In which fields are ultrasonic flowmeters generally used

When measuring commonly used pipe diameters, ultrasonic flowmeters are not only cheaper than magnetic induction flowmeters, but also do not require additional engineering and piping work, and can be refurbished during continuous operation.

This is a very popular detection instrument nowadays and is playing its own role in different fields. Specifically, in which fields can ultrasonic flowmeters be used? What are the advantages?

1. Sewage treatment plant

Due to the continuous expansion of sewage treatment plants and the increasingly strict requirements for advanced wastewater treatment, it is necessary to improve the pipeline system in a more reliable way. At present, most of the flowmeters on the market use electromagnetic induction type. Due to the fact that the medium is filled with a large amount of solid substances, it is very easy to cause instrument wear and tear, thereby affecting the reading

Counting errors and subsequent malfunctions are time-consuming and laborious to handle. The ultrasonic flowmeter can be selected as an external clamping type, which has no contact with the medium, no wear and tear, and almost no maintenance is required, making its advantages more obvious.

2. Regarding oil transportation

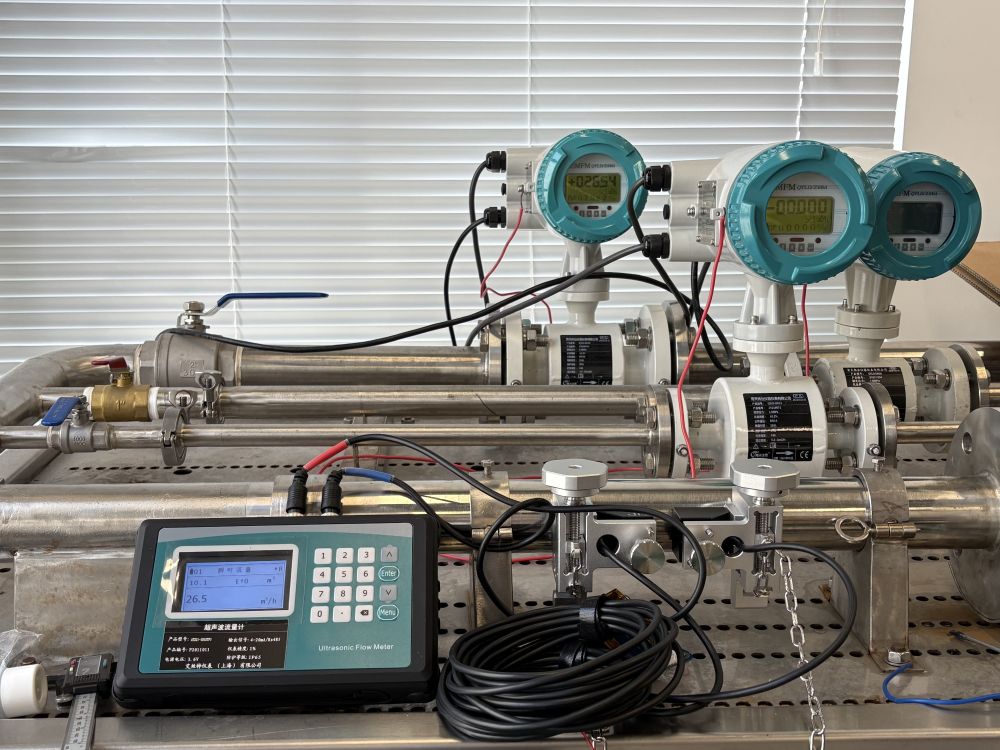

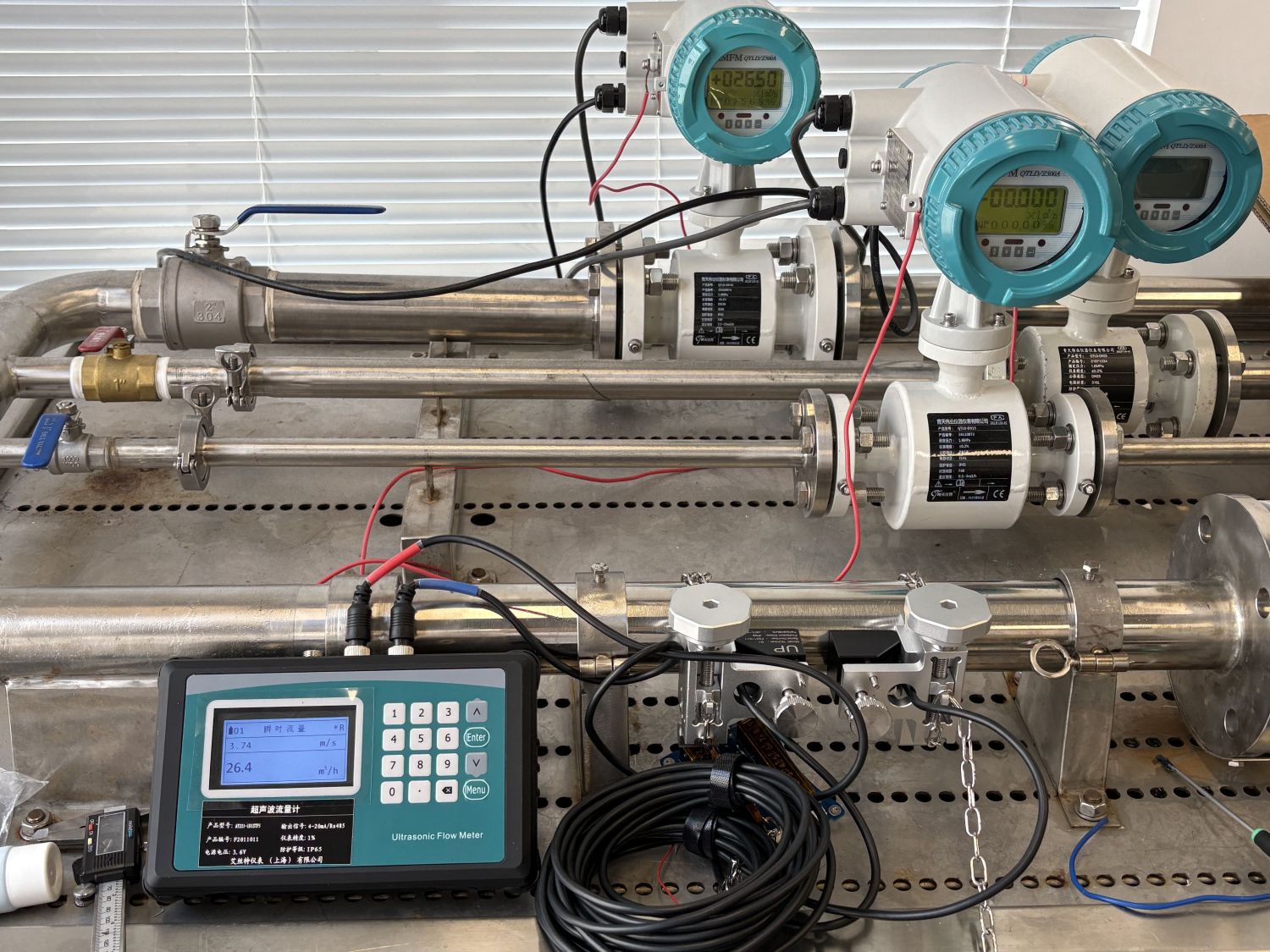

In the oil and gas industry, the safe and effective transportation of oil is of great significance. External clamp type and portable ultrasonic flowmeters can accurately measure flow rate, flow velocity and cumulative volume, and have almost no impact on the pipeline or the oil inside the pipeline. It also has the alarm functions of monitoring flow rate, the number of valves opened and closed, and whether there is leakage.

3. Building measurement

The demand for building energy optimization is extremely high. For instance: reducing overall energy consumption, improving the performance of HVAC systems, lowering operating costs, enhancing building quality and certification levels, and so on. Of course. There are also more environmentally friendly ideas. There are many methods to TL to improve energy efficiency. There is no doubt that controlling the flow of sleep and air conditioning in buildings is an important aspect. When measuring, ultrasonic flowmeters are adopted to achieve the purpose of no moving parts, stable detection and simple daily maintenance.