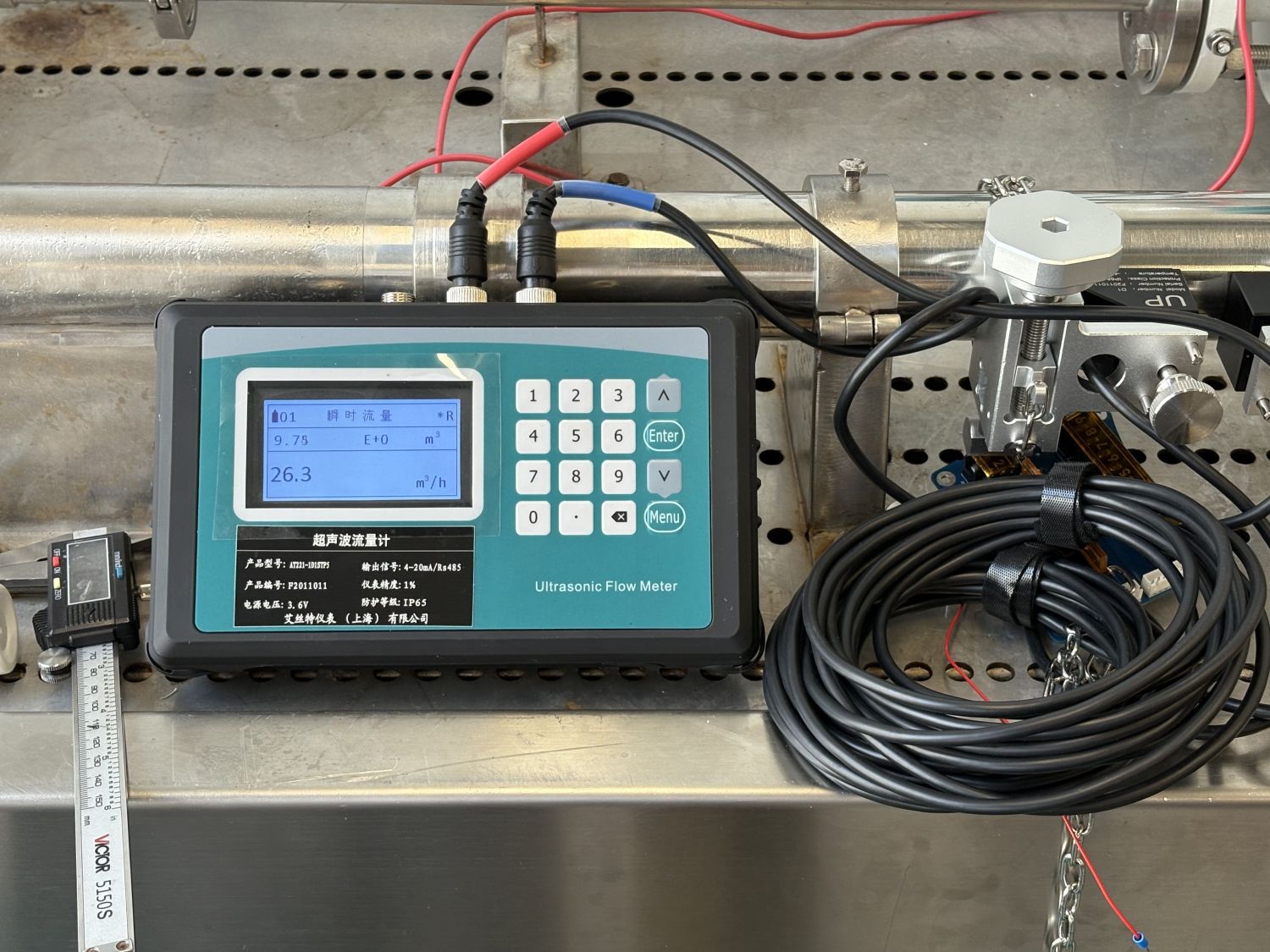

According to the manufacturer’s recommendation, calibrate the flowmeter regularly to ensure that its measurement accuracy meets the requirements. Calibration can be conducted through comparison and analysis using portable flowmeters or other standard equipment.

Comparative analysis

When conducting calibration or daily maintenance, a portable flowmeter can be used to compare and analyze the ultrasonic flowmeter in operation online to check if its measurement accuracy has changed.

4. Environmental monitoring and spare parts preparation

Monitor environmental conditions

Monitor the environmental conditions where the flowmeter is located, such as temperature, humidity, corrosiveness, etc., to ensure that it operates in a suitable environment. Harsh environmental conditions may affect the performance and lifespan of the probe.

Prepare spare parts

Keep necessary spare parts and special tools in stock so that the probe can be quickly replaced or repaired when needed. This can reduce the downtime caused by probe failure and improve production efficiency.

Summary: The maintenance of ultrasonic flowmeter probes involves multiple aspects, including regular inspection and cleaning, checking installation and tightening, calibration and comparison, environmental monitoring and spare parts preparation, as well as training and operation norms, etc. Through the implementation of these maintenance measures, the performance and lifespan of the probe can be guaranteed, thereby enhancing the measurement accuracy and stability of the ultrasonic flowmeter.