What should I do if the indicated value of the electromagnetic flowmeter is unstable?

The reasons for this situation may be that the mechanical zero point of the electromagnetic flowmeter is set, the error is corrected, various technical and on-site requirements are not paid attention to

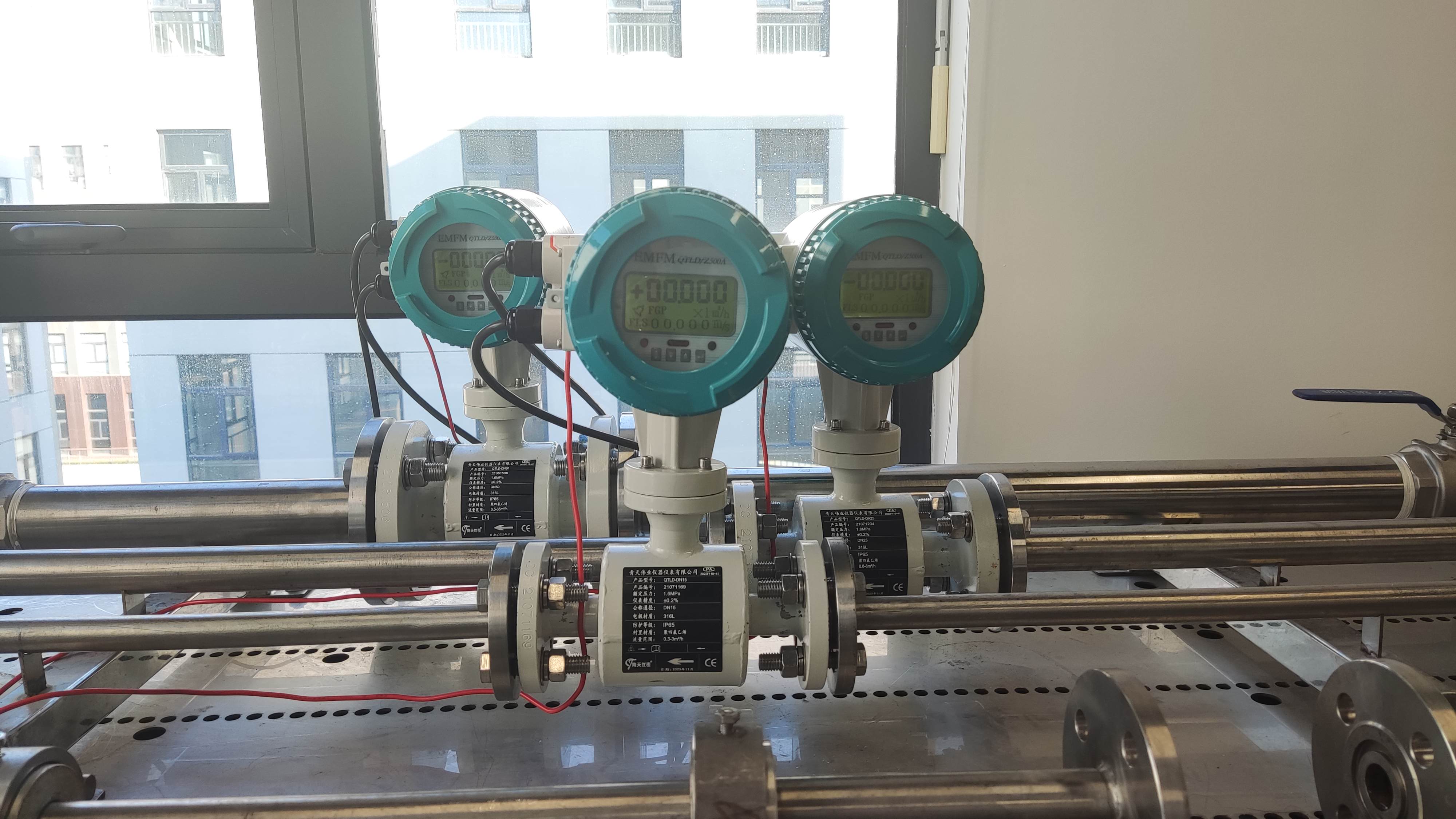

The reasons for this situation may be that the mechanical zero point of the electromagnetic flowmeter is set, the error is corrected, various technical and on-site requirements are not paid attention to, the sensor is set at an incorrect position, the length of the straight pipe sections before and after the sensor is incorrect, the liquid does not meet the requirements of the entire pipeline, or during the process of the converter parameter change, such as the electrode resistance and insulation resistance of a large number of bubbles The fluid flow in the pipeline does not meet the measurement requirements. Inspection and handling can be carried out in the following ways.

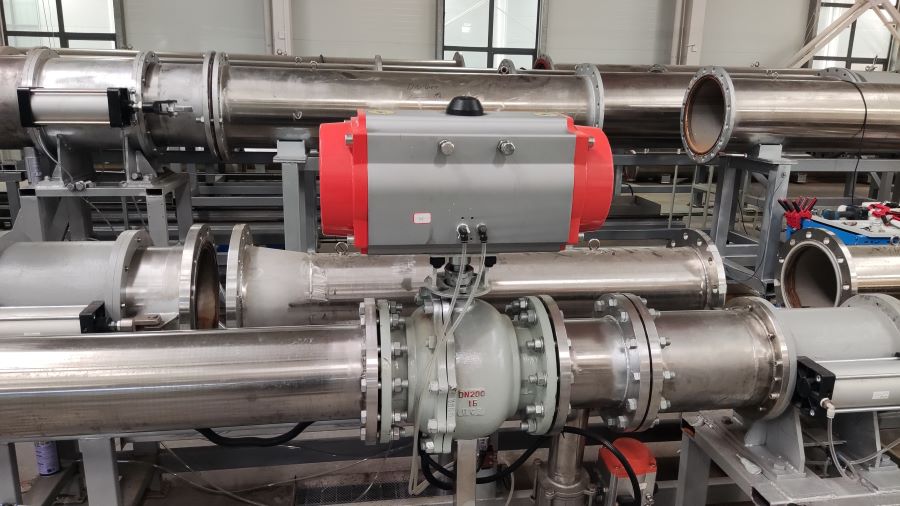

Compare the historical data of the measuring instrument with the measurement results of other types of flowmeters, and make certain estimations based on the materials of the entire process to ensure that the data during the process is basically the same as that of the measuring instrument, which is convenient for the instrument maintenance worker to judge and handle faults.

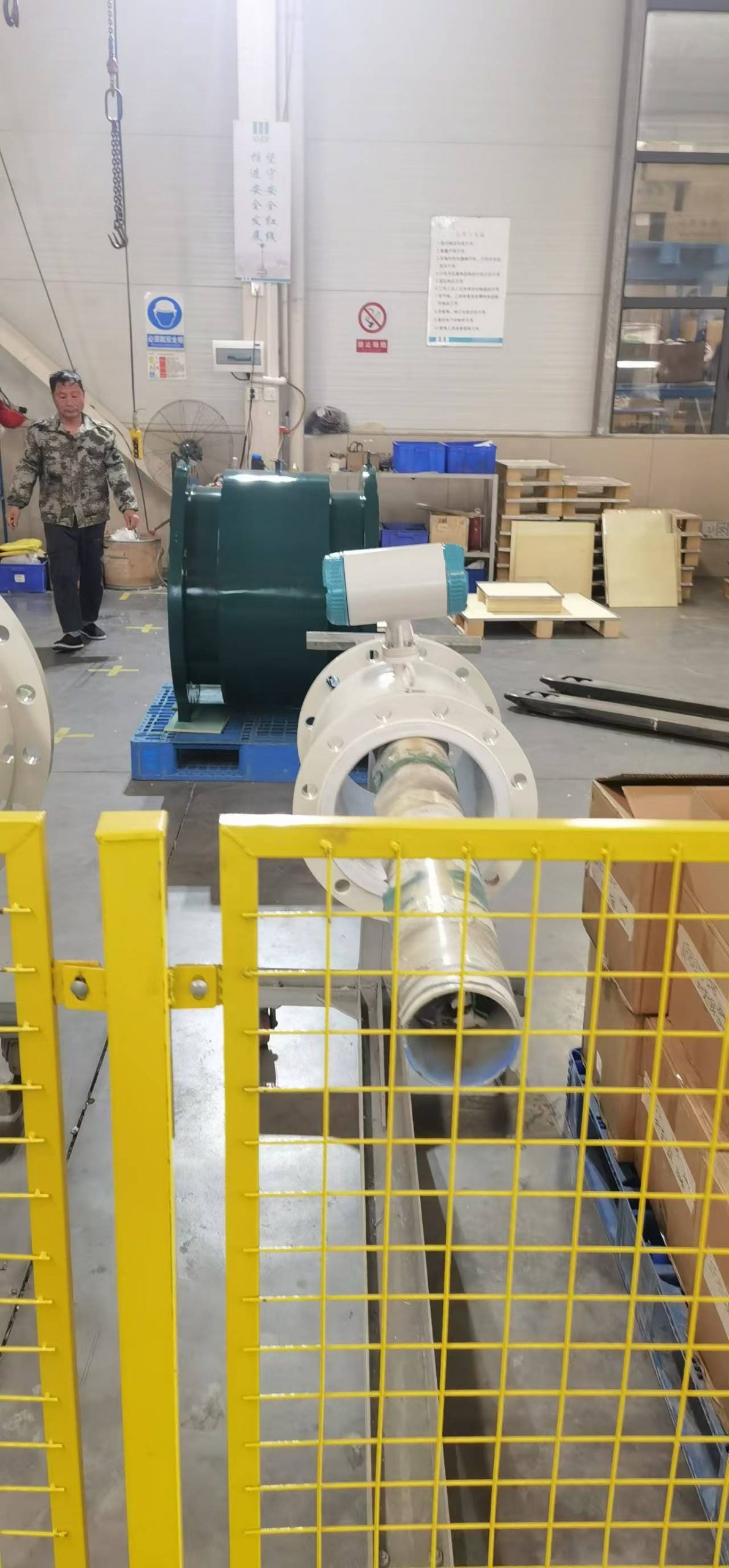

2. When the electromagnetic flowmeter detects incorrect measurement data, first check whether the sensor and the converter are consistent, and determine whether the diameter, range, unit, etc. are correctly set. The zero point of the converter can be checked for a large value by inputting an analog signal.

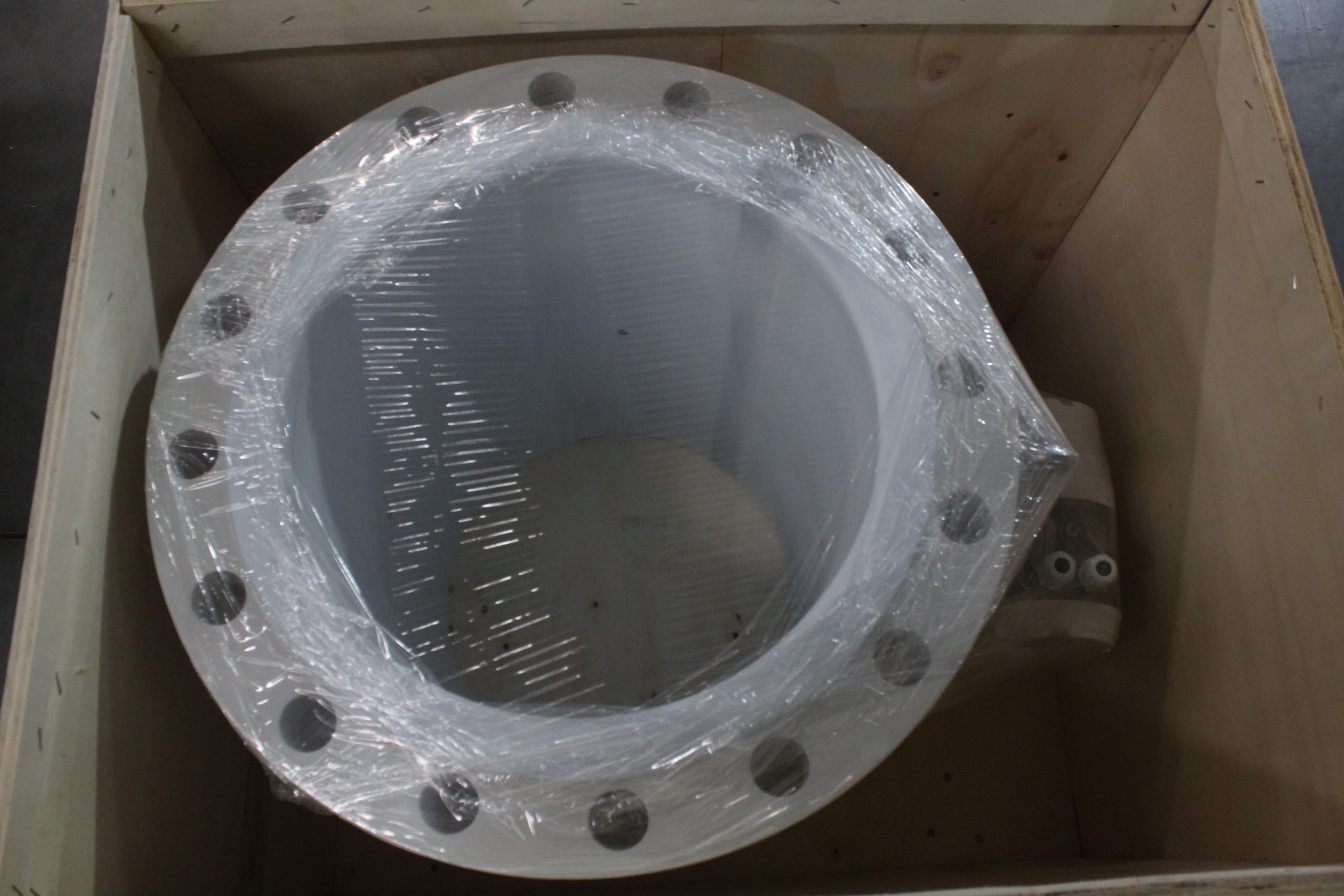

3. Check whether the connection between the line and the port is loose and whether the zero grounding between the wire and the electromagnetic shield complies with the process standards. Use a multimeter to measure the insulation resistance of the electrode. The sensor needs to be powered off. First, remove the sensor, drain the liquid in the pipeline, clean the lining, and measure the resistance values of the two electrodes and the flange with a multimeter.

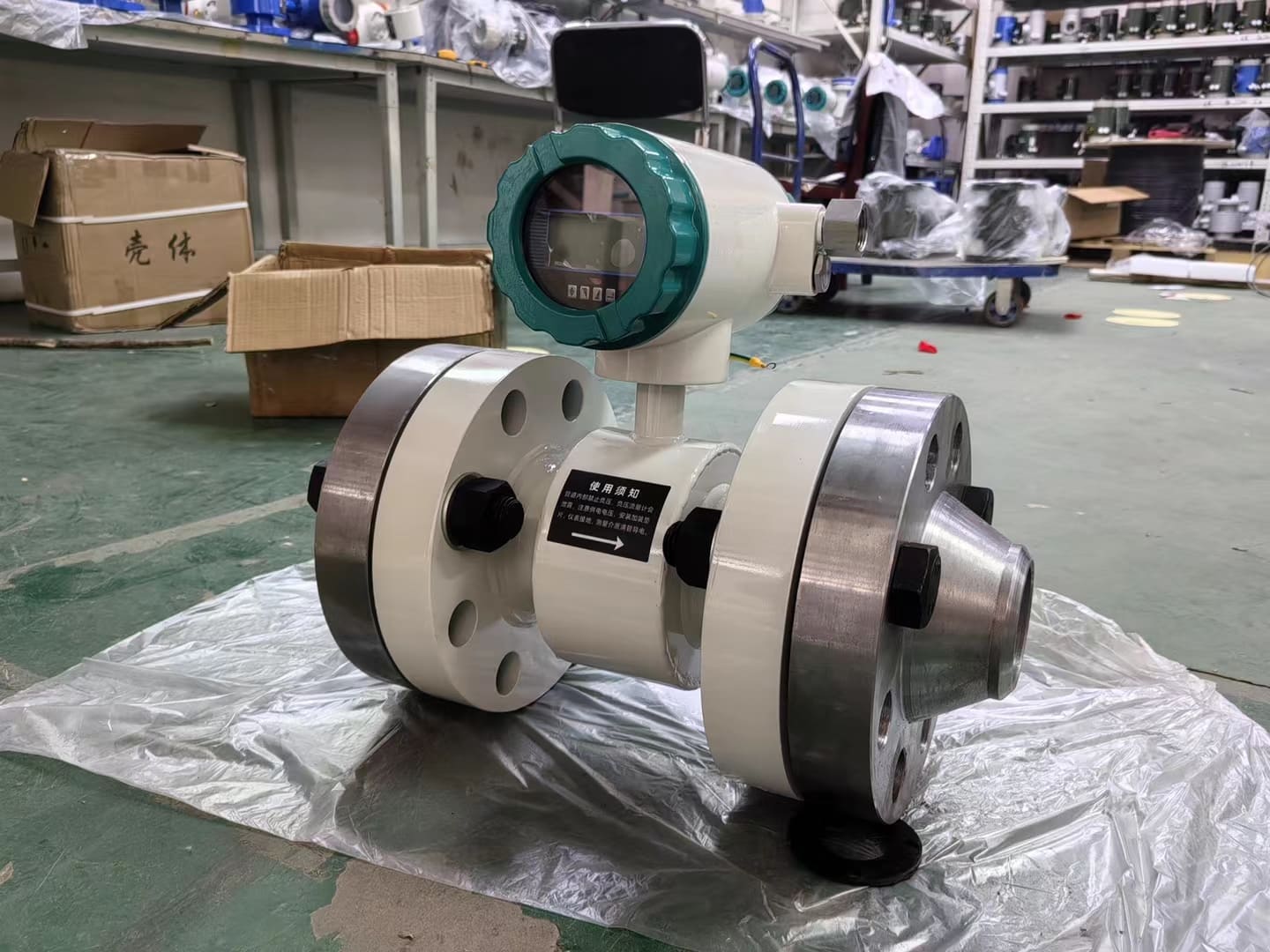

4. The sensor of the electromagnetic flowmeter is greatly affected by the process medium. When disassembling the sensor, it is necessary to clean and tidy the inner wall of the sensor, and carefully check whether there are burrs, protrusions and garbage on the inner wall. This will reduce the insulation resistance of the electrode and be measured.