What are the installation requirements for external clamp-on ultrasonic flowmeters

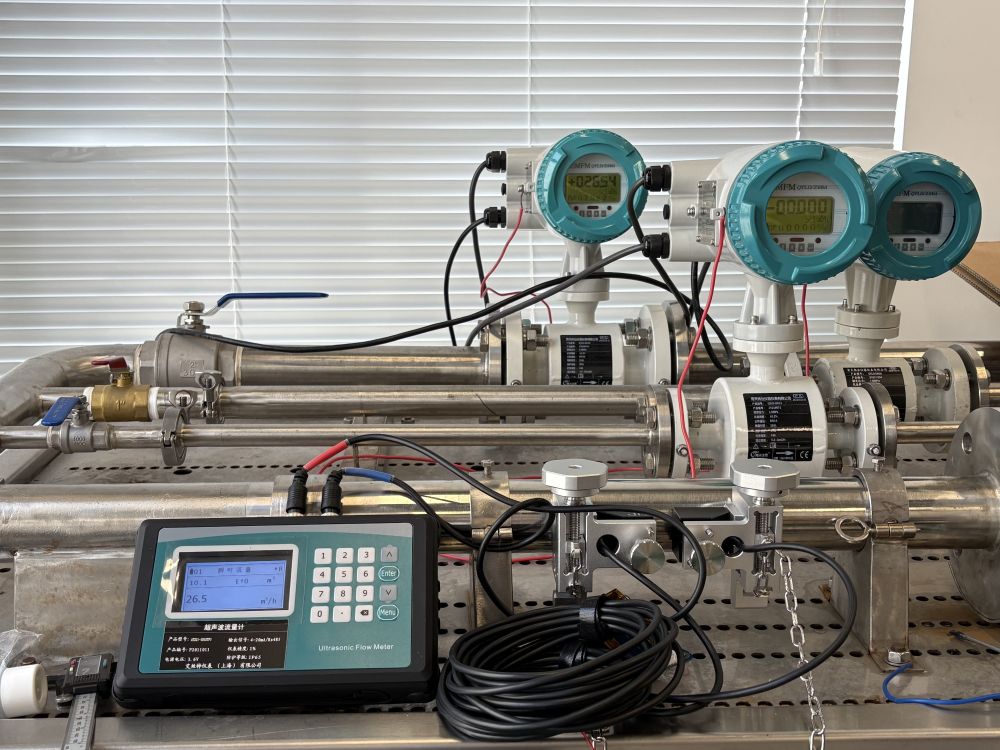

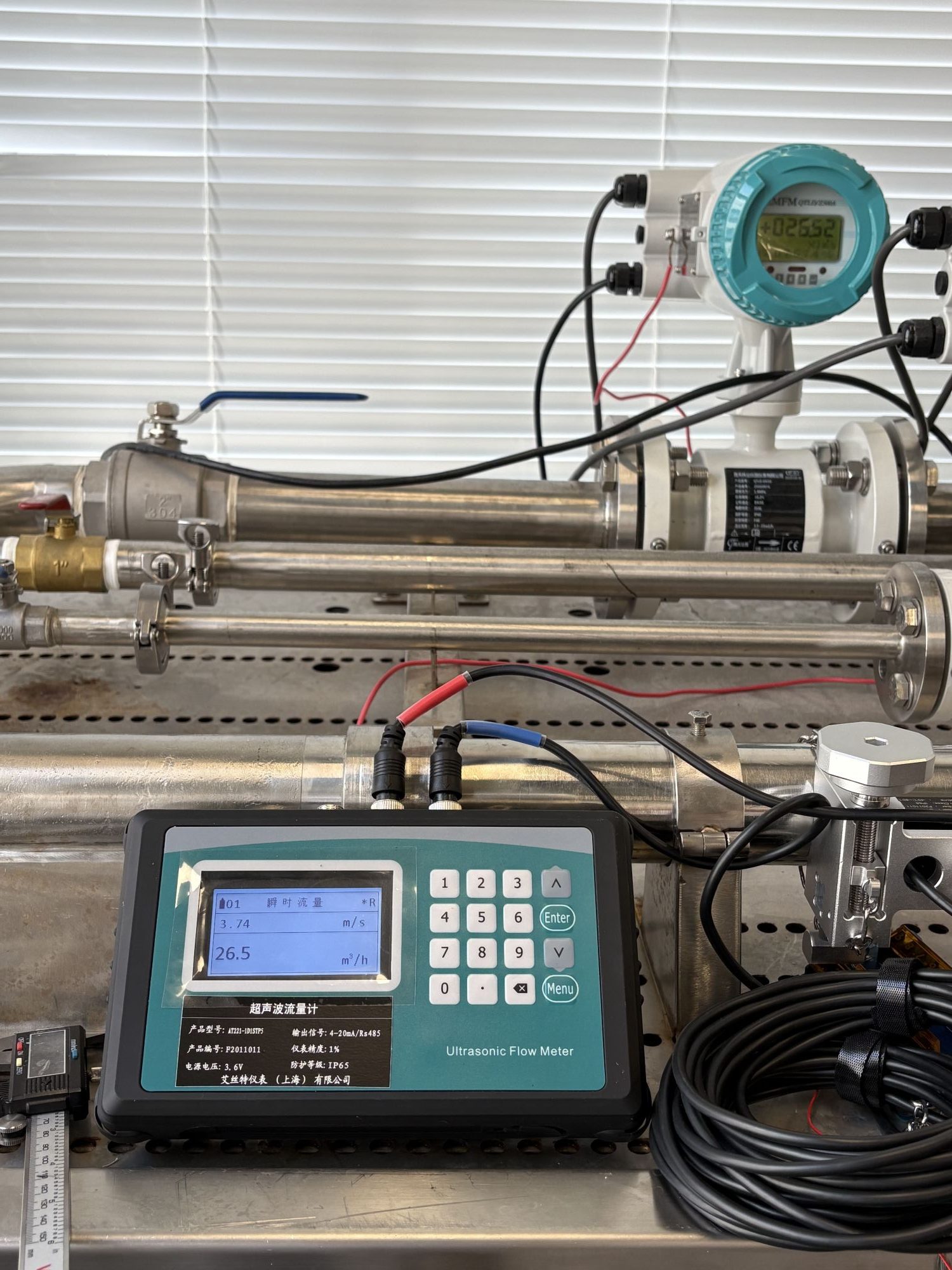

External clamp-on ultrasonic flowmeters are now widely used in many fields, such as waterworks, seawater, sewage treatment plants, diesel plants, chemical plants, and so on. However, for the values measured by this instrument to be accurate, the basic condition is correct installation. So, what are the requirements for the installation of external clamp-on ultrasonic flowmeters?

External clamp-on ultrasonic flowmeters are now widely used in many fields, such as waterworks, seawater, sewage treatment plants, diesel plants, chemical plants, and so on. However, for the values measured by this instrument to be accurate, the basic condition is correct installation. So, what are the requirements for the installation of external clamp-on ultrasonic flowmeters?

1. The external clamp-on ultrasonic flowmeter should be operated before installation

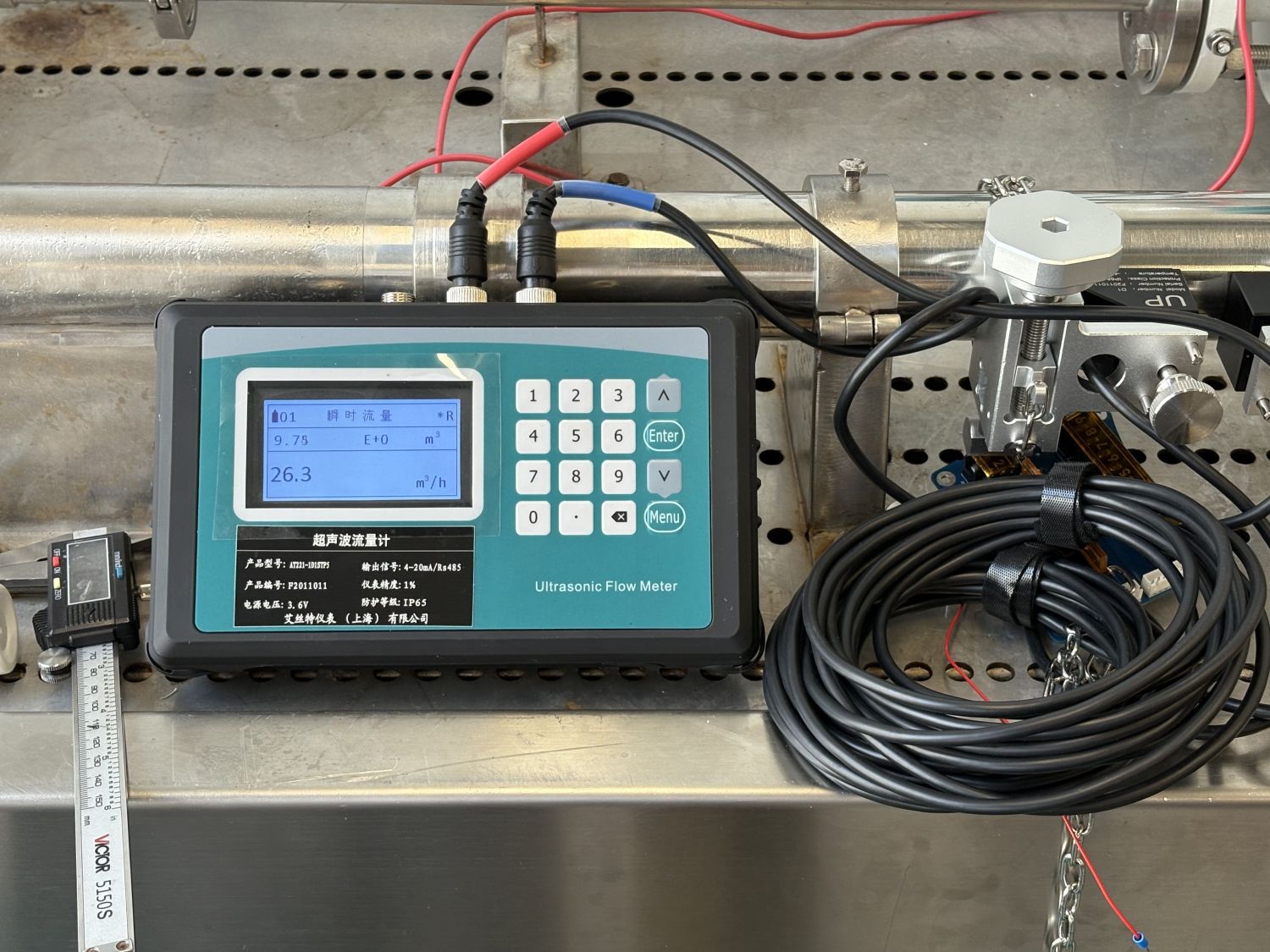

What is the distance between the sensor installation site and the main unit?

2. Temperature of the medium;

3. Whether the power supply voltage used is stable;

4. Are there any interference sources at the installation site?

5. The type of fluid, whether it contains impurities, bubbles and whether the pipe is full;

6. Pipe material, pipe wall thickness and pipe diameter;

7. Whether the location where the main unit is placed is at a constant temperature;

8. Whether remote transmission signals are needed and what types.

Ii. Selection of Installation Location for External clamp-on Ultrasonic Flowmeters

The selection of installation pipe sections has a significant impact on test accuracy. The selected pipe sections should avoid interference and eddy currents, which have a considerable influence on measurement accuracy. Generally, the selection of pipe sections should meet the following conditions:

1. The fluid should fill the pipeline.

2. Avoid installing the machine in places such as water pumps, high-power radio stations, and frequency converters, that is, in areas with strong magnetic fields and vibration interference.

3. There should be a 30D distance upstream of the installation point from the water pump.

4. The selected pipe materials should be uniform and dense, with sections that are easy for ultrasonic transmission.

5. There must be a sufficiently long straight pipe section. The straight pipe section upstream of the installation point must be greater than 10D (Note: D= diameter), and downstream must be greater than 5D.

There should be sufficient space around the pipeline to facilitate the operation of on-site personnel.