The wiring method of ultrasonic flowmeters

The wiring methods of ultrasonic flowmeters mainly involve power lines, signal lines and possible communication lines, etc. The following are the detailed steps for wiring ultrasonic flowmeters based on multiple authoritative sources:

1. Power cord wiring

Ultrasonic flowmeters typically have two types of power supplies: AC and DC. The specific type of power supply to be used should be determined based on the requirements of the flowmeter and the on-site conditions.

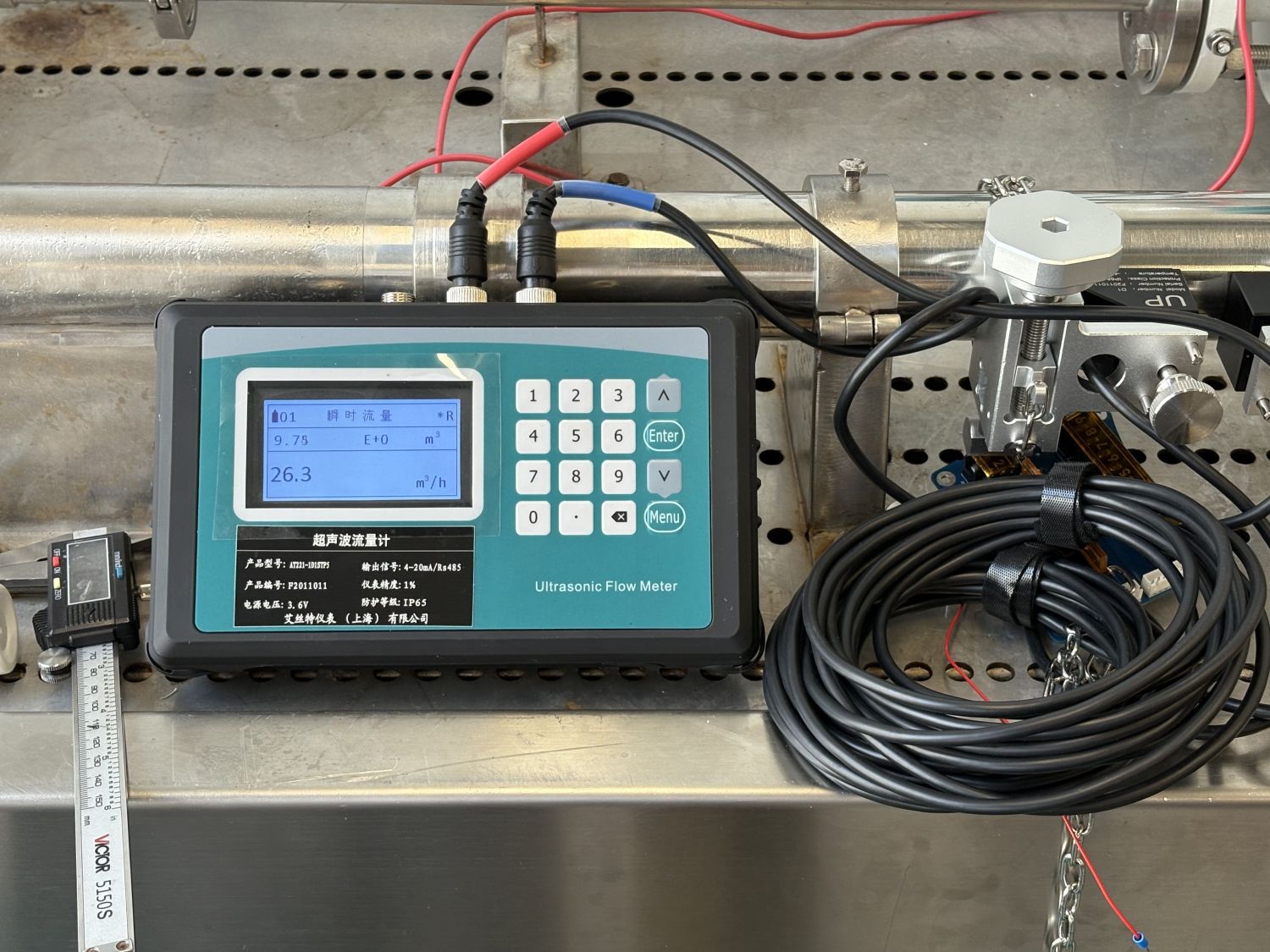

DC power supply (DC)

Red line: Connect to the +VDC power supply, that is, the positive terminal of the power supply.

Black wire: Connect to the 0V power supply, that is, the negative terminal of the power supply.

Before wiring, it is necessary to confirm whether the voltage and current of the power supply are in line with the rated parameters of the ultrasonic flowmeter to avoid damaging the equipment.

AC power supply (if applicable) :

Some models of ultrasonic flowmeters may support AC power input. For specific wiring methods, please refer to the equipment manual.

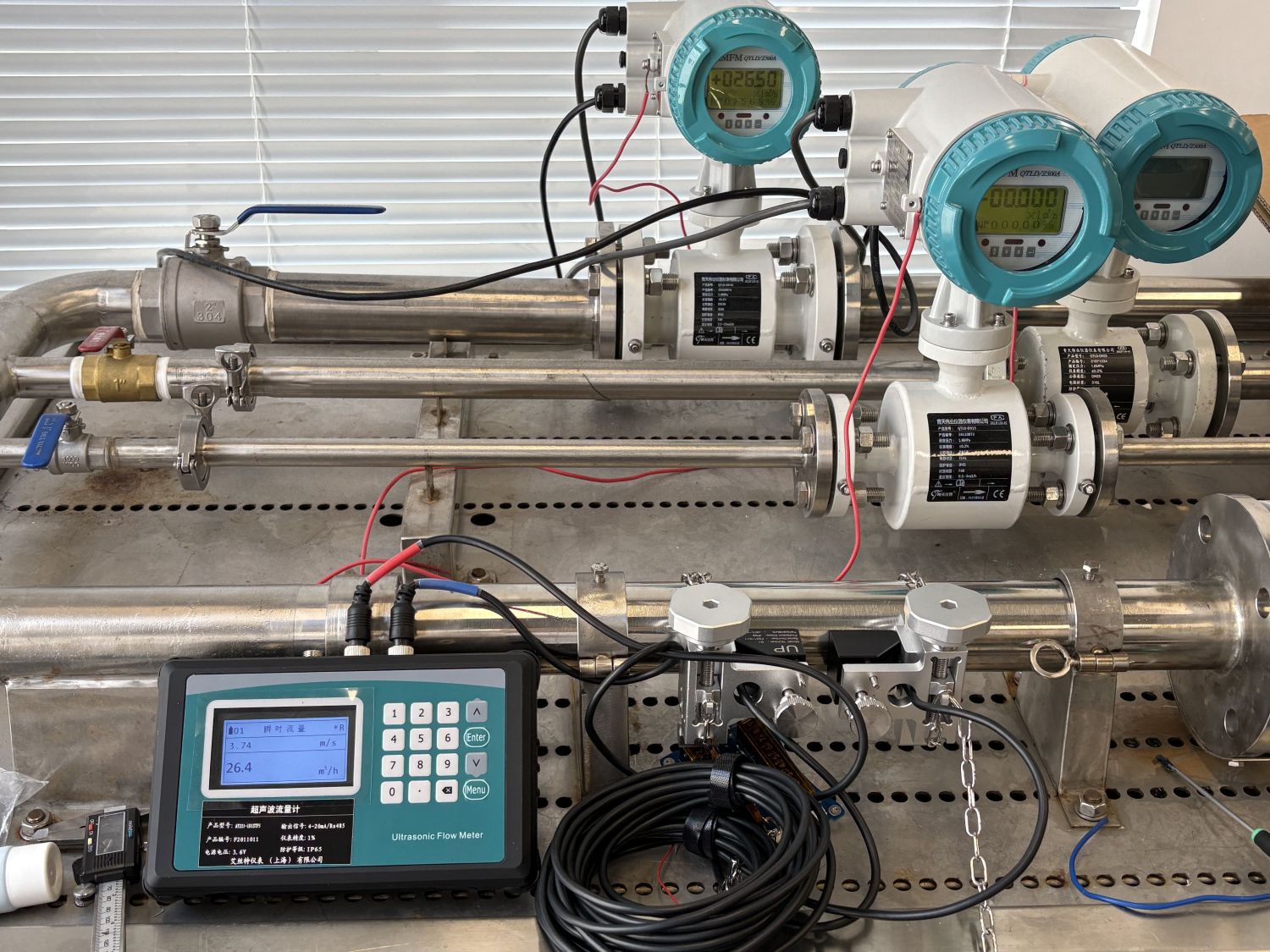

2. Signal line wiring

White line (or other line marked as signal output) : Connected to the output signal line, usually to the input terminal of the PLC controller or display. This signal line is used to transmit the measurement data of the flowmeter.

3. Other possible wiring

4-20mA current output wiring

Some ultrasonic flowmeters offer a 4-20mA current output for remote transmission of measurement values. When wiring, the positive and negative poles must be correctly connected to the corresponding ports of the receiving device.

RS485 communication wiring

If the ultrasonic flowmeter supports the RS485 communication protocol, it needs to be wired in accordance with the RS485 communication specification to achieve communication with the upper computer or other devices.

Grounding wire

The cable of an ultrasonic flowmeter usually contains a yellow-green wire as the grounding wire. This wire should be connected to the grounding screw to ensure the safety and stable operation of the equipment.

4. Wiring precautions

Read the manual: Before wiring, be sure to read the manual of the ultrasonic flowmeter carefully to understand the electrical characteristics and wiring requirements of the equipment.

Power-off operation: During the wiring process, it is necessary to ensure that the equipment is in a power-off state to avoid electric shock and damage to the equipment.

Check the cables: Regularly inspect the cables of the ultrasonic flowmeter to ensure they are free from damage, aging or loosening. If any are found, they should be replaced or tightened in time.

Cleaning and maintenance: Keep the sensor of the ultrasonic flowmeter clean to ensure measurement accuracy. During use, dirt and deposits on the surface of pipelines and sensors should be cleaned in a timely manner.

Professional installation: For complex or high-demand installation environments, it is recommended that professionals carry out installation and commissioning.

The above information is for reference only. The specific wiring method still needs to be operated according to the model of the ultrasonic flowmeter and the manual provided by the manufacturer. If you have any questions or uncertainties, please consult the manufacturer or professional technicians.