Matters needing attention during the use of ultrasonic flowmeters

Matters needing attention during the use of ultrasonic flowmeters

1. Reasonable selection

This is very important as it is the foundation for the normal operation of ultrasonic flowmeters. If the selection is inappropriate, it may lead to consequences such as inability to measure the flow rate or inconvenience for users.

2. Reasonable installation

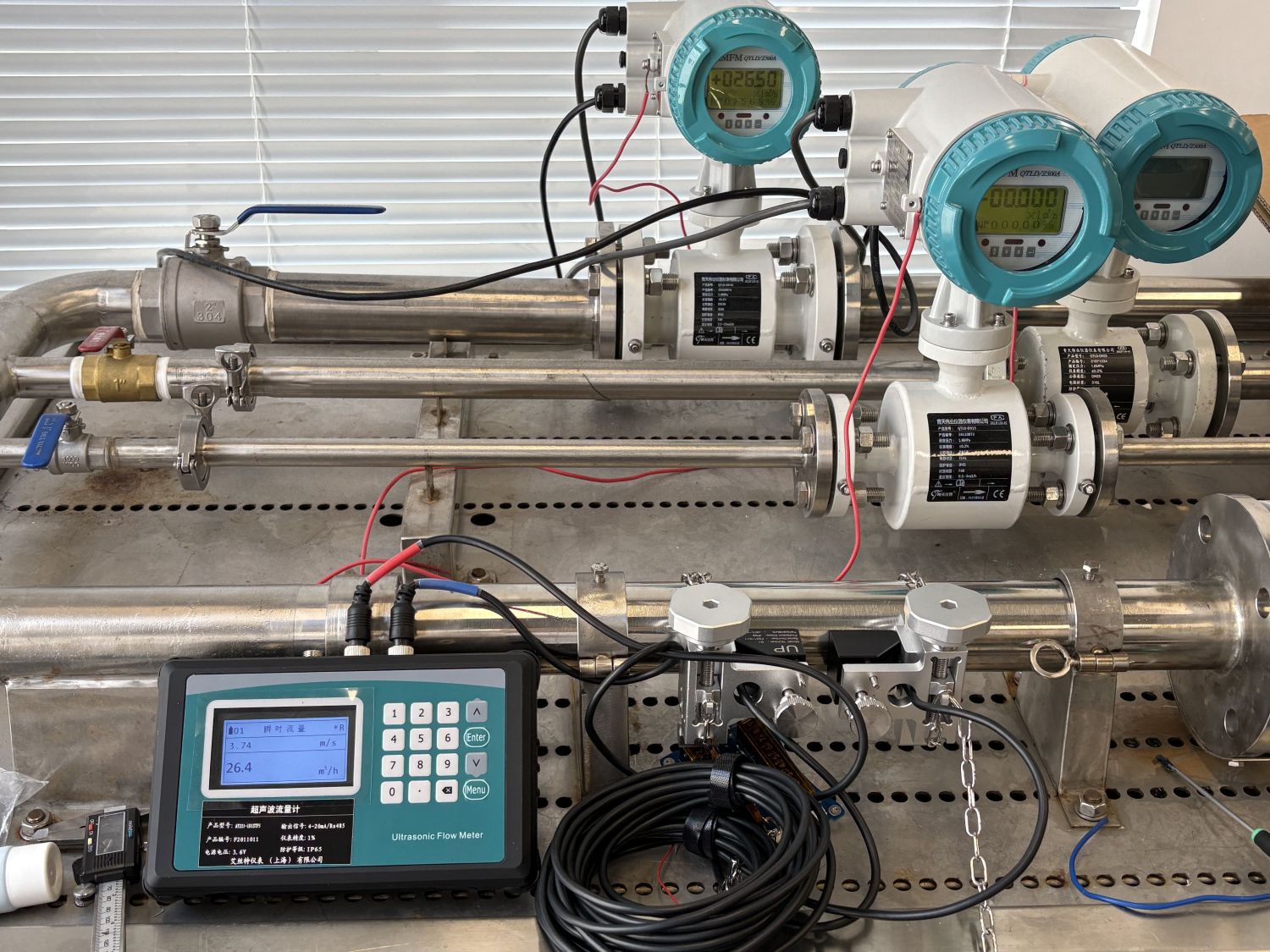

The main reason why ultrasonic flowmeters cannot work properly is the improper installation of transducers. When installing transducers, two issues need to be considered: the determination of the position and the selection of the method. When determining the position, in addition to ensuring sufficient straight pipe sections upstream and downstream, special attention should be paid to keeping the transducer away from places with variable frequency speed control noise, welding machines and other power sources that pollute the power supply. In terms of installation methods, there are mainly three types: surface mount installation, V method, and Z method. Doppler ultrasonic flowmeters are installed in a counter-attachment manner, while time difference ultrasonic flowmeters are installed in V and Z modes. Generally, when the pipe diameter is less than 300mm, V mode installation is adopted, and when the pipe diameter is greater than 200mm, Z mode installation is used. For transducers that can be installed in both V and Z modes, Z mode should be chosen as much as possible. Practical experience shows that the transducer installed in the Z mode has a high ultrasonic signal intensity and good measurement stability.

3. Timely calibration

For users who need to install large and wide-range fixed ultrasonic flow meters on-site, a portable ultrasonic flowmeter of the same type can be equipped to verify the on-site instrument conditions. First, adhere to the principle of “one installation, one calibration”, that is, verify and calibrate each newly installed ultrasonic flowmeter during installation and commissioning to ensure proper positioning, proper installation, and accurate measurement. Secondly, when there is a sudden change in the flow rate of the ultrasonic flowmeter in operation online, a portable ultrasonic flowmeter should be used for timely verification to identify the cause of the sudden change in flow rate and determine whether it is due to a malfunction of the instrument or an actual change in flow rate.

4. Regular maintenance and servicing

Compared with other flow meters, the maintenance of ultrasonic flow meters is relatively small. For external transducer ultrasonic flowmeters, after installation, there is no water pressure loss and no potential leakage. It is only necessary to regularly check whether the transducer is loose and whether the adhesive between it and the pipeline is good. For insertable ultrasonic flowmeters, it is necessary to regularly clean the impurities, scale and other deposits on the probe to check for any leakage. If it is an integrated ultrasonic flowmeter, it is necessary to check whether the flange connection between the flowmeter and the pipeline is good, and consider the influence of on-site temperature and humidity on its electronic components. Regular maintenance can ensure the stable operation of the ultrasonic flowmeter.

5. Troubleshooting

Common causes of faults in ultrasonic flowmeters and methods for troubleshooting

1) No signal: The connection line between the transducer and the main unit is disconnected. Reconnect it.

2) Power pollution caused by insufficient signal strength; The position of the transducer has been moved. Readjust the position of the transducer.

3) Inconsistency between instantaneous and cumulative flow: The main unit has malfunctioned. Replace the main unit.

4) The instantaneous flow rate is stable at 0 but higher than the actual value: The sound wedge of the transducer has malfunctioned. Replace the transducer.