Product Center

Contact Us

Tel:

Whatsapp

Office Hotline

Email

-

ATLD Partial Filled Electromagnetic Flow Meter

The non-full pipe flow meter is a kind of automatic flow measuring instrument that continuously measures the fluid flow in open pipelines (such as half-pipe sewage pipes and large flow pipes without overflow weirs) by using the flow rate-area method. It can measure and display the instantaneous flow rate, flow rate, cumulative flow rate and other data. It is especially suitable for the needs of measuring places such as municipal rainwater, waste water, sewage discharge and irrigation water pipes. -

ATWU Gas Ultrasonic Flow Meter

The ATWU series gas ultrasonic flowmeter is based on the principle of ultrasonic time difference method. It is equipped with independent digital temperature transmitters and pressure transmitters, and integrates a wireless remote transmission module. It is a velocity-type gas metering instrument that integrates flow measurement, volume correction and remote data transmission. -

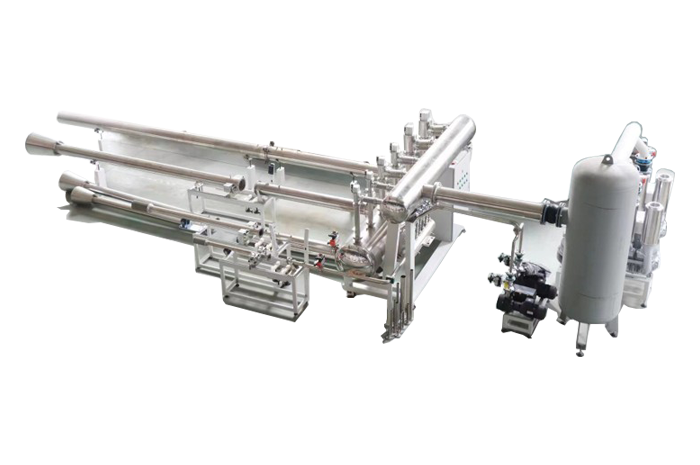

Water Flow Calibration Device

Aister Instrument Factory has many years of independent research and development, design and production experience in water flow standard devices. It can precisely calibrate various velocity flowmeters, volumetric flowmeters, mass flowmeters, etc. with diameters ranging from DN10 to DN800. -

Sonic Nozzle Gas Flow Calibration Device

Aister Instrument Factory has many years of independent research and development, design and production experience in sonic nozzle gas flow calibration devices. It can accurately calibrate various types of turbine flowmeters, vortex flowmeters, Roots flowmeters, volumetric flowmeters, velocity flowmeters, etc. with diameters ranging from DN15 to DN800. -

ATMF-C Gas Mass Flow Controller

Mass Flow Controller (MFC) used to accurately measure and control the mass flow of gas. They play an important role in scientific research and production in various fields such as semiconductors and integrated circuit industries, special materials disciplines, chemical industry, and industrial, pharmaceutical, environmental protection, and vacuum lamps. Typical applications include: electronic process equipment such as diffusion, epitaxy, CVD, oxidation, plasma etching, sputtering, and ion implantation; and coating equipment, optical fiber smelting, microreaction devices, mixed gas distribution systems, capillary measurement, Gas chromatographs and other analytical instruments -

320215.png)

ATLD Series Separated Electromagnetic Flow Meter

Electromagnetic Flowmeter is a speed instrument for measuring the volume flow of conductive medium. It can output standard current signals for recording, adjustment and control while monitoring and displaying on the spot, so as to realize automatic control of detection and remote transmission of signals. It can be widely used in the flow measurement of conductive liquid in tap water, chemical industry, coal, environmental protection, textile, metallurgy, paper making and other industries. -

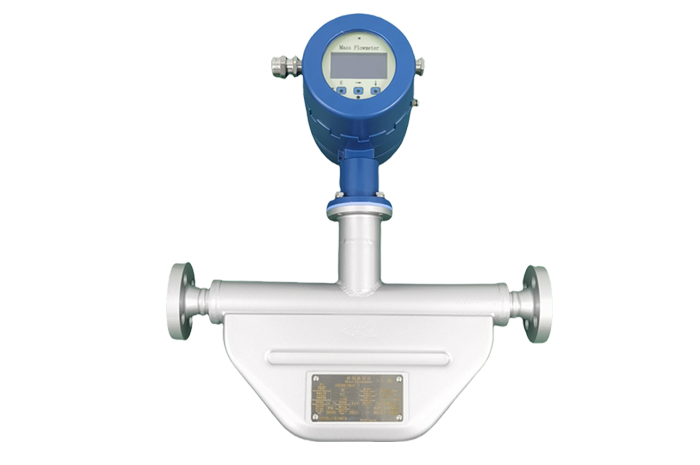

ATCMF Coriolis mass flow meter

The Coriolis Mass Flow Meter is an advanced, high-precision device designed to measure mass flow, density, and temperature of liquids and gases directly. Leveraging the Coriolis principle, it ensures highly accurate and reliable data, making it ideal for a wide range of industrial applications such as chemical processing, oil & gas, food & beverage, and pharmaceuticals. -

ATMF Micro Type Thermal Mass Flowmeter

With its high precision, wide range, stability and corrosion resistance, the ATMF Micro Type Thermal Gas Mass Flow Meter shows excellent application value in many fields such as industrial production, medical diagnosis, scientific research and environmental protection agriculture. Based on the principle of thermal diffusion, it achieves accurate measurement of gas mass flow by measuring temperature difference, provides reliable data support for process control, patient monitoring and scientific research experiments, and is an indispensable high-precision measurement tool for modern industry and scientific research. -

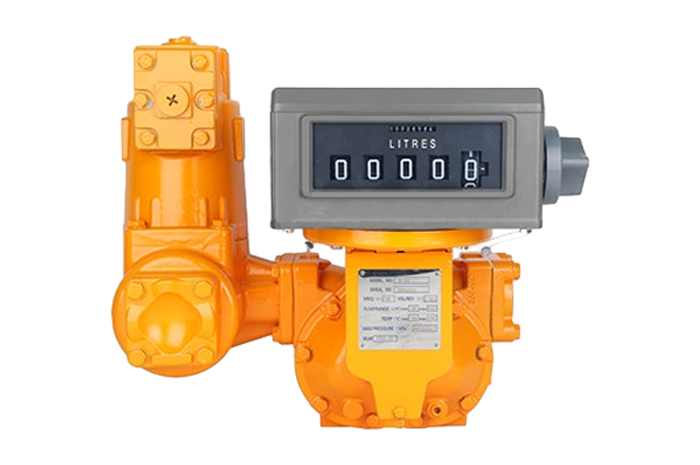

Positive Displacement Flow Meter

Aister positive displacement (PD) meters offer the ultimate in measurement accuracy for custody transfer of petroleum products, aviation fuels, LPG, and a broad range of industrial liquids.