How can the measurement accuracy of ultrasonic flowmeters be improved under elbow pipes

With the development of technological progress, more and more new types of instruments have been applied to the measurement of oil fields, such as ultrasonic flowmeters and mass flowmeters. Ultrasonic flowmeters have unique advantages when used for fluid measurement. They are non-contact instruments that do not change the form of the fluid, are easy to install, can measure the flow of strongly corrosive and non-conductive media, and the measurement process is not affected by physical parameters such as temperature, pressure, density and viscosity.

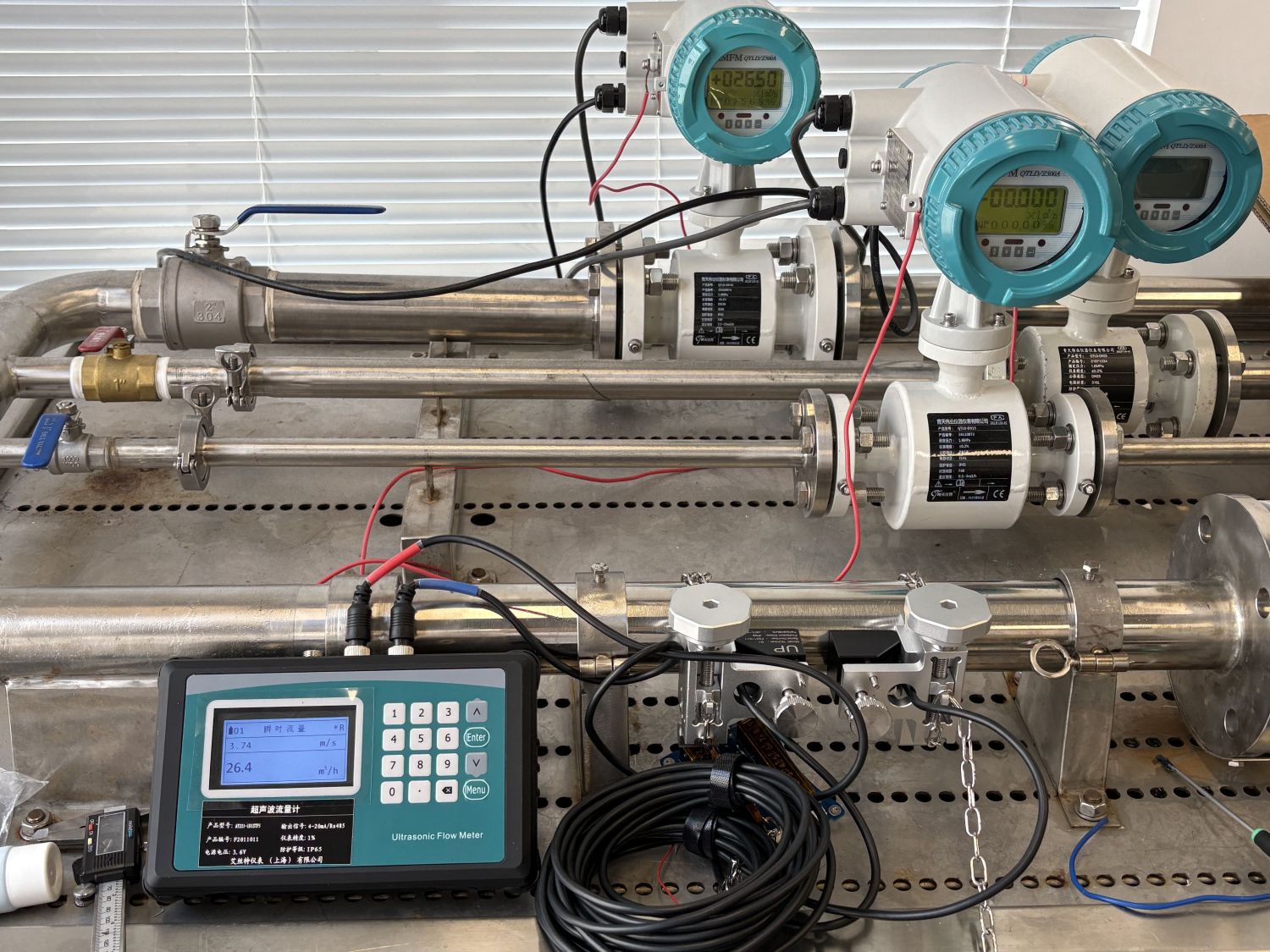

However, ultrasonic flowmeters also have some drawbacks. The main ones are poor anti-interference ability, and factors such as bubbles and scale can affect their measurement accuracy. Moreover, strict requirements are imposed on straight pipe sections during installation. Otherwise, the dispersion will be poor and the measurement accuracy will be low. When applied in the actual field of oil fields, in some application sites of ultrasonic flowmeters, there are inevitably some non-standard installation conditions, such as insufficient length of straight pipe sections and bends in the upstream.

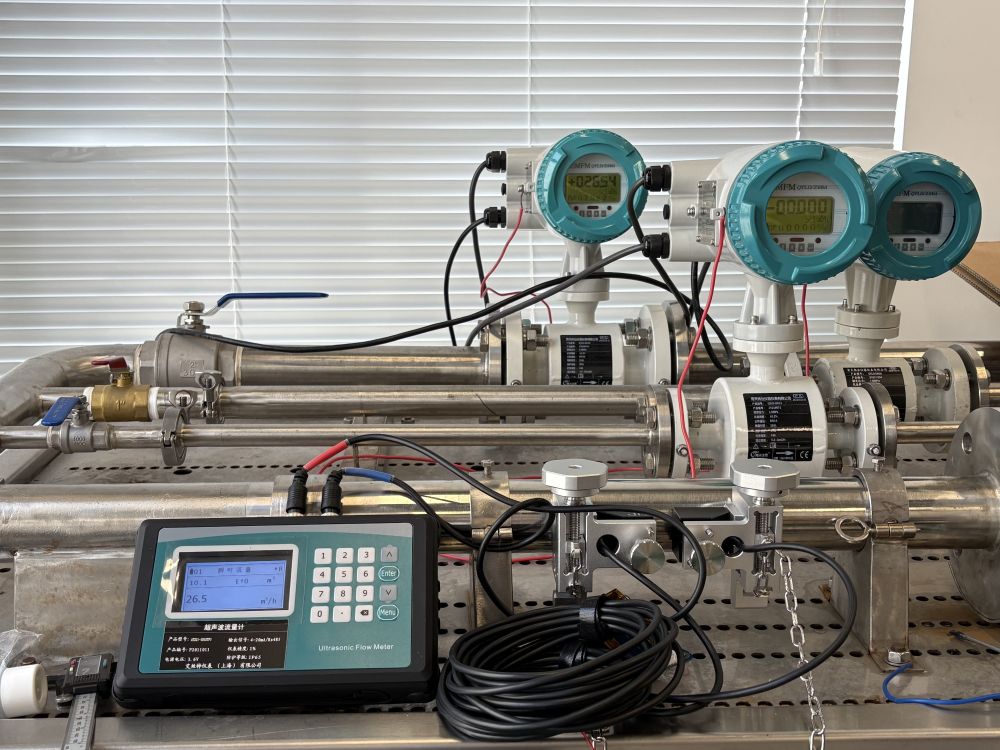

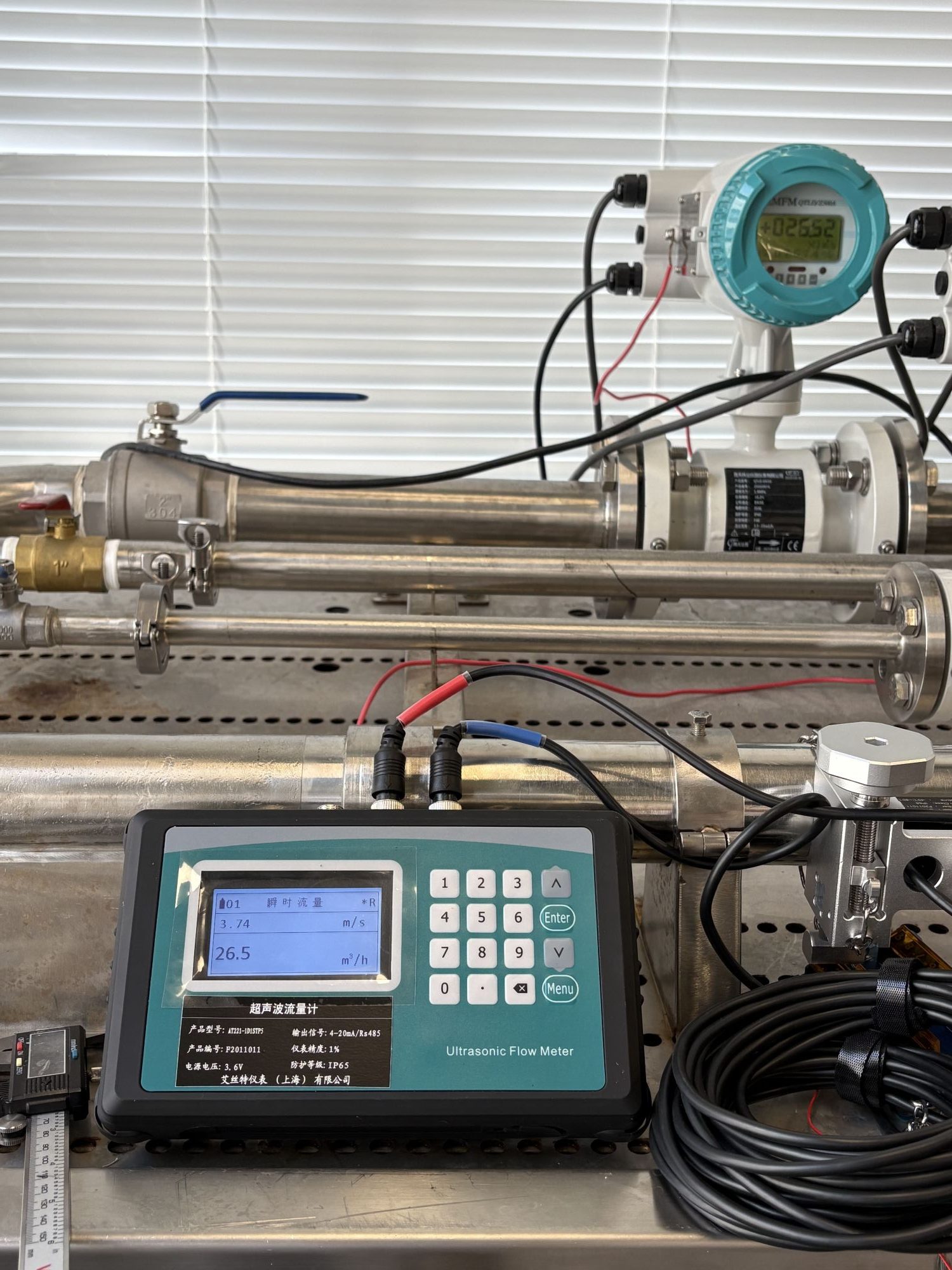

To enhance the measurement accuracy of ultrasonic flowmeters under non-standard conditions, this paper selects the portable ultrasonic flowmeter based on the time difference method, which is widely used in oil fields at present, as the research object. Through numerical simulation and field tests, the changes in measurement accuracy under the condition of elbow pipe upstream were studied, and a corresponding mathematical model was established to correct the measurement error of the ultrasonic flowmeter. This has improved the measurement accuracy of the ultrasonic flowmeter in the presence of elbow pipes.

Through the simulation study of the presence of elbow pipes upstream of the ultrasonic flowmeter, it can be known that in the case of elbow pipes, the maximum measurement error of the ultrasonic flowmeter can reach 10% at (2 to 10) D, and the error increases with the increase of flow rate. At the (10 to 15) D stage, the error of the ultrasonic flowmeter gradually decreases and changes from positive error to negative error After 15 days, the measurement error of the ultrasonic flowmeter gradually decreased and approached zero. Based on the simulation study, the fitting of the error curve correction model was carried out. After on-site test verification, the established correction model has high accuracy. After correction, the measurement indication error of the ultrasonic flowmeter can be controlled within ±1.0%, which greatly improves the measurement accuracy of the ultrasonic flowmeter under the elbow pipe.